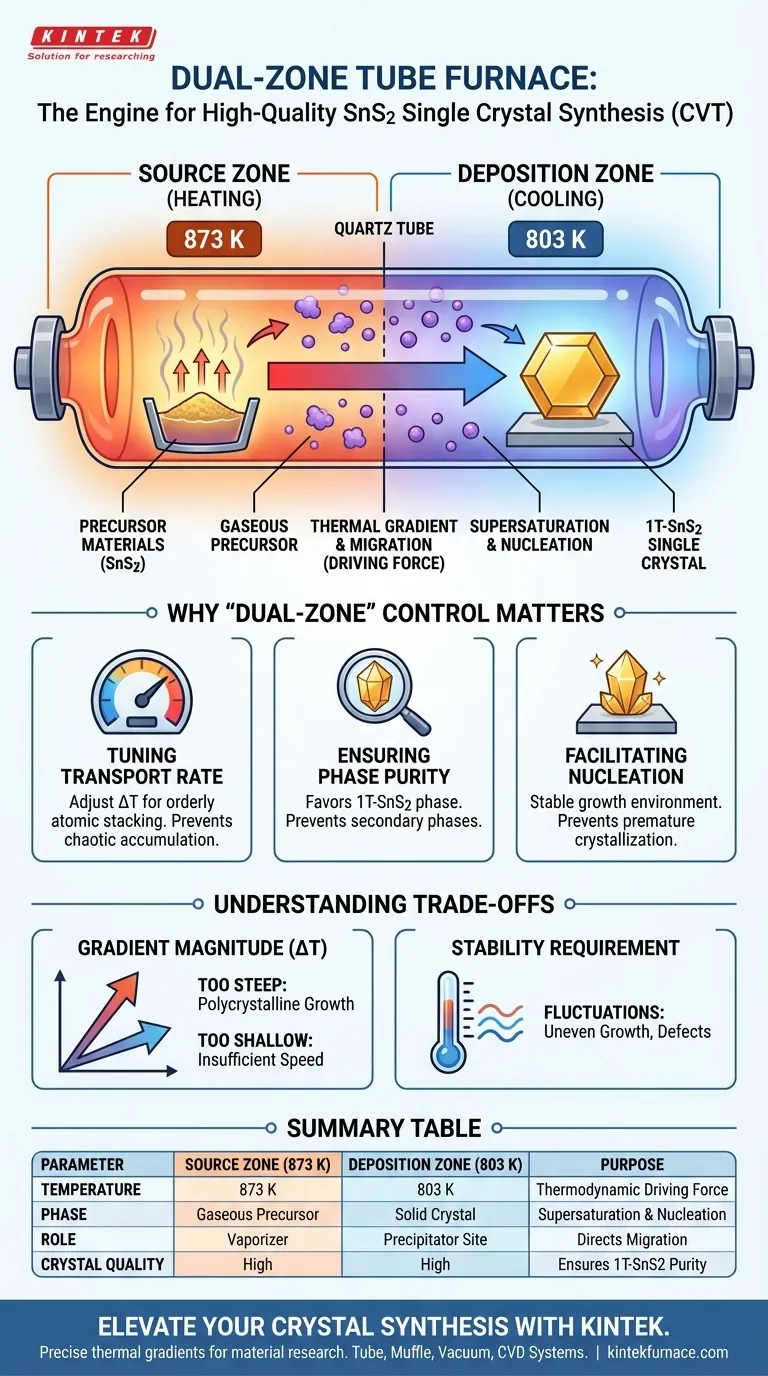

The primary role of a dual-temperature zone tube furnace in the synthesis of SnS2 single crystals is to establish and maintain a precise thermal gradient between a source zone and a deposition zone.

By independently heating the source material to 873 K and the deposition area to 803 K, the furnace creates a thermodynamic driving force. This compels the gaseous precursors to migrate from the high-temperature region to the lower-temperature region, resulting in the supersaturation necessary for the controlled nucleation and growth of high-quality 1T-SnS2 single crystals.

The Core Mechanism A dual-zone furnace does not merely heat materials; it engineers a "transport highway" using temperature differences. This gradient controls the speed at which vaporized materials travel and settle, serving as the critical variable that determines whether you produce a high-quality single crystal or a disordered powder.

The Mechanics of Chemical Vapor Transport (CVT)

To understand the furnace's role, one must look beyond simple heating and examine how temperature differentials drive physical movement and phase changes.

Establishing the Thermal Gradient

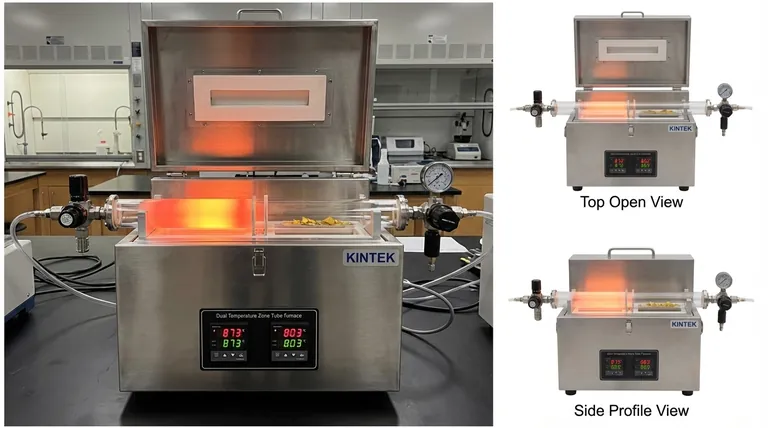

The defining feature of this equipment is its ability to maintain two distinct temperature profiles simultaneously within the same tube.

For SnS2 synthesis, the furnace maintains the source zone (where the raw material sits) at approximately 873 K.

Simultaneously, it holds the deposition zone (where the crystal grows) at a cooler 803 K.

The Driving Force for Migration

This specific temperature difference ($\Delta T$) is the engine of the CVT process.

At the higher temperature (873 K), the precursor materials react with a transport agent and enter a gaseous phase.

Because gas moves toward equilibrium, the vapor naturally diffuses toward the cooler end of the tube. Without this gradient, the vapor would remain stagnant, and no net transport would occur.

Achieving Supersaturation

As the hot vapor reaches the cooler deposition zone (803 K), it can no longer hold the same amount of material in the gas phase.

This cooling triggers supersaturation, forcing the material to precipitate out of the vapor.

This controlled precipitation allows the atoms to arrange themselves systematically, forming the specific lattice structure of 1T-SnS2 single crystals.

Why "Dual-Zone" Control Matters for Quality

The "dual" aspect of the furnace provides a level of control that a single-zone furnace cannot achieve, directly impacting the crystallinity and purity of the final product.

Tuning the Transport Rate

The quality of a single crystal is heavily dependent on how fast it grows.

By independently adjusting the two zones, you can fine-tune the $\Delta T$.

A precise gradient ensures the material is transported at a rate that allows for orderly atomic stacking, preventing rapid, chaotic accumulation.

Ensuring Phase Purity

SnS2 can exist in different structural phases or polytypes.

The primary reference indicates that the specific thermal environment (873 K to 803 K) favors the formation of the 1T-SnS2 phase.

Precise temperature control prevents thermal fluctuations that could lead to the formation of secondary phases or impurities.

Facilitating Nucleation

Crystal growth begins with nucleation—the formation of the first tiny crystal seed.

The dual-zone setup allows for a stable environment where nucleation occurs only in the specific growth zone.

This prevents premature crystallization in the middle of the tube, ensuring the final yield is concentrated and retrievable.

Understanding the Trade-offs

While a dual-zone furnace enables high-quality synthesis, it requires careful calibration. Understanding the limitations is essential for success.

Sensitivity to Gradient Magnitude

A larger temperature difference ($\Delta T$) increases the transport rate, but this is not always beneficial.

If the gradient is too steep, the transport becomes too fast, leading to polycrystalline growth or structural defects rather than a single crystal.

Conversely, if the gradient is too shallow, the transport speed may be insufficient to grow crystals of a usable size within a reasonable timeframe.

The Stability Requirement

The furnace must possess high thermal stability to maintain the setpoints (873 K / 803 K) without fluctuation.

Even minor oscillations in temperature can disrupt the supersaturation point, causing layers of the crystal to grow unevenly or inducing defects in the lattice structure.

Making the Right Choice for Your Goal

The dual-zone tube furnace is a precision tool. How you configure it depends on your specific experimental objectives for SnS2 synthesis.

- If your primary focus is Crystal Quality (Phas Purity): Strictly adhere to the reference gradient (Source: 873 K / Deposition: 803 K) to ensure the thermodynamic conditions favor the 1T-SnS2 lattice structure.

- If your primary focus is Growth Rate: Experiment with slightly increasing the source temperature to raise the vapor pressure, but monitor closely for the onset of polycrystalline defects.

- If your primary focus is Defect Reduction: Prioritize thermal stability over speed; ensure your furnace is calibrated to hold the temperature transition rate steady (e.g., preventing shock during heating/cooling).

Ultimately, the dual-temperature zone furnace transforms temperature into a physical force, using a controlled gradient to guide atoms from a chaotic vapor into a perfect crystalline order.

Summary Table:

| Parameter | Source Zone (Heating) | Deposition Zone (Cooling) | Purpose |

|---|---|---|---|

| Temperature | 873 K | 803 K | Creates thermodynamic driving force |

| Phase | Gaseous Precursor | Solid Crystal | Facilitates supersaturation and nucleation |

| Role | Vaporizes raw material | Precipitator site | Directs migration of gaseous atoms |

| Crystal Quality | High | High | Ensures 1T-SnS2 phase purity |

Elevate Your Crystal Synthesis with KINTEK

Precise thermal gradients are the difference between a disordered powder and a high-quality single crystal. KINTEK provides industry-leading Tube, Muffle, Vacuum, and CVD systems, all engineered for the rigorous stability required in Chemical Vapor Transport (CVT) and material research.

Why choose KINTEK?

- Expert R&D: Our furnaces are designed for precise temperature uniformity and stability.

- Fully Customizable: Tailor zone lengths and thermal profiles to your specific SnS2 or 2D material needs.

- Proven Reliability: Trusted by global labs for high-temperature manufacturing.

Contact our technical experts today to find the perfect furnace solution for your unique research requirements!

Visual Guide

References

- S. De Stefano, Antonio Di Bartolomeo. Neuromorphic Photoresponse in Ultrathin SnS<sub>2</sub>-Based Field Effect Transistor. DOI: 10.1021/acsami.5c11651

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1400℃ Muffle Oven Furnace for Laboratory

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- What are some common applications of vertical tube furnaces? Unlock Precision in High-Temp Processes

- Why are quartz or alumina tubes used in tube furnaces? Key Benefits for High-Temp Processes

- What are the advantages of tube furnaces for certain applications? Unlock Precise Atmosphere and Temperature Control

- Why is a vertical tube furnace preferred for quenching tests? Achieve Rapid, Repeatable Cooling for Accurate Results

- What is the technical significance of the high-temperature environment provided by a tube furnace in the synthesis of Fe3O4@Fe-AC?

- How does a dual-temperature zone tube furnace control crystal quality? Master PVT for Organic Single Crystals

- How do vertical tube furnaces contribute to advancements in material science and industrial production? Unlock Precision in Material Innovation

- What function does a tube furnace serve in the PVT growth of J-aggregate molecular crystals? Mastery of Thermal Control