In short, a vertical tube furnace is preferred for quenching tests because its orientation uses gravity to achieve an extremely rapid and repeatable transfer of the sample from the hot zone directly into the quenching medium below. This speed is critical for accurately "freezing" a material's high-temperature microstructure, which is the entire point of a quenching experiment. While any tube furnace provides excellent temperature and atmosphere control, the vertical setup uniquely solves the challenge of transfer time.

Quenching is a process defined by speed. The vertical tube furnace's primary advantage is not just its heating capability, but its ability to facilitate a near-instantaneous, gravity-assisted drop into a quench bath, minimizing variables and ensuring the most accurate and repeatable test results.

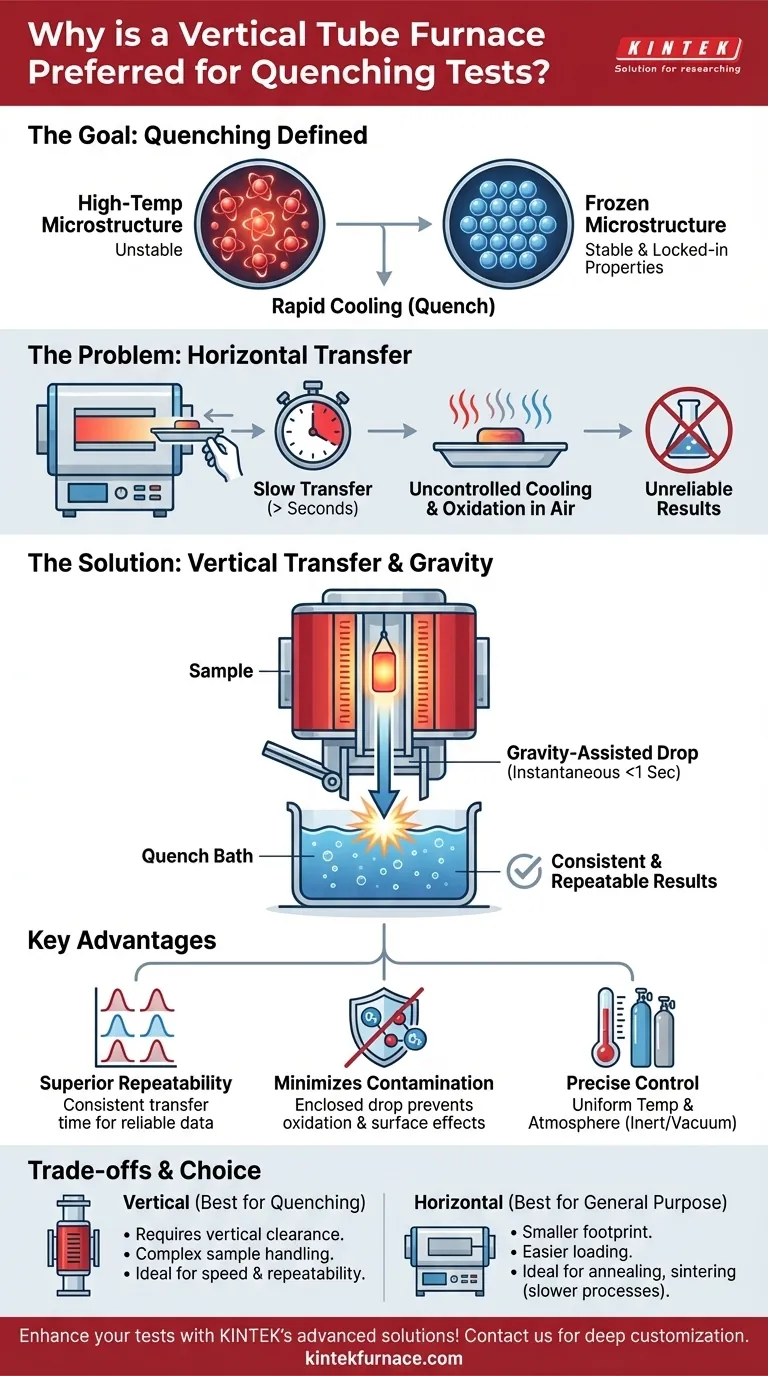

Why Transfer Speed Defines the Quenching Process

To understand the preference for a vertical design, we must first understand the core goal of quenching.

The Purpose of a Quench

Quenching is a heat treatment process where a material is rapidly cooled from a high temperature to lock in a specific microstructure. This structure, which is only stable at high heat, dictates the material's final mechanical properties like hardness and strength.

The success of the quench hinges on cooling the material so quickly that the atoms don't have time to rearrange into their normal, lower-temperature state.

Where a Slow Transfer Fails

If the transfer from the furnace to the quenching liquid (like water, oil, or polymer) is too slow, the sample begins to cool in the open air.

Even a delay of a few seconds is enough for the material's microstructure to start changing before it ever hits the liquid. This uncontrolled cooling introduces a massive variable, rendering the test results unreliable and not truly representative of the intended quench.

How the Vertical Design Solves the Transfer Problem

The vertical furnace configuration is a direct and elegant solution to the speed requirement. It aligns the furnace design with the physical demands of the process.

Leveraging Gravity for Instantaneous Transfer

In a vertical setup, the sample is suspended in the center of the uniform hot zone. A quench tank is placed directly beneath the furnace's lower opening.

When ready, a simple release mechanism allows the sample to drop directly into the quench bath. This transfer is powered by gravity, making it nearly instantaneous—often taking a fraction of a second. This eliminates the variable of uncontrolled cooling in ambient air.

Superior Repeatability and Control

Because the drop is governed by gravity, the transfer time is exceptionally consistent from one test to the next. This high degree of repeatability is essential for reliable scientific data and quality control.

In contrast, manually transferring a sample from a horizontal furnace involves pulling it out, moving it across, and then lowering it into a bath. This process is slower, operator-dependent, and far less repeatable.

Minimizing Atmospheric Contamination

The rapid, enclosed drop path of a vertical furnace also minimizes the sample's exposure to oxygen. This is critical for preventing oxidation on the material's surface, which can skew test results and affect surface properties.

Core Advantages Inherited from Tube Furnaces

Beyond the vertical orientation, these furnaces carry the fundamental benefits that make any tube furnace a powerful laboratory tool.

Exceptional Temperature Uniformity

Tube furnaces are known for their highly uniform temperature zones in the center of the tube. This ensures that the entire sample is at the correct, consistent temperature before the quench begins, which is a critical starting condition for the experiment.

Precise Atmosphere Control

The sealed nature of a tube furnace allows for precise control over the internal atmosphere. Experiments can be conducted in a vacuum or under specific inert gases (like argon or nitrogen) to prevent any unwanted chemical reactions during the heating phase.

Versatility and Simplicity

As a mature technology, tube furnaces are relatively simple to operate and can be configured for a wide array of sample sizes and materials. This makes them a versatile and essential tool in materials science labs.

Understanding the Trade-offs

While ideal for quenching, the vertical orientation has considerations that make it less suitable for other applications.

Structural and Space Requirements

A vertical furnace requires significant vertical clearance. The overall stack, including the furnace body and the quench tank below, can be quite tall, which may not fit in all laboratory spaces.

Sample Handling

Loading a sample and integrating a reliable release mechanism can be more complex in a vertical setup compared to simply sliding a sample boat into a horizontal tube.

Not a Universal Solution

For processes that do not require rapid cooling, such as slow annealing, sintering, or calcination, a horizontal tube furnace is often more practical. Its ease of loading and smaller footprint make it a more convenient choice when speed is not the primary concern.

Making the Right Choice for Your Process

Your choice of furnace orientation should be dictated entirely by the thermal process you need to execute.

- If your primary focus is rapid quenching: A vertical tube furnace is the unequivocal standard for achieving the speed, control, and repeatability necessary for accurate results.

- If your primary focus is general-purpose heat treatment: A horizontal tube furnace is often more practical, cost-effective, and easier to load for processes like annealing or drying.

- If your primary focus is high-throughput automation: Vertical furnaces are often easier to integrate with robotic loading and cassette systems, making them common in industrial settings like semiconductor manufacturing.

By selecting the equipment whose physical design complements the goals of your process, you ensure the highest possible fidelity in your results.

Summary Table:

| Aspect | Vertical Tube Furnace Advantage |

|---|---|

| Transfer Speed | Gravity-assisted drop for near-instantaneous quenching |

| Repeatability | Consistent transfer time for reliable data |

| Atmosphere Control | Sealed design prevents oxidation and contamination |

| Temperature Uniformity | Uniform hot zone ensures accurate heating |

| Best For | Quenching tests requiring rapid cooling |

Enhance your quenching tests with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide vertical tube furnaces and other products like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs for superior speed, repeatability, and performance. Contact us today to discuss how we can optimize your laboratory processes and deliver reliable results!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety