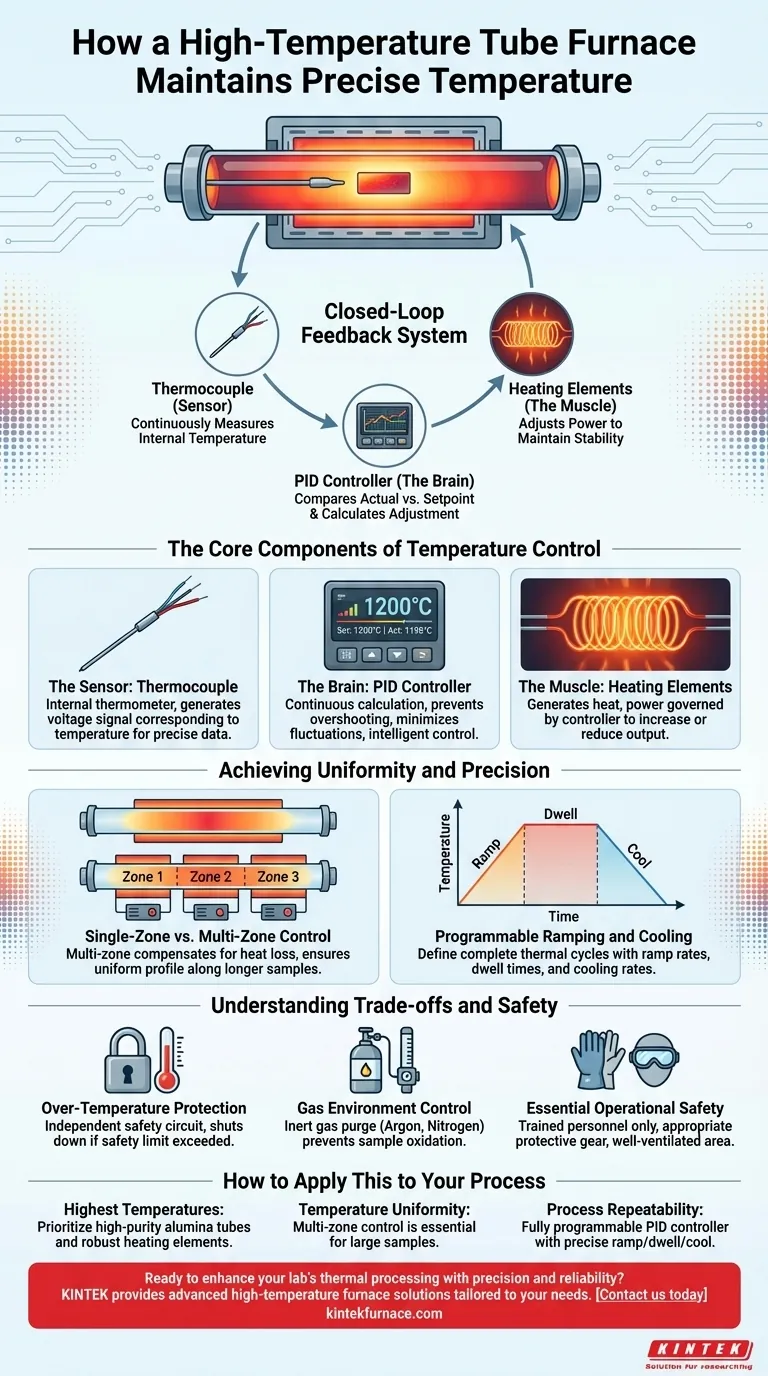

At its core, a high-temperature tube furnace maintains its set temperature through a sophisticated closed-loop feedback system. A sensor, typically a thermocouple, continuously measures the internal temperature and sends this data to a controller. This controller then compares the actual temperature to the desired setpoint and precisely adjusts the power sent to the heating elements to eliminate any difference.

The furnace doesn't simply get hot; it achieves and holds a precise thermal state. This is accomplished by a constant cycle of measuring, comparing, and adjusting, managed by an intelligent control system to ensure stability and uniformity.

The Core Components of Temperature Control

A high-temperature tube furnace operates as a complete system. Understanding the role of each primary component is key to understanding how it achieves such precise control.

The Sensor: The Thermocouple

A thermocouple acts as the furnace's internal thermometer. It is placed inside the furnace chamber to get an accurate reading of the process temperature.

This sensor generates a tiny voltage signal that corresponds directly to the temperature it detects. High-resolution thermocouples provide more precise data, allowing the control system to react to even minor fluctuations.

The Brain: The PID Controller

The signal from the thermocouple is fed into a PID (Proportional-Integral-Derivative) controller, which is the brain of the operation.

The controller performs a continuous, rapid calculation. It compares the actual temperature from the thermocouple to the user-programmed setpoint and determines exactly how much power the heating elements need to close the gap. This advanced control prevents overshooting the target temperature and minimizes fluctuations.

The Muscle: The Heating Elements

The heating elements are the components that actually generate the heat inside the furnace. The PID controller's output signal directly governs the amount of electrical power they receive.

When the controller detects the temperature is too low, it increases power to the elements. As the temperature approaches the setpoint, it reduces power, creating a stable thermal environment.

Achieving Uniformity and Precision

Holding a single point at the right temperature is only part of the challenge. A high-quality furnace must ensure that temperature is uniform along the sample and that it can follow complex thermal profiles over time.

Single-Zone vs. Multi-Zone Control

A simple furnace may have a single heated section, or zone. This is effective for small samples or when minor temperature variation along the tube is acceptable.

More advanced furnaces feature multi-zone control. The furnace tube is divided into several separately heated and controlled areas, each with its own thermocouple and heating element set. This allows the system to compensate for heat loss at the ends of the tube, ensuring a highly uniform temperature profile along a much greater length.

Programmable Ramping and Cooling

Modern controllers are fully programmable. This allows users to define not just a target temperature but a complete thermal cycle.

You can specify the ramp rate (how quickly the furnace heats up), the dwell time (how long it holds at a specific temperature), and even control the cooling rate. This is critical for processes that are sensitive to thermal shock or require specific heat treatments.

The Role of the Furnace Tube

The tube itself is a critical component that dictates the furnace's capabilities. The material must be chosen based on the desired temperature.

A quartz tube is suitable for temperatures up to approximately 1200°C. For higher temperatures, up to 1700°C or more, a high-purity alumina tube is required due to its superior thermal resistance.

Understanding the Trade-offs and Safety

While powerful, these furnaces require an understanding of their limitations and operational hazards to ensure safe and effective use.

Over-Temperature Protection

A crucial safety feature is over-temperature protection. This is an independent safety circuit with its own sensor that will shut the furnace down if it detects a temperature exceeding a predefined safety limit. This protects the furnace, the lab, and the sample in the event of a primary control system failure.

Gas Environment Control

Many processes require a specific atmosphere. Tube furnaces often include gas purge capabilities, allowing an inert gas like argon or nitrogen to be flowed through the tube. This prevents oxidation of the sample at high temperatures.

Essential Operational Safety

Safe operation is non-negotiable. Only trained personnel wearing appropriate protective gear, such as heat-resistant gloves and safety goggles, should operate the furnace. The area must be well-ventilated, and materials that could release moisture or harmful gases when heated should be strictly avoided.

How to Apply This to Your Process

Your specific application will determine which features are most important for achieving your desired outcome.

- If your primary focus is reaching the highest possible temperatures: Prioritize a furnace with high-purity alumina tubes and robust heating elements designed for extreme heat.

- If your primary focus is temperature uniformity across a large sample: A multi-zone control system is essential for minimizing thermal gradients along the tube.

- If your primary focus is process repeatability and complex heat treatments: A fully programmable PID controller with precise ramp, dwell, and cooling functions is your most critical feature.

Understanding this control system empowers you to move beyond simple heating and achieve truly precise and repeatable thermal processing.

Summary Table:

| Component | Role in Temperature Control |

|---|---|

| Thermocouple | Measures internal temperature and sends data to the controller |

| PID Controller | Compares actual temperature to setpoint and adjusts power |

| Heating Elements | Generate heat based on controller signals to maintain stability |

| Multi-Zone Control | Ensures uniform temperature along the tube for larger samples |

| Programmable Features | Allows ramping, dwelling, and cooling for complex thermal cycles |

Ready to enhance your lab's thermal processing with precision and reliability? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to meet your unique experimental requirements. Contact us today to discuss how our furnaces can deliver superior temperature control and efficiency for your applications!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab