At its core, the primary advantage of a tube furnace's design is its ability to create an exceptionally uniform and precisely controlled heating environment. This tubular structure is not an arbitrary choice; it is engineered to deliver reliable high-temperature performance while minimizing temperature gradients that could otherwise compromise the integrity of sensitive materials and processes.

The decision to use a tube furnace stems from a need for precision. Its design directly solves the critical challenge of achieving uniform heat distribution in a compact, controlled, and often atmosphere-specific environment, something less specialized ovens cannot guarantee.

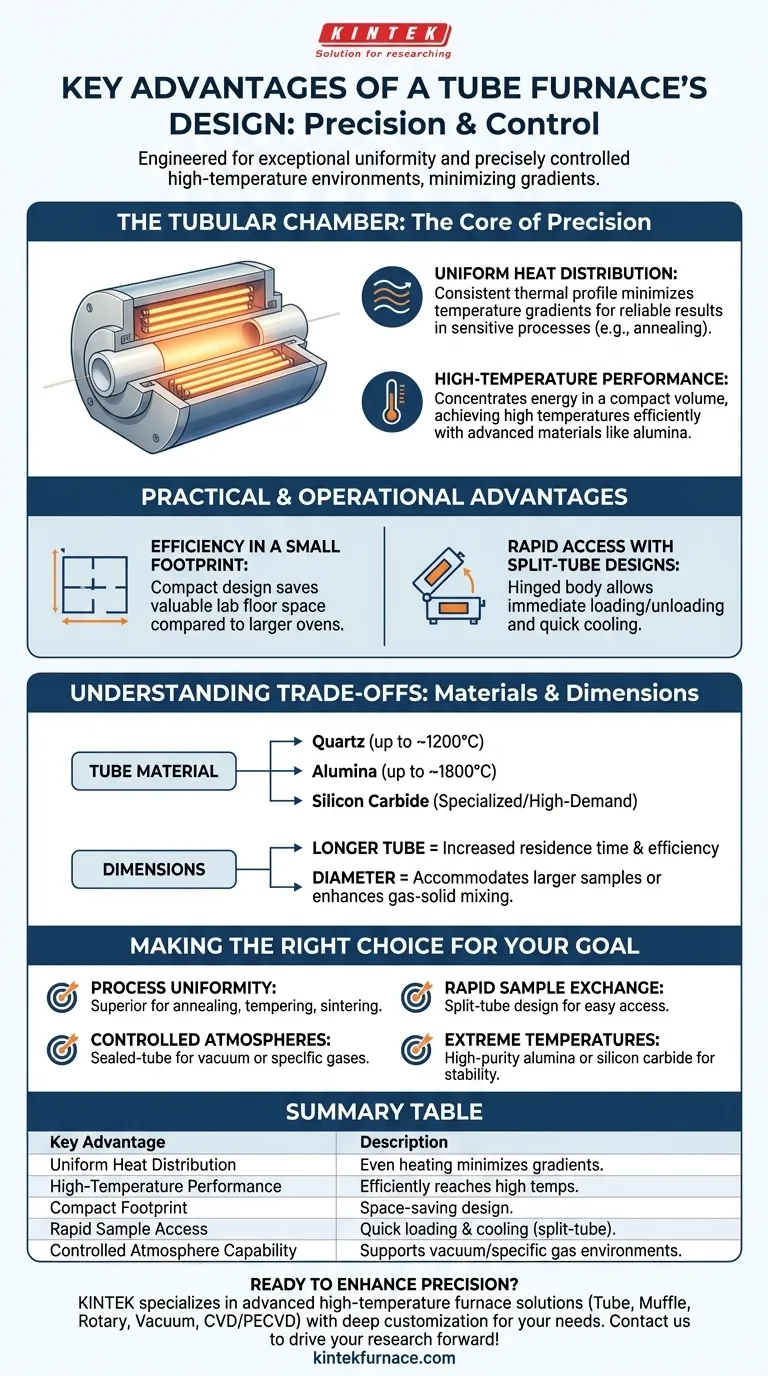

The Tubular Chamber: The Core of Precision

The defining feature of this furnace is its long, narrow chamber. This geometry is fundamental to all its other advantages, directly influencing temperature stability and uniformity.

The Foundation: Uniform Heat Distribution

A tube furnace excels at distributing heat evenly along the length of its heating zone. Heating elements surround the tube, creating a consistent thermal profile.

This design significantly reduces temperature gradients, ensuring that the entire sample is subjected to the same thermal conditions. This is critical for processes like annealing or crystal growth, where even minor temperature variations can ruin an outcome.

The Goal: High-Temperature Performance

The enclosed, compact nature of the tube allows the furnace to reach and maintain high temperatures efficiently. The design concentrates energy within a small volume.

To handle this intensity, these furnaces often require advanced materials, such as high-temperature alloy tubing and specialized ceramics, ensuring reliable and stable operation under demanding conditions.

Practical and Operational Advantages

Beyond thermal precision, the physical design of a tube furnace offers significant benefits for laboratory and industrial workflows. These features address practical constraints like space and ease of use.

Efficiency in a Small Footprint

Compared to larger box furnaces or industrial ovens with similar temperature capabilities, tube furnaces are remarkably compact.

Their high efficiency and smaller footprint make them an ideal solution for research labs and production facilities where floor space is a valuable commodity.

Rapid Access with Split-Tube Designs

Many tube furnaces feature a "split-tube" design, where the furnace body is hinged and can be opened lengthwise. This provides immediate, unobstructed access to the work tube and sample.

This feature is invaluable for applications requiring complex setups inside the tube or for processes where samples must be cooled rapidly, as opening the furnace allows heat to dissipate quickly.

Understanding the Trade-offs

Choosing a tube furnace involves considering how its components will interact with your specific process. The tube itself is not a one-size-fits-all component; its material and dimensions are critical variables.

Tube Material Dictates Application

The work tube's material is the primary factor limiting the maximum operating temperature and chemical compatibility.

Quartz tubes are common for temperatures up to approximately 1200°C but can be reactive with certain elements. Alumina tubes offer higher temperature resistance (up to 1800°C) and durability. Other materials like silicon carbide are used for specialized, high-demand applications.

Dimensions Influence Process Dynamics

The length and diameter of the tube are not just about sample size; they directly affect the process itself.

A longer tube can increase the "residence time" a material spends in the hot zone, improving reaction efficiency. A wider diameter can accommodate larger samples, while a narrower diameter can enhance gas-solid mixing for certain chemical vapor deposition (CVD) processes.

Making the Right Choice for Your Goal

The optimal tube furnace configuration depends entirely on your specific scientific or industrial objective.

- If your primary focus is process uniformity: The inherent design provides an unparalleled stable heating zone, making it the superior choice for annealing, tempering, and sintering.

- If your primary focus is rapid sample exchange: A split-tube furnace design offers the easiest access for loading, unloading, and in-situ adjustments.

- If your primary focus is working with controlled atmospheres: The sealed-tube design is perfect for creating vacuum conditions or introducing specific process gases, a key requirement for material synthesis and purification.

- If your primary focus is reaching extreme temperatures: Pay close attention to the tube material, as a high-purity alumina or silicon carbide tube will be necessary to ensure stability and longevity.

Ultimately, the advantages of a tube furnace are realized when its design features are correctly matched to the demands of your application.

Summary Table:

| Key Advantage | Description |

|---|---|

| Uniform Heat Distribution | Even heating along the tube length minimizes temperature gradients for consistent results. |

| High-Temperature Performance | Efficiently reaches and maintains high temperatures with advanced materials like alumina or quartz. |

| Compact Footprint | Space-saving design ideal for labs with limited floor space. |

| Rapid Sample Access | Split-tube models allow quick loading, unloading, and cooling. |

| Controlled Atmosphere Capability | Sealed tubes support vacuum or specific gas environments for synthesis. |

Ready to enhance your lab's precision and efficiency? KINTEK specializes in advanced high-temperature furnace solutions, including Tube Furnaces, Muffle Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With our strong R&D and in-house manufacturing, we offer deep customization to meet your unique experimental needs—whether for uniform heating, rapid access, or controlled atmospheres. Contact us today to discuss how our tailored solutions can drive your research and production forward!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- How do vertical tube furnaces comply with environmental standards? A Guide to Clean, Efficient Operation