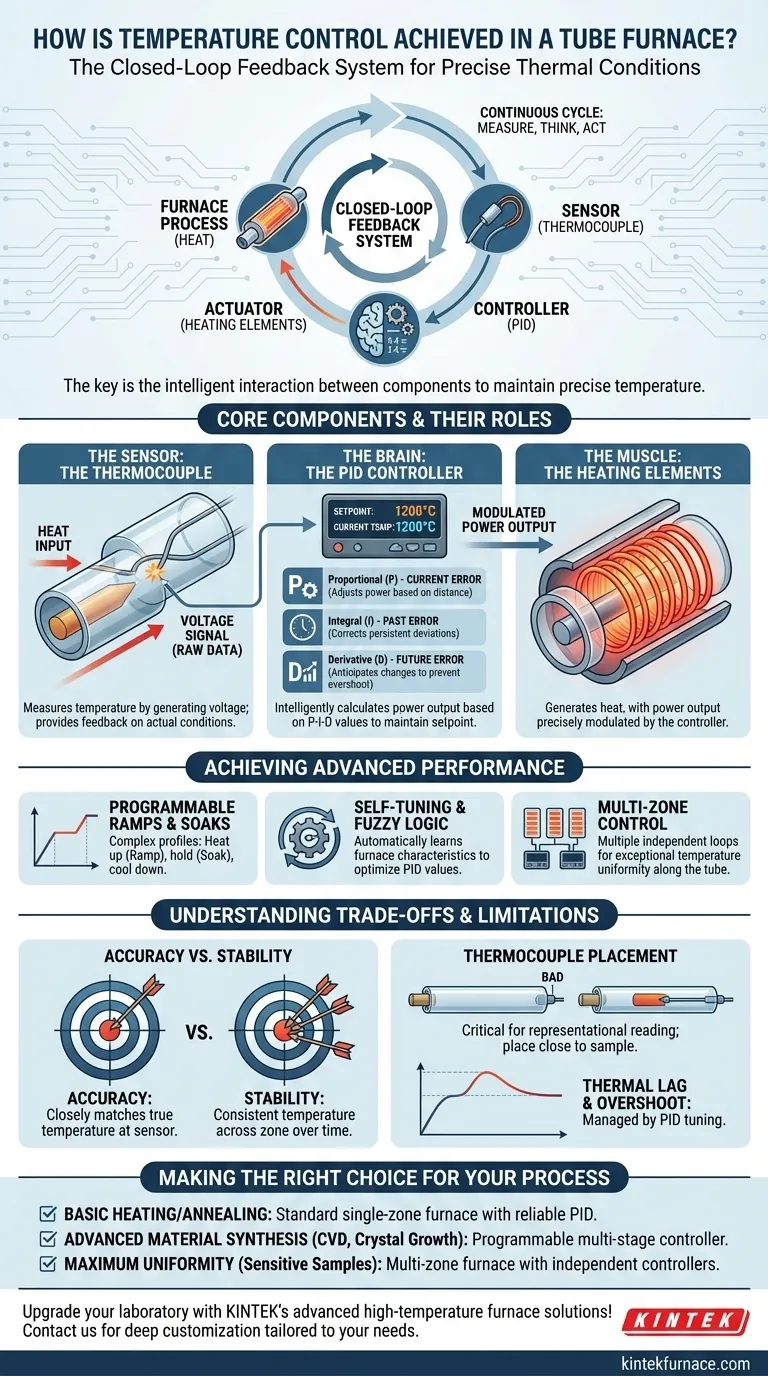

At its core, temperature control in a tube furnace is achieved through a closed-loop feedback system. A temperature sensor, typically a thermocouple, continuously measures the temperature inside the furnace and sends this data to a dedicated controller. The controller compares this real-time temperature to your desired setpoint and precisely adjusts the power sent to the heating elements to eliminate any difference.

The key is not a single component, but the intelligent interaction between them. A sensor measures, a controller thinks, and heating elements act, all working in a continuous cycle to maintain precise and stable thermal conditions for your process.

The Core Components of the Control System

To understand how a furnace achieves such high precision, you must first understand the three critical components working in concert. Each has a distinct and essential role in the feedback loop.

The Sensor: The Thermocouple

The thermocouple is the "eyes" of the system. It is a sensor made from two different metal wires joined at one end, which is placed inside the furnace tube to measure the temperature.

This junction generates a tiny voltage that changes predictably with temperature. This voltage signal is the raw data fed back to the controller, representing the actual conditions your sample is experiencing.

The Brain: The PID Controller

The PID (Proportional-Integral-Derivative) controller is the brain of the operation. It receives the voltage signal from the thermocouple, converts it into a temperature reading, and intelligently decides how to adjust the heating elements.

The term "PID" refers to the three mathematical calculations it performs to prevent overshooting the target temperature or oscillating around it:

- Proportional (P): This action is based on the current error. If the temperature is far from the setpoint, it applies a large amount of power. As it gets closer, it reduces power.

- Integral (I): This action looks at the past error. It corrects for small, persistent deviations, such as those caused by heat loss, ensuring the furnace reaches and holds the exact setpoint over time.

- Derivative (D): This action anticipates the future error. By monitoring the rate of temperature change, it slows down the heating as it approaches the setpoint to prevent overshooting, much like you'd ease off the gas when approaching a stoplight.

The Muscle: The Heating Elements

The heating elements are the components that actually generate the heat. The PID controller doesn't turn them on or off like a simple thermostat; instead, it modulates the power output sent to them.

By precisely adjusting the amount of electricity flowing through the elements, the controller can make minute corrections, ensuring the heat generated perfectly matches what is needed to maintain your target temperature.

How the System Achieves Advanced Performance

Beyond the basic PID loop, modern furnaces employ additional strategies to meet the demanding requirements of processes like chemical vapor deposition (CVD), nanomaterial synthesis, and wafer cleaning.

Programmable Ramps and Soaks

Many advanced controllers are "multi-stage intelligent program controllers." This means you can program a complex temperature profile over time.

For example, you can command the furnace to heat up at a specific rate (ramp), hold at a precise temperature for several hours (soak), and then cool down at a controlled rate. This is critical for processes that require careful thermal cycling.

Self-Tuning and Fuzzy Logic

To optimize performance, some controllers use self-tuning algorithms. The controller can run a test cycle to "learn" the furnace's unique thermal characteristics—how fast it heats up and cools down. It then uses this data to automatically calculate the optimal P, I, and D values for maximum stability.

Multi-Zone Control for Uniformity

A standard furnace has one set of heating elements and one thermocouple, creating a single heating zone. However, for longer tubes or processes requiring exceptional temperature uniformity, multi-zone furnaces are used.

These furnaces have several independent sets of heating elements and thermocouples along the length of the tube. Each zone is managed by its own control loop, allowing the system to compensate for heat loss at the ends of the tube and maintain a highly stable and uniform temperature across a larger area.

Understanding the Trade-offs

Achieving perfect temperature control involves navigating inherent physical and technical limitations. Understanding these is key to interpreting your results correctly.

Accuracy vs. Stability

These terms are often used interchangeably but mean different things.

- Accuracy refers to how closely the displayed temperature matches the true temperature at the thermocouple's tip (e.g., ±1°C).

- Stability (or Uniformity) refers to how consistently the temperature is maintained across the entire heated zone over time (e.g., ±5°C). A multi-zone furnace significantly improves stability.

Thermocouple Placement is Critical

The control system is only as good as the information it receives. The controller will hold a perfect temperature at the thermocouple's location. If your sample is located far from the thermocouple, its actual temperature may be different. For critical processes, placing the thermocouple as close to the sample as possible is essential.

Thermal Lag and Overshoot

A furnace has thermal mass, meaning it cannot change temperature instantly. This thermal lag is what a well-tuned PID controller is designed to manage. A poorly tuned system will either heat too aggressively and overshoot the setpoint, or it will be too timid and take an excessively long time to reach the target.

Making the Right Choice for Your Process

The level of temperature control you need is directly tied to the demands of your scientific or industrial process.

- If your primary focus is basic heating or annealing: A standard, single-zone furnace with a reliable PID controller is perfectly sufficient.

- If your primary focus is advanced material synthesis (like CVD or crystal growth): A programmable, multi-stage controller is non-negotiable for executing complex temperature profiles.

- If your primary focus is maximum temperature uniformity for sensitive samples: A multi-zone furnace with independent controllers is the superior choice to guarantee consistent conditions.

Understanding this control system empowers you to select the right equipment and optimize its settings to achieve repeatable, high-quality results.

Summary Table:

| Component | Role in Temperature Control |

|---|---|

| Thermocouple | Measures temperature and sends data to the controller |

| PID Controller | Adjusts power based on current, past, and future errors for stability |

| Heating Elements | Generate heat as modulated by the controller |

| Multi-Zone Control | Enhances uniformity across the furnace tube |

| Programmable Ramps/Soaks | Allows for complex temperature profiles over time |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable tube furnaces, muffle furnaces, and CVD/PECVD systems. Our strong deep customization capability ensures precise temperature control tailored to your unique experimental needs. Contact us today to discuss how our products can enhance your process efficiency and accuracy!

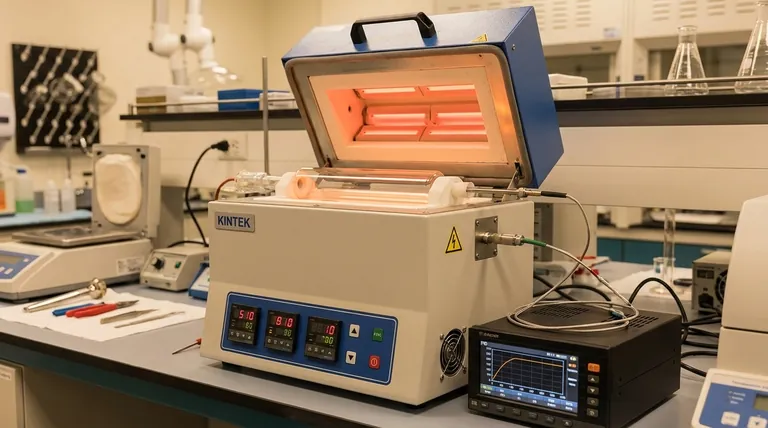

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- How does a laboratory tube furnace regulate the positioning of platinum (Pt) atoms? Mastering Atomic-Scale Engineering

- What is the design advantage of a split tube furnace? Unlock Easy Access for Complex Lab Setups

- What critical role does a laboratory tube furnace play in pBN-CTF synthesis? Master Molecular Engineering

- How does heating zone length impact tube furnace performance? Optimize Uniformity and Capacity

- What types of materials can be processed in a vacuum tube furnace? Unlock High-Purity Processing for Metals, Ceramics, and More

- What is the specific role of a tube furnace in the synthesis and carbon-encapsulation of NiMo alloys? Explained

- Why is a high-temperature tube furnace required for the preparation of barium ferrite? Achieve Optimal Magnetism

- What is the purpose of using a high-temperature tube furnace with an argon atmosphere during carbonization?