At its core, a tube furnace is a high-precision heating device designed to create an exceptionally uniform temperature environment within a cylindrical chamber. Samples are placed inside this central work tube, which is then heated externally by elements positioned to ensure consistent heat distribution along its length. This design is fundamental for scientific experiments and industrial processes where precise thermal control is non-negotiable.

A tube furnace's defining characteristic is not merely its ability to reach high temperatures, but its specialized design—a cylindrical heating chamber—which is engineered specifically to minimize temperature variations and ensure uniform heat treatment for the sample within.

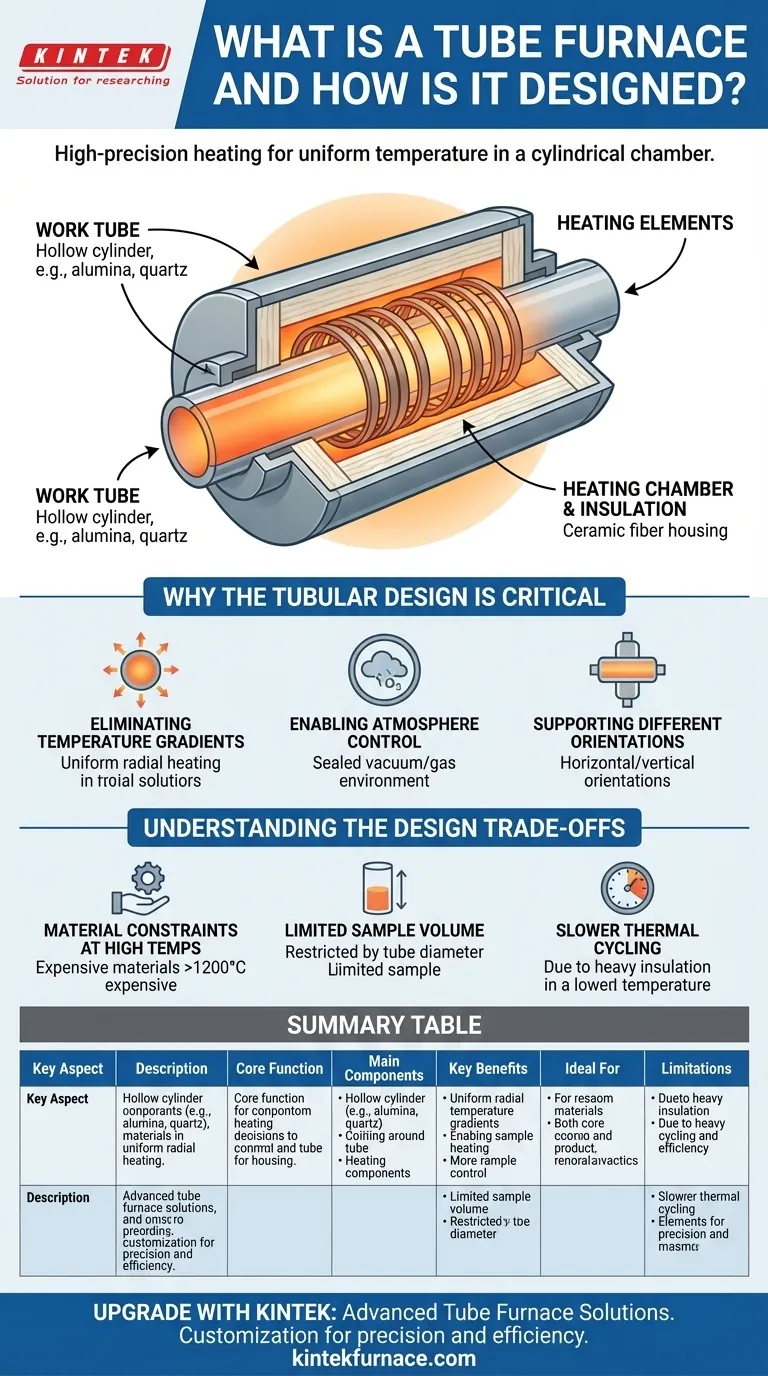

The Core Components of a Tube Furnace

To understand how a tube furnace achieves its precision, we must look at its key components, which work in concert to deliver stable and uniform heat.

The Work Tube

The work tube is the central vessel that contains the sample. It is a hollow cylinder typically made from highly heat-resistant materials like high-purity alumina, quartz, or specialized metal alloys. The choice of material depends on the required maximum temperature and chemical compatibility with the sample and any process gases.

The Heating Elements

Heating is provided by electric resistance elements, such as coils or ribbons, that are positioned around the outside of the work tube. Their precise placement is critical. They are often embedded within the furnace's insulating material to ensure heat radiates evenly onto the tube's entire surface, which is the key to achieving temperature uniformity.

The Heating Chamber and Insulation

The work tube and heating elements are housed within a heating chamber. This chamber is typically formed from high-temperature ceramic fiber insulation, which can be a single solid cylinder or two semi-cylindrical halves that close together. This robust insulation minimizes heat loss to the exterior and helps maintain a stable internal temperature.

Why the Tubular Design Is Critical

The cylindrical geometry of a tube furnace is a deliberate engineering choice driven by the need for consistency and control. It is fundamentally different from a simple box furnace.

Eliminating Temperature Gradients

By arranging heating elements symmetrically around a tube, the design ensures the sample is heated uniformly from all radial directions. This geometry drastically reduces temperature gradients along the heated length, preventing hot or cold spots that could compromise an experiment or material treatment process.

Enabling Atmosphere Control

The tubular shape is ideal for creating a sealed environment. By capping the ends of the work tube, operators can heat samples in a vacuum or introduce specific process gases. This controlled atmosphere is essential for applications like material synthesis, purification, or preventing oxidation during heat treatment.

Supporting Different Orientations

While many tube furnaces are horizontal, some applications benefit from a vertical orientation. For example, a vertical design is used to create a fluidized bed, where gas flowing upward through the tube suspends solid particles for efficient combustion or reaction.

Understanding the Design Trade-offs

While highly effective, the design of a tube furnace involves inherent compromises that make it ideal for some tasks but less suitable for others.

Material Constraints at High Temperatures

Achieving very high temperatures (above 1200°C) places extreme demands on materials. The work tube and heating elements must be made from expensive, high-performance ceramics or exotic metal alloys, increasing the furnace's cost and operational complexity.

Limited Sample Volume

The primary limitation of a tube furnace is its sample capacity, which is restricted by the inner diameter of the work tube. This design is optimized for precision over volume, making it unsuitable for heating large or bulky items.

Slower Thermal Cycling

The same heavy insulation and ceramic mass that provide excellent temperature stability also retain a great deal of heat. Consequently, tube furnaces typically have slower heat-up and cool-down times compared to less insulated systems, which can be a drawback for high-throughput applications.

Making the Right Choice for Your Goal

The decision to use a tube furnace should be based on the specific requirements of your process.

- If your primary focus is ultimate temperature uniformity for sensitive research or material processing: A tube furnace is the superior choice due to its purpose-built cylindrical heating geometry.

- If your primary focus is heat treating large or irregularly shaped objects: A box or muffle furnace provides a larger chamber and may be a more practical and cost-effective solution.

- If your primary focus is creating specific atmospheric conditions (vacuum or gas): The sealed environment of a tube furnace makes it the standard and most reliable tool for the job.

Understanding that a tube furnace is a specialized instrument for precision allows you to leverage its unique strengths for the most demanding thermal applications.

Summary Table:

| Key Aspect | Description |

|---|---|

| Core Function | High-precision heating with uniform temperature in a cylindrical chamber |

| Main Components | Work tube, heating elements, insulation chamber |

| Key Benefits | Eliminates temperature gradients, enables atmosphere control, supports various orientations |

| Ideal For | Sensitive research, material synthesis, vacuum/gas processes |

| Limitations | Limited sample volume, slower thermal cycling, higher cost for high temperatures |

Upgrade your laboratory with KINTEK's advanced tube furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with high-temperature furnaces like Tube Furnaces, Muffle Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs. Contact us today to discuss how our tailored solutions can enhance your precision heating and boost efficiency!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety