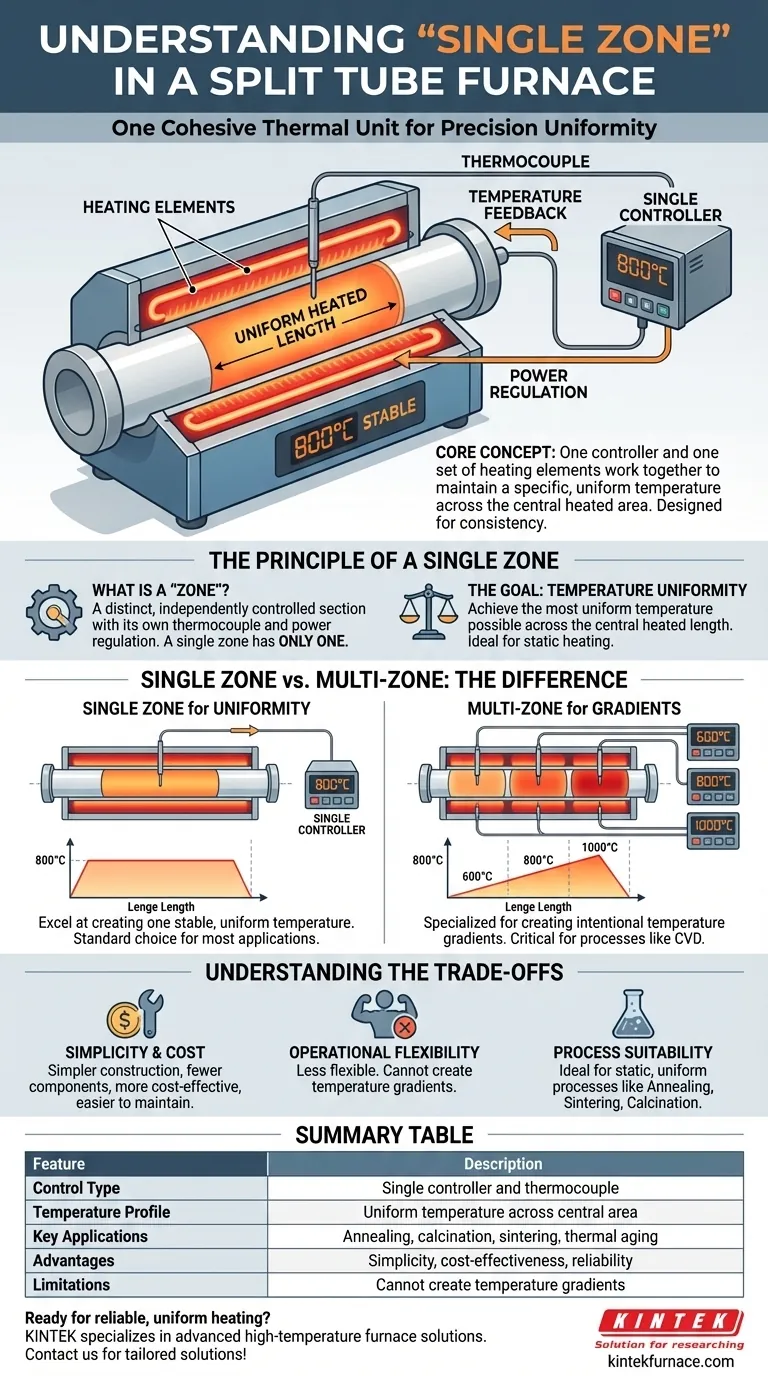

In the context of a split tube furnace, the term 'single zone' signifies that the entire heated length of the furnace operates as one cohesive thermal unit. This means a single controller and a single set of heating elements work together to create and maintain a specific, uniform temperature across the central heated area.

The core concept is control and uniformity. A single-zone furnace is designed for one task: to hold a sample at a stable, consistent temperature throughout its processing chamber. Its strength lies in its simplicity and reliability for uniform heating applications.

The Principle of a Single Zone Furnace

What is a "Zone"?

A zone is a distinct section of the furnace's heating chamber that is independently controlled. It has its own thermocouple for temperature measurement and its own power regulation for the heating elements.

In a single-zone furnace, there is only one such system. The controller reads the temperature from one point (typically the center) and adjusts the power to all heating elements simultaneously to maintain the setpoint.

The Goal: Temperature Uniformity

The primary engineering goal of a single-zone design is to achieve the most uniform temperature possible across a specified length in the center of the tube. This central area is known as the uniform heated length.

Manufacturers use specific winding techniques and high-quality insulation to minimize temperature drop-off toward the ends of the furnace, ensuring your sample experiences a consistent thermal environment.

How It Works in Practice

Imagine you are annealing a material sample. You place it in the center of the furnace tube, program the controller to 800°C, and start the process.

The controller will energize the heating elements. The single thermocouple will continuously report the temperature back to the controller, which then modulates power to prevent overshooting or undershooting the 800°C target, ensuring the sample is heated evenly.

Single Zone vs. Multi-Zone: Understanding the Difference

The alternative to a single-zone furnace is a multi-zone furnace, which typically has two, three, or even five independent zones. Understanding this distinction clarifies the purpose of a single-zone design.

Single-Zone for Uniformity

As established, a single-zone furnace excels at creating one stable, uniform temperature. It is the standard choice for the majority of thermal processing applications.

Multi-Zone for Gradients

A multi-zone furnace is a specialized tool designed to create a temperature gradient, where different parts of the furnace tube are intentionally held at different temperatures. Each zone has its own controller and thermocouple.

This is critical for advanced processes like Chemical Vapor Deposition (CVD) or certain types of crystal growth, where reactants must be heated to different temperatures as they flow through the tube.

Understanding the Trade-offs

Choosing between a single-zone and multi-zone furnace involves clear trade-offs in cost, complexity, and capability.

Simplicity and Cost

Single-zone furnaces are simpler in construction and operation. They have fewer components (one controller, fewer wiring circuits), making them significantly more cost-effective and generally easier to program and maintain.

Operational Flexibility

A single-zone furnace is less flexible. It cannot create a temperature gradient. If your experimental needs change and require a gradient, a single-zone furnace cannot be adapted for the task.

Process Suitability

The single-zone design is ideal for static, uniform heating processes. This includes most applications for annealing, calcination, sintering, and thermal aging. It is a robust and reliable workhorse for these tasks.

Multi-zone furnaces are required for dynamic processes that rely on a precisely controlled temperature profile along the length of the tube.

Making the Right Choice for Your Goal

The decision hinges entirely on the thermal process you need to perform.

- If your primary focus is uniform heating: A single-zone furnace is the correct, most efficient, and most cost-effective choice for applications like annealing, purifying, or sintering materials.

- If your primary focus is creating a temperature gradient: You must use a multi-zone furnace for processes like chemical vapor deposition (CVD) or directional solidification.

Ultimately, a single-zone furnace is the foundational tool for creating a stable and uniform thermal environment.

Summary Table:

| Feature | Description |

|---|---|

| Control Type | Single controller and thermocouple for entire heated length |

| Temperature Profile | Uniform temperature across central heated area |

| Key Applications | Annealing, calcination, sintering, thermal aging |

| Advantages | Simplicity, cost-effectiveness, reliability |

| Limitations | Cannot create temperature gradients |

Ready to enhance your lab's thermal processing with reliable, uniform heating? KINTEK specializes in advanced high-temperature furnace solutions, including single-zone split tube furnaces, designed for precision and durability. Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, with strong deep customization to meet your unique experimental needs. Contact us today to discuss how our tailored solutions can optimize your annealing, sintering, and other thermal processes for superior results!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- How do vertical tube furnaces comply with environmental standards? A Guide to Clean, Efficient Operation