In essence, the primary advantages of a tube furnace are its exceptional atmospheric control and precise temperature management, making it indispensable for processes where the internal environment is as critical as the heat itself. Its contained, cylindrical design is uniquely suited for creating inert, reactive, or vacuum conditions that are difficult to achieve in other furnace types.

While many furnaces can get hot, a tube furnace excels by providing a highly controlled and isolated environment. Its core advantage lies in its ability to precisely manage the atmosphere around a sample, which is a non-negotiable requirement for many advanced material synthesis and treatment processes.

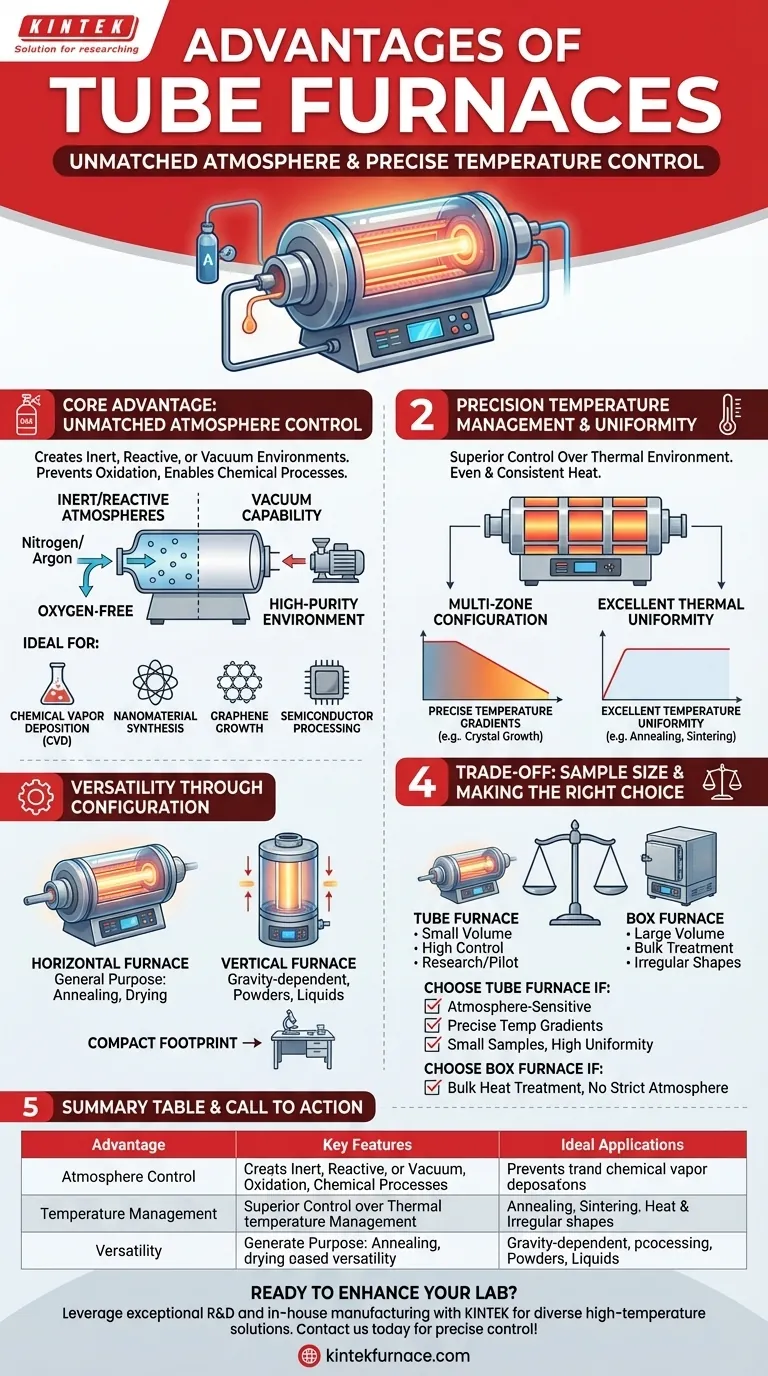

The Core Advantage: Unmatched Atmosphere Control

The most significant benefit of a tube furnace is the ability to create and maintain a specific gaseous environment. This is not just a feature; it is the central reason for its existence in many scientific and industrial applications.

Achieving Inert or Reactive Atmospheres

A tube furnace's design allows for the direct introduction of gas into the cylindrical chamber. By connecting a gas source and often a vacuum system, you can easily purge ambient air and introduce a protective, oxygen-free atmosphere using gases like nitrogen or argon.

This capability is critical for preventing oxidation or unwanted reactions during high-temperature processing. It also allows for the introduction of reactive gases required for specific chemical processes.

Why the Cylindrical Chamber Is Key

The simple, cylindrical geometry of the furnace tube is easy to seal effectively with flanges. This tight seal is paramount for maintaining a high-purity atmosphere or for pulling a vacuum, ensuring the integrity of the internal environment throughout the process.

Applications in Advanced Materials

This precise environmental control makes tube furnaces ideal for cutting-edge work. Applications like chemical vapor deposition (CVD), nanomaterial synthesis, graphene growth, and semiconductor processing all rely on the ability to manipulate the atmosphere with high fidelity.

Precision Temperature Management and Uniformity

Beyond atmosphere, tube furnaces offer superior control over the thermal environment. Heating elements typically surround the process tube, providing even and consistent heat to the sample.

Creating Specific Temperature Gradients

Many tube furnaces are available in multi-zone configurations. Each zone can be programmed and controlled independently, allowing you to create precise and stable temperature gradients along the length of the tube. This is vital for processes like crystal growth or certain types of catalyst testing.

Ensuring Excellent Thermal Uniformity

For processes like annealing and sintering, where the entire sample must experience the same temperature, the circumferential heating design of a tube furnace provides excellent thermal uniformity within the hot zone.

Features for Usability and Safety

Modern tube furnaces often include features that enhance safety and ease of use. A double-walled housing keeps the exterior surface cool to the touch, while a compact sliding design can allow for rapid cooling and easier loading or unloading of samples.

Versatility Through Configuration

Tube furnaces are not a one-size-fits-all solution. Their configuration can be adapted to the specific needs of a process, adding to their versatility.

Horizontal vs. Vertical Orientation

Horizontal furnaces are the most common type, used for general-purpose applications like annealing, purification, and drying.

Vertical furnaces are better suited for processes where gravity is a factor, such as thermal decomposition or when working with powders and liquids to avoid sample spillage.

Compact Footprint

By design, tube furnaces are ideal for labs with limited space. Their linear form factor occupies a relatively small footprint compared to bulkier box furnaces with similar temperature capabilities.

Understanding the Trade-off: Sample Size

While powerful, the primary limitation of a tube furnace is its processing volume. Its design inherently restricts the size and shape of the samples you can process.

The Limitation of Batch Volume

The diameter of the process tube directly limits the size of your workpiece. This makes tube furnaces best suited for research, pilot-scale production, or the processing of small, high-value components.

When a Box Furnace Is a Better Choice

If your process involves heat-treating large, bulky, or irregularly shaped items, or if you need to process a high volume of samples at once, a box furnace is the more appropriate tool. Its large, open chamber provides the capacity that a tube furnace lacks, though typically with less atmospheric control.

Making the Right Choice for Your Process

Ultimately, the decision depends on the specific requirements of your application.

- If your primary focus is atmosphere-sensitive processes (CVD, nanomaterials, oxygen-free annealing): A tube furnace is the definitive and often only choice due to its superior sealing and gas handling.

- If your primary focus is creating precise temperature gradients across a sample: A multi-zone tube furnace offers unparalleled control over the thermal profile.

- If your primary focus is processing small samples with high thermal uniformity: A single-zone tube furnace provides an excellent and efficient solution.

- If your primary focus is bulk heat treatment of large or numerous items without strict atmospheric needs: A box furnace will provide the necessary volume and is likely a more cost-effective option.

Choosing the correct furnace is about aligning the tool's core strengths with your most critical process variables.

Summary Table:

| Advantage | Key Features | Ideal Applications |

|---|---|---|

| Atmosphere Control | Inert/reactive gas handling, vacuum sealing | CVD, nanomaterial synthesis, semiconductor processing |

| Temperature Management | Multi-zone gradients, uniform heating | Annealing, sintering, crystal growth |

| Versatility | Horizontal/vertical orientation, compact design | Research, pilot-scale production, small sample processing |

Ready to enhance your lab's capabilities with a custom tube furnace? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how our tube furnaces can deliver precise atmosphere and temperature control for your specific applications!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab