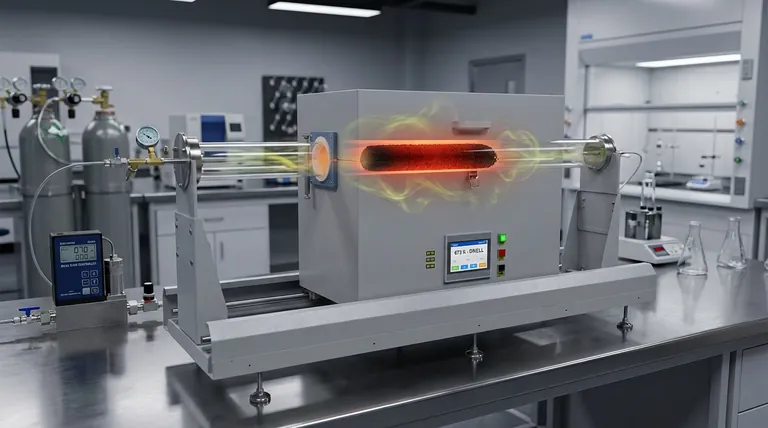

A high-temperature quartz tube furnace serves as the critical reaction chamber for the synthesis of sulfur and nitrogen co-doped activated carbon. Its primary function is to maintain a strictly controlled inert atmosphere (typically argon) while executing a precise heating profile (such as a constant hold at 673 K), which drives the decomposition of precursors like thioacetamide and embeds dopants into the carbon lattice.

Core Takeaway The furnace functions as an architectural tool rather than just a heat source. By strictly regulating the thermal and atmospheric environment, it prevents the oxidative destruction of the carbon support while enabling the precise embedding of heteroatoms to create specific coordination sites for stabilizing single-atom metals.

Mastering the Reaction Environment

Establishing an Inert Atmosphere

The most immediate function of the quartz tube furnace is to isolate the reactants from ambient air. By maintaining a continuous flow of inert gas, such as argon, the furnace creates an oxygen-free environment.

Without this exclusion of oxygen, the activated carbon substrate would undergo oxidative consumption (burn-off) at high temperatures. The inert atmosphere preserves the structural integrity of the carbon skeleton while the doping reactions occur.

Facilitating Precursor Decomposition

The furnace provides the specific thermal energy required to break down precursors. In your specific case, it facilitates the decomposition of thioacetamide mixed with activated carbon.

The controlled environment ensures that sulfur and nitrogen atoms released during this decomposition are not lost as volatile oxides. Instead, they are retained within the reaction zone, available to interact with the carbon surface.

Precision Thermal Regulation

Executing Precise Heating Curves

The furnace allows for the programming of exact temperature profiles, including ramp rates and dwell times. The primary reference highlights a constant temperature treatment at 673 K.

This specific thermal plateau is critical. It provides the activation energy necessary for the doping reaction to proceed without providing so much energy that the carbon structure collapses or the dopants volatilize completely.

Segmented Processing Capabilities

While the primary reaction occurs at high temperatures, the furnace's programmable nature allows for segmented heating. This can include lower-temperature stages to remove moisture or residual air before the main pyrolysis begins.

This ensures that the final high-temperature stage acts solely on the chemical transformation of the precursors and the carbon support, rather than wasting energy on evaporating solvents.

Engineering the Carbon Framework

Embedding Heteroatoms

The ultimate chemical function of the furnace is to drive the embedding of sulfur and nitrogen atoms into the graphitic carbon framework.

The heat promotes the breakage of C-C bonds and the formation of C-N and C-S bonds. This effectively "dopes" the material, altering its electronic properties and surface chemistry.

Constructing Coordination Environments

Beyond simple doping, the furnace enables the construction of specific coordination environments.

By controlling the temperature at 673 K, the process creates a stable arrangement of nitrogen and sulfur atoms. These arrangements serve as "anchors" capable of stabilizing single-atom metals, preventing them from aggregating and thereby enhancing catalytic performance.

Understanding the Trade-offs

Throughput vs. Control

Quartz tube furnaces offer exceptional control over atmosphere and temperature, but they typically have limited sample capacity compared to industrial rotary kilns. They are ideal for precision synthesis and research but can become a bottleneck if large-scale production is the immediate goal.

Sensitivity to Gas Flow Dynamics

The quality of the doping is highly sensitive to the flow rate of the inert gas.

- Too low: Oxygen may ingress, damaging the carbon support.

- Too high: Precursor vapors may be swept away before they have time to react with and embed into the carbon surface.

Optimizing Your Synthesis Strategy

To get the most out of your high-temperature quartz tube furnace, align your parameters with your specific goals:

- If your primary focus is stabilizing single-atom metals: Prioritize the exact maintenance of the 673 K constant temperature phase to ensure the correct coordination environment is formed between the carbon, sulfur, and nitrogen.

- If your primary focus is substrate integrity: Ensure a rigorous inert gas purge (argon) prior to ramping up the heat to prevent any oxidative loss of your activated carbon starting material.

The quartz tube furnace is not merely a heater; it is a precision instrument that dictates the chemical identity and catalytic potential of your final carbon support.

Summary Table:

| Function | Description | Key Benefit |

|---|---|---|

| Inert Atmosphere Control | Maintains oxygen-free argon flow | Prevents oxidation and burn-off of carbon framework |

| Thermal Decomposition | Precisely breaks down thioacetamide precursors | Releases S and N atoms for doping reactions |

| Precise Heating Curves | Executes programmable profiles (e.g., 673 K hold) | Ensures optimal activation energy for heteroatom embedding |

| Coordination Engineering | Constructs C-N and C-S bond environments | Creates stable anchors for single-atom metal catalysts |

Elevate Your Materials Synthesis with KINTEK

Precision is non-negotiable when engineering advanced catalytic supports. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your unique laboratory needs. Whether you are stabilizing single-atom metals or developing complex co-doped frameworks, our furnaces provide the rigorous atmospheric and thermal control your research demands.

Ready to optimize your synthesis? Contact KINTEK today to find the perfect high-temperature solution for your lab!

References

- Bin Li, Yunjie Ding. Water-participated mild oxidation of ethane to acetaldehyde. DOI: 10.1038/s41467-024-46884-7

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What critical experimental conditions does a tube furnace provide for carbonizing PI-COFs? Master Thermal Precision

- What critical reaction conditions are provided by a tube furnace for NiS2 synthesis? Achieve Pure Phase Results

- What role does a laboratory tube furnace play in STO thin film annealing? Unlock Neuromorphic Potential

- What is a rotary tube furnace? Achieve Superior Uniformity for Powders & Granules

- Why is it necessary to evacuate and seal quartz tubes for NiPS3 crystals? Master CVT Precision & Purity

- What is the role of a high-temperature Tube Furnace in copper alloy homogenization? Enhance Material Ductility

- Why are correct operating procedures important for laboratory tube furnaces? Ensure Safety and Accuracy in Your Experiments

- Why is a high-temperature tube furnace essential for PPAC activation? Precision Thermal Control for Superior Porosity