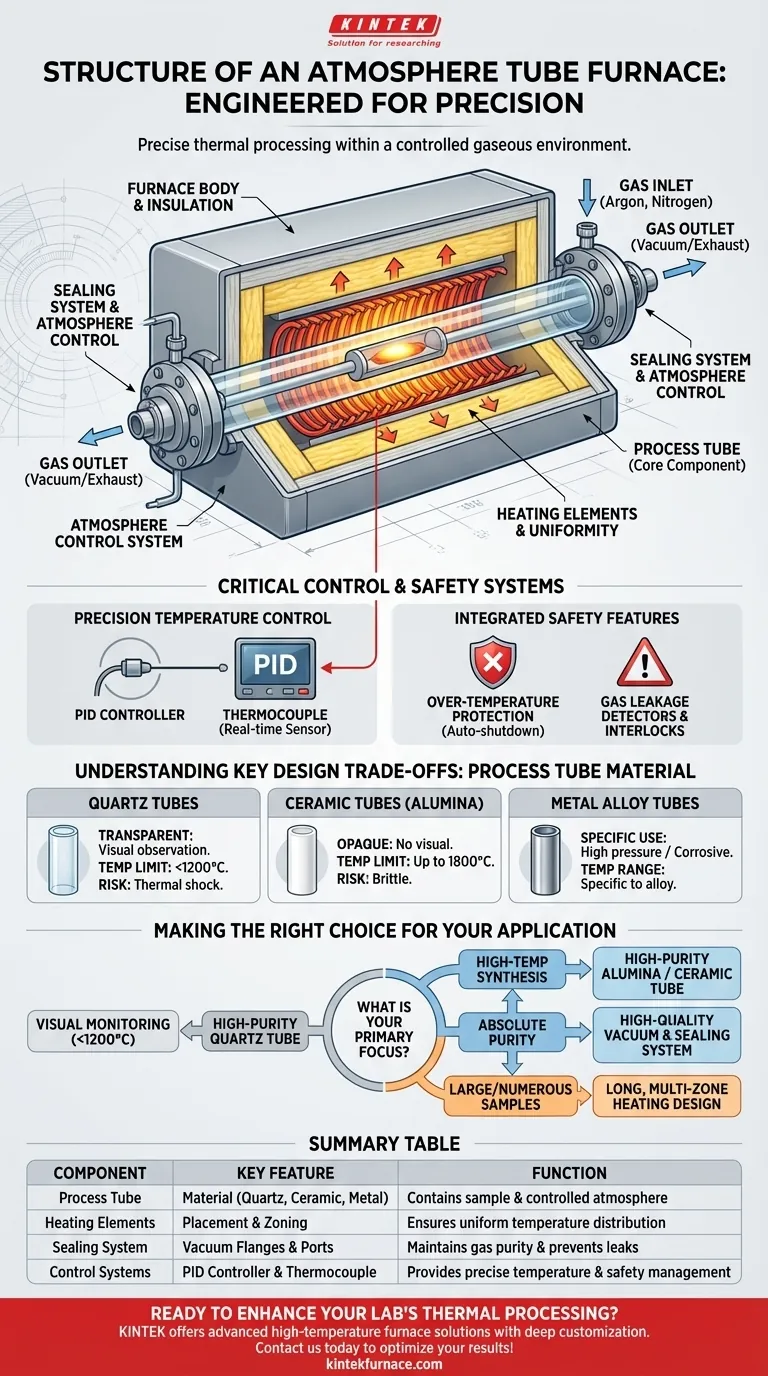

At its core, an atmosphere tube furnace is a system of integrated components designed for one primary purpose: precise thermal processing of materials within a tightly controlled gaseous environment. The main structural features include the furnace body, an internal process tube, specialized heating elements, and systems for controlling both temperature and atmosphere.

The structural design of an atmosphere tube furnace is not just a collection of parts, but an engineered solution. Every feature, from the material of the process tube to the placement of the heating elements, is a deliberate choice aimed at achieving uniform temperature and a pure, controlled atmosphere.

The Core Components of an Atmosphere Tube Furnace

The function of a tube furnace is defined by the interaction of its key structural components. Understanding each part reveals the engineering principles behind its operation.

The Furnace Body and Insulation

The furnace body is the external casing that houses all other components. It provides structural support and, crucially, contains layers of high-grade ceramic fiber insulation.

This insulation is critical for minimizing heat loss, which ensures energy efficiency and maintains a safe external temperature for operators.

The Process Tube: The Heart of the System

The process tube is the central component where the material sample is placed and heated. This sealed tube is what contains the controlled atmosphere.

The material of this tube is a defining design feature, chosen based on the required temperature and chemical environment.

The Sealing System and Atmosphere Control

To maintain a specific gas environment, the ends of the process tube must be sealed. This is typically achieved with vacuum flanges.

These flanges are equipped with ports that serve as gas inlets and outlets, allowing for purging with inert gases (like argon or nitrogen) or introducing reactive gases. This entire assembly forms the atmosphere control system.

Heating Elements and Uniformity

Heating is accomplished by electric heating elements, such as molybdenum disilicide (MoSi2) or silicon carbide (SiC) rods, which are positioned around the exterior of the process tube.

Their placement and grouping into zones are carefully designed to create a uniform temperature zone along a specific length of the tube, ensuring the entire sample is heated evenly.

Critical Control and Safety Systems

Beyond the physical structure, the furnace's reliability and safety depend on its electronic control and protection systems.

Precision Temperature Control

The temperature control system is the brain of the furnace. It uses a sensor, typically a thermocouple, placed near the process tube to measure the temperature in real-time.

This sensor feeds data to a PID (Proportional-Integral-Derivative) controller, which precisely adjusts the power sent to the heating elements to follow a programmed temperature profile.

Integrated Safety Features

Modern furnaces are designed with safety as a priority. A key feature is over-temperature protection, an independent system that shuts down the furnace if it exceeds a set safety limit.

Many models also include gas leakage detectors and safety interlocks that prevent operation under unsafe conditions, protecting both the user and the equipment.

Understanding Key Design Trade-offs

The choice of a furnace's structural features involves balancing performance, application, and cost. The process tube material is the most significant trade-off.

Quartz vs. Ceramic vs. Metal Tubes

Quartz tubes are transparent, allowing for direct visual observation of the process. However, they are generally limited to temperatures below 1200°C and can be susceptible to thermal shock.

Ceramic tubes (most often high-purity Alumina) can withstand much higher temperatures (up to 1800°C). Their drawback is that they are opaque and can be more brittle than quartz.

Metal alloy tubes are used for specific applications requiring high pressure or resistance to certain corrosive atmospheres where a ceramic tube might fail. Their temperature range and chemical compatibility are highly specific to the alloy used.

Making the Right Choice for Your Application

Your specific goal determines which structural features are most important for your work.

- If your primary focus is visual process monitoring below 1200°C: A furnace designed with a high-purity quartz tube is the correct choice.

- If your primary focus is high-temperature synthesis or sintering: You need a furnace built with a high-purity alumina or other ceramic process tube.

- If your primary focus is ensuring absolute purity for sensitive materials: Prioritize a furnace with a high-quality vacuum and sealing system to effectively purge oxygen.

- If your primary focus is processing large or numerous samples: Look for a furnace with a long, multi-zone heating element design for a larger uniform temperature zone.

By understanding how these structural features work together, you can confidently select and operate the right tool for your specific scientific or industrial goal.

Summary Table:

| Component | Key Feature | Function |

|---|---|---|

| Process Tube | Material (e.g., Quartz, Ceramic, Metal) | Contains sample and controlled atmosphere |

| Heating Elements | Placement and zoning | Ensures uniform temperature distribution |

| Sealing System | Vacuum flanges and ports | Maintains gas purity and prevents leaks |

| Control Systems | PID controller and thermocouple | Provides precise temperature and safety management |

Ready to enhance your lab's thermal processing? KINTEK offers advanced high-temperature furnace solutions, including Tube Furnaces, with deep customization to meet your unique experimental needs. Leveraging our exceptional R&D and in-house manufacturing, we ensure precise temperature control, uniform heating, and reliable atmosphere management for diverse laboratory applications. Contact us today to discuss how our products can optimize your results!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

People Also Ask

- What are some specific applications of atmosphere furnaces in the ceramics industry? Enhance Purity and Performance

- What are the primary inert gases used in vacuum furnaces? Optimize Your Heat Treatment Process

- How does the pressure range change under vacuum conditions in an atmosphere box furnace? Explore Key Shifts for Material Processing

- How do argon and nitrogen protect samples in vacuum furnaces? Optimize Your Thermal Process with the Right Gas

- What are the development prospects of atmosphere box furnaces in the aerospace industry? Unlock Advanced Material Processing for Aerospace Innovation