In geological and mineralogical research, a laboratory tube furnace serves as a miniature, controllable analog of the Earth's crust and mantle. It allows scientists to precisely simulate the extreme temperature and atmospheric conditions deep within the planet, enabling them to study how rocks and minerals melt, transform, and recrystallize over geological timescales in a controlled laboratory setting.

A laboratory tube furnace is not just a heating device; it is a critical tool for experimental petrology and mineralogy. It empowers researchers to move beyond observation of existing rocks and actively recreate the dynamic, high-temperature processes that form them.

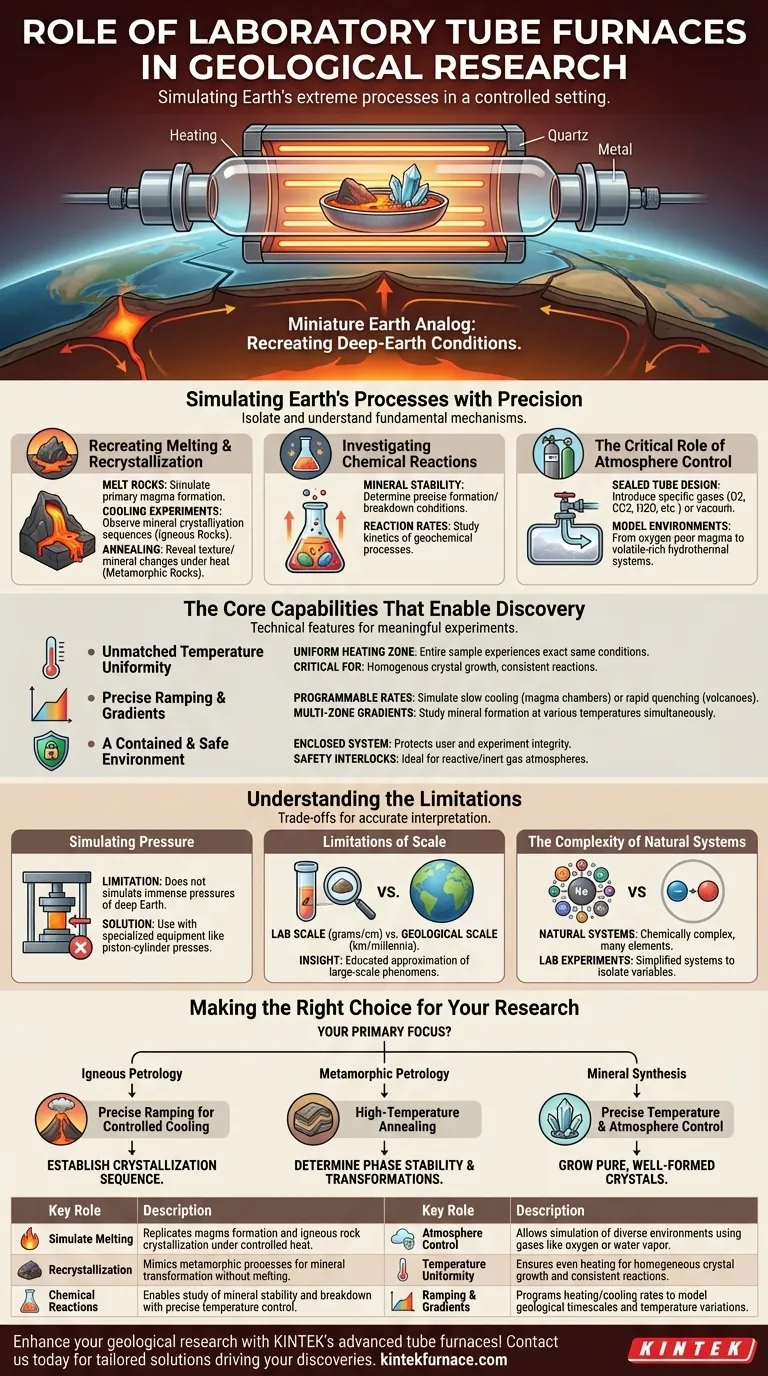

Simulating Earth's Processes with Precision

The primary role of a tube furnace in geology is to replicate conditions that are impossible to observe directly. By controlling key variables, researchers can isolate and understand the fundamental mechanisms of rock and mineral formation.

Recreating Melting and Recrystallization

Tube furnaces provide the high, uniform heat necessary to melt rock and mineral samples. This allows geologists to study the composition of primary magmas and observe how different minerals crystallize from a melt as it cools, mimicking the formation of igneous rocks.

Similarly, they can subject existing minerals to intense heat without melting them to simulate metamorphic processes. This helps reveal how rock textures and mineral assemblages change in response to burial and tectonic activity.

Investigating Chemical Reactions

Mineral stability and chemical reactions are highly dependent on temperature. A tube furnace offers the precise temperature control needed to determine the exact conditions under which a specific mineral will form, break down, or react with its environment.

The Critical Role of Atmosphere Control

The sealed tube design is crucial. It allows researchers to introduce specific gases (or create a vacuum) to simulate the diverse atmospheric conditions found within the Earth.

By controlling the presence of gases like oxygen, carbon dioxide, or water vapor, scientists can accurately model environments ranging from oxygen-poor magmatic chambers to volatile-rich hydrothermal systems, dramatically influencing which minerals form.

The Core Capabilities That Enable Discovery

A tube furnace is uniquely suited for geological research because of its core design features. These technical capabilities are what give researchers the control they need to run meaningful experiments.

Unmatched Temperature Uniformity

A key advantage is the ability to maintain a highly uniform temperature zone along the length of the processing tube. This ensures that the entire sample experiences the exact same conditions, which is critical for growing homogenous crystals or ensuring a reaction proceeds evenly.

Precise Ramping and Gradients

Advanced controllers allow geologists to program specific heating and cooling rates (ramping). This can simulate the slow cooling of a deep magma chamber or the rapid quenching of a volcanic eruption.

Some multi-zone furnaces can also create a stable temperature gradient, allowing researchers to study how different minerals form simultaneously at various temperatures from the same source material.

A Contained and Safe Environment

The enclosed nature of the tube furnace provides a safe, contained environment for high-temperature experiments. Safety interlocks and robust insulation protect both the user and the integrity of the experiment, especially when working with reactive or inert gas atmospheres.

Understanding the Limitations

While powerful, a tube furnace is a simulation tool with inherent trade-offs that are important to acknowledge for accurate scientific interpretation.

Simulating Pressure

A standard tube furnace excels at controlling temperature and atmosphere, but it does not simulate pressure. The immense pressures found deep within the Earth significantly impact mineral stability. For studies requiring both high temperature and high pressure, tube furnaces are often used in conjunction with other specialized equipment like piston-cylinder presses.

Limitations of Scale

Laboratory experiments operate on a scale of grams and centimeters, whereas geological processes occur on the scale of kilometers and millennia. The results provide critical insights into the underlying physics and chemistry but are an educated approximation of large-scale natural phenomena.

The Complexity of Natural Systems

Natural magmas and geological systems are chemically complex, often containing dozens of elements. Laboratory experiments typically simplify these systems to isolate variables. This is a scientific strength for understanding specific mechanisms but a limitation when applying results to a complex natural environment.

Making the Right Choice for Your Research

To leverage a tube furnace effectively, align its capabilities with your specific geological question.

- If your primary focus is igneous petrology: Use the furnace's precise temperature ramping for controlled cooling experiments to establish the crystallization sequence of minerals from a melt.

- If your primary focus is metamorphic petrology: Use the furnace for high-temperature annealing experiments to determine the phase stability and transformation points of key index minerals.

- If your primary focus is mineral synthesis: Use the combination of precise temperature and atmosphere control to grow pure, well-formed mineral crystals for subsequent analysis or characterization.

Ultimately, the laboratory tube furnace is an indispensable tool that allows geologists to test hypotheses and reveal the planet's hidden formative processes, one experiment at a time.

Summary Table:

| Key Role | Description |

|---|---|

| Simulate Melting | Replicates magma formation and igneous rock crystallization under controlled heat. |

| Recrystallization | Mimics metamorphic processes for mineral transformation without melting. |

| Chemical Reactions | Enables study of mineral stability and breakdown with precise temperature control. |

| Atmosphere Control | Allows simulation of diverse environments using gases like oxygen or water vapor. |

| Temperature Uniformity | Ensures even heating for homogeneous crystal growth and consistent reactions. |

| Ramping and Gradients | Programs heating/cooling rates to model geological timescales and temperature variations. |

Enhance your geological research with KINTEK's advanced tube furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature solutions like Tube Furnaces, Muffle Furnaces, and CVD/PECVD Systems. Our deep customization capability ensures precise alignment with your unique experimental needs, from igneous petrology to mineral synthesis. Contact us today to discover how our tailored furnace solutions can drive your discoveries forward!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- How do vertical tube furnaces comply with environmental standards? A Guide to Clean, Efficient Operation

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety