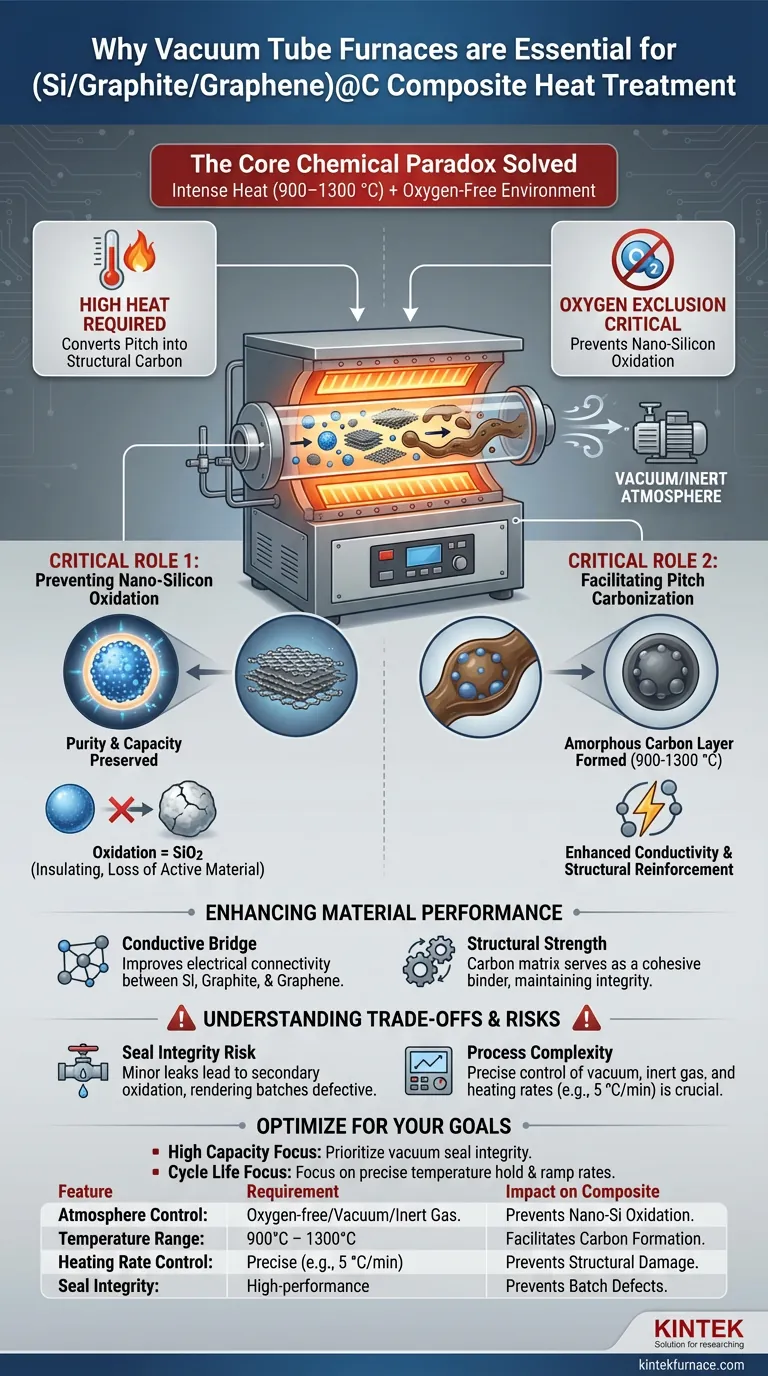

The primary necessity for using a vacuum tube furnace in processing (Si/graphite/graphene)@C composites is to create a strictly oxygen-free environment at high temperatures (typically around 1000 °C). This specific atmosphere allows for the chemical cracking and carbonization of pitch precursors into a conductive carbon layer while simultaneously preventing the catastrophic oxidation of highly reactive nano-silicon particles.

Core Takeaway The vacuum tube furnace solves a critical chemical paradox: it provides the intense heat required to convert pitch into structural carbon, yet strictly excludes the oxygen that would otherwise destroy the silicon's electrochemical capacity during that same heating process.

The Critical Role of the Vacuum Environment

Preventing Nano-Silicon Oxidation

The most sensitive component in this composite is the nano-silicon. Silicon is highly reactive to oxygen at elevated temperatures. Without a vacuum or strictly inert atmosphere, the high heat required for processing would cause the silicon to react with oxygen, forming silicon dioxide (SiO2).

This oxidation is detrimental because it creates an insulating layer and consumes the active silicon material. By maintaining a vacuum or inert gas flow, the furnace preserves the purity and theoretical capacity of the silicon, ensuring it remains electrochemically active.

Facilitating Pitch Carbonization

The composite utilizes a pitch precursor coated on the particle surfaces. To function effectively, this pitch must undergo cracking and carbonization.

This chemical transformation requires temperatures typically in the range of 900–1300 °C (often around 1000 °C). The vacuum tube furnace provides the precise thermal conditions necessary to decompose the pitch, stripping away non-carbon elements and leaving behind a robust carbon residue.

Enhancing Material Performance

Formation of the Amorphous Carbon Layer

The heat treatment process results in the formation of a uniform amorphous carbon layer around the silicon, graphite, and graphene particles.

This layer is not merely a byproduct; it is a functional component of the composite. It serves as a conductive bridge, significantly improving the electrical connectivity between the varying particle types (silicon, graphite, and graphene).

Structural Reinforcement

Beyond conductivity, the carbon layer generated in the furnace enhances the overall structural strength of the composite material.

During the carbonization process, the pitch serves as a binder that transforms into a hard carbon matrix. This creates a cohesive structure that helps accommodate volume changes and maintains mechanical integrity during use.

Understanding the Trade-offs

The Risk of Seal Integrity

The effectiveness of this process relies entirely on the isolation of the chamber. Even a minor leak in the tube furnace or a failure in the vacuum seal can introduce trace amounts of oxygen. At 1000 °C, even low partial pressures of oxygen can lead to the "secondary oxidation" of the silicon, rendering the batch defective.

Process Consistency vs. Complexity

While a vacuum tube furnace delivers high consistency and cleanliness, it introduces complexity regarding atmosphere control. The process often requires a balance between pulling a vacuum and introducing high-purity inert gas (like argon) to facilitate heat transfer and protect the carbon matrix. Precise control over heating rates (e.g., 5 °C/min) is often required to prevent structural damage during the rapid outgassing of the pitch.

Making the Right Choice for Your Goal

To maximize the quality of your (Si/graphite/graphene)@C material, align your furnace parameters with your specific performance targets:

- If your primary focus is high capacity: Prioritize the quality of the vacuum level and seal integrity to ensure absolute minimal oxidation of the nano-silicon.

- If your primary focus is cycle life and stability: Focus on the precision of the temperature hold times and ramp rates to ensure the amorphous carbon layer forms a uniform, structurally sound coating.

Success in this process depends not just on reaching high temperatures, but on the absolute exclusion of oxygen to preserve the active chemistry of the silicon.

Summary Table:

| Feature | Requirement | Impact on Composite Quality |

|---|---|---|

| Atmosphere Control | Oxygen-free / Vacuum / Inert Gas | Prevents nano-silicon oxidation and capacity loss |

| Temperature Range | 900°C – 1300°C | Facilitates pitch cracking and amorphous carbon formation |

| Heating Rate Control | Precise (e.g., 5 °C/min) | Prevents structural damage during pitch outgassing |

| Seal Integrity | High-performance vacuum seals | Prevents secondary oxidation and batch defects |

Elevate Your Material Research with KINTEK Precision

Don't let oxidation compromise your composite's electrochemical capacity. Backed by expert R&D and manufacturing, KINTEK offers high-performance Tube, Vacuum, and CVD systems designed to meet the rigorous demands of (Si/graphite/graphene)@C synthesis. Our customizable lab high-temp furnaces provide the absolute atmosphere control and thermal precision needed to ensure uniform carbonization and structural integrity.

Ready to optimize your heat treatment process? Contact us today to discuss your unique research needs and discover the KINTEK advantage.

Visual Guide

References

- Chengyuan Ni, Zhendong Tao. Effect of Graphene on the Performance of Silicon–Carbon Composite Anode Materials for Lithium-Ion Batteries. DOI: 10.3390/ma17030754

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- How does a vacuum tube nitriding system control the reaction environment? Precision Surface Hardening for AISI 304

- What types of atmospheres can a horizontal electric furnace control? Master Material Processing with Precision

- How do three-zone tube furnaces support scalability? Bridge Lab to Industrial Production Seamlessly

- How does gas flow control in a tube furnace influence the quality of NMC811? Master Stable Calcination Environments

- What are the main applications of drop tube furnaces? Unlock Precision in High-Temperature Processes

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What is an atmosphere tube furnace? Unlock Precise High-Temperature Processing

- How does the heating method of a fluidized bed vertical tube furnace differ from ordinary tube furnaces? Discover Key Differences for Better Lab Efficiency