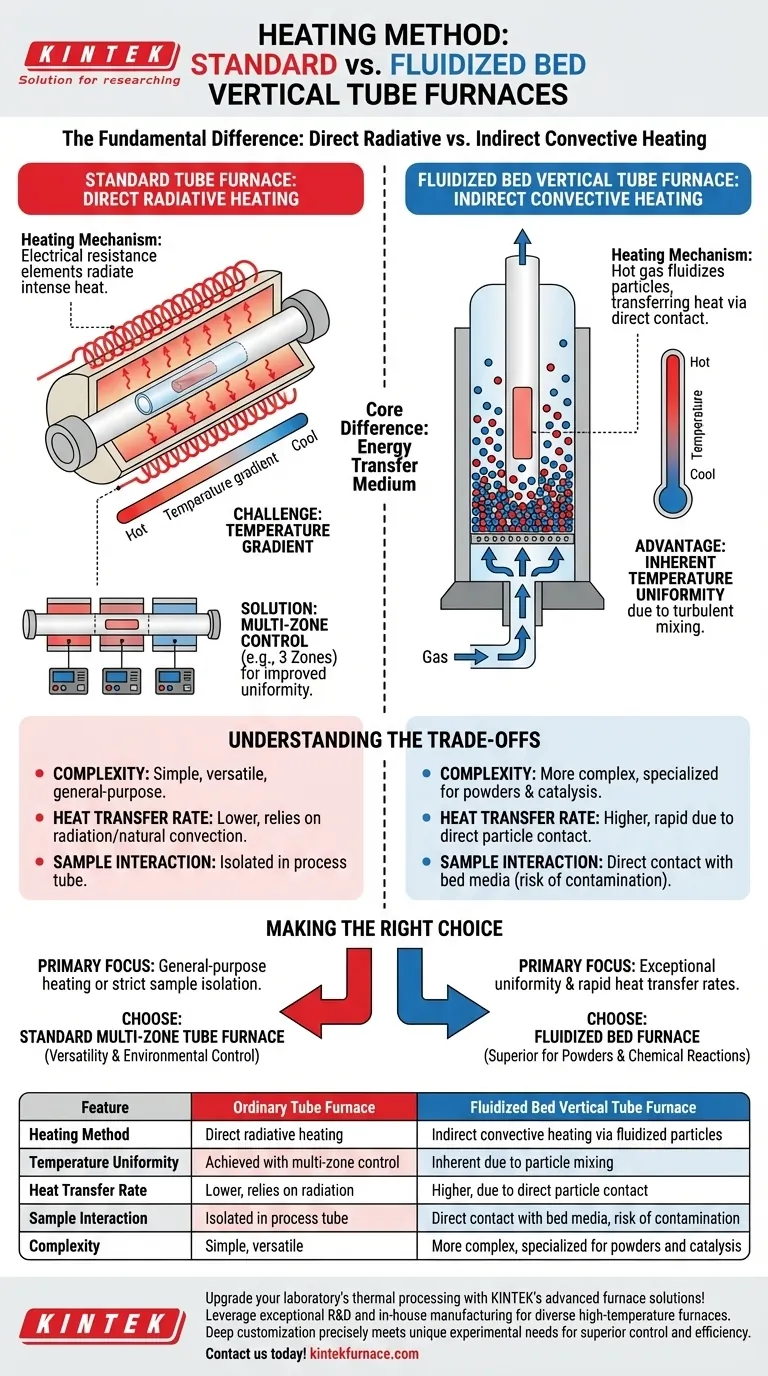

At its core, the fundamental difference lies in the medium used to transfer energy. An ordinary tube furnace heats the processing tube directly via radiation from heating elements, whereas a fluidized bed vertical tube furnace uses a flow of hot gas to energize a bed of solid particles, which then engulfs the sample and transfers heat through direct contact.

The decision between these furnaces is a choice between direct radiative heating and indirect convective heating. While a standard furnace approximates temperature uniformity through multiple control zones, a fluidized bed furnace achieves superior uniformity and efficiency inherently through the physics of its particle-based heating medium.

The Standard Tube Furnace: Direct Radiative Heating

A standard tube furnace is the workhorse of many labs and industries, relying on a straightforward and established heating principle.

The Heating Mechanism

These furnaces use electrical resistance heating elements, often made of materials like Kanthal or MoSi2. These elements are positioned around a ceramic tube and generate intense heat, which radiates inward to heat the furnace wall and the air or inert gas inside. The sample within the processing tube is heated primarily by this radiation.

The Challenge of Uniformity

Direct radiation naturally creates a temperature gradient. The areas of the tube closest to the heating elements become hotter, while areas further away remain cooler. This can lead to inconsistent processing results, especially for temperature-sensitive materials.

The Solution: Multi-Zone Control

To combat this, advanced tube furnaces are divided into multiple heating zones (commonly three). Each zone has its own independent thermocouple and controller, allowing you to program a specific temperature profile along the length of the tube to create a larger, more uniform hot zone.

The Fluidized Bed Furnace: Indirect Convective Heating

A fluidized bed furnace operates on a more complex but highly effective principle, transforming solid particles into a fluid-like heat transfer medium.

The "Fluidized" Principle

Imagine a container filled with fine sand. If you force a gas (like air or nitrogen) up through the bottom of the container at the right velocity, the sand particles will become suspended in the gas flow. The entire mixture of gas and particles begins to churn and bubble, behaving much like a boiling liquid. This is a fluidized bed.

The Heat Transfer Mechanism

In this furnace, heating elements heat the gas before it enters the bed. This hot gas flows up and transfers its energy to the millions of suspended solid particles. A sample immersed in this bed is therefore in direct, constant contact with countless tiny, hot particles, resulting in extremely rapid and efficient heat transfer.

Inherent Temperature Uniformity

The constant, turbulent motion of the particles acts as a powerful mixing agent. This dynamic movement eliminates hot and cold spots, ensuring that the temperature throughout the entire bed is exceptionally uniform without the need for complex multi-zone controls.

Understanding the Trade-offs

Choosing the right furnace requires acknowledging the inherent advantages and disadvantages of each technology.

Complexity and Application

A standard tube furnace is mechanically simple and serves as a versatile, general-purpose tool. A fluidized bed system is more specialized, with added complexity from its gas flow controls, making it ideal for processes where ultimate uniformity is critical, such as in catalytic cracking or the heat treatment of fine powders.

Heat Transfer Rate

The direct particle-to-surface contact in a fluidized bed provides a much higher heat transfer coefficient than the radiation and natural convection in a standard tube furnace. This means samples can be brought to temperature much more quickly.

Sample Interaction

In a standard furnace, the sample is typically isolated within a process tube. In a fluidized bed, the sample is in direct contact with the bed media (e.g., alumina or sand particles), which could be a source of contamination for ultra-pure applications.

Making the Right Choice for Your Process

Your final decision should be guided by the specific thermal requirements of your application.

- If your primary focus is general-purpose heating or processes requiring strict sample isolation: A standard multi-zone tube furnace offers excellent versatility and environmental control.

- If your primary focus is exceptional temperature uniformity and rapid heat transfer rates: A fluidized bed furnace is the superior choice, especially for treating powders or enabling specific chemical reactions.

Understanding this fundamental difference in heat transfer allows you to select not just a furnace, but the precise thermal environment your process requires to succeed.

Summary Table:

| Feature | Ordinary Tube Furnace | Fluidized Bed Vertical Tube Furnace |

|---|---|---|

| Heating Method | Direct radiative heating | Indirect convective heating via fluidized particles |

| Temperature Uniformity | Achieved with multi-zone control | Inherent due to particle mixing |

| Heat Transfer Rate | Lower, relies on radiation | Higher, due to direct particle contact |

| Sample Interaction | Isolated in process tube | Direct contact with bed media, risk of contamination |

| Complexity | Simple, versatile | More complex, specialized for powders and catalysis |

Upgrade your laboratory's thermal processing with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs for superior temperature control and efficiency. Contact us today to discuss how our tailored solutions can enhance your research and production processes!

Visual Guide

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What industries benefit from the use of tube furnaces? Unlock Precision in Semiconductor and Battery Tech

- Why are tubular furnaces important in material testing and research? Unlock Precision for Advanced Materials Development

- In which industries is the tube furnace commonly used? Essential for Materials Science, Energy, and More

- What types of production processes benefit from the thermal uniformity of tube furnaces? Enhance Precision in Material Processing

- What is flash vacuum pyrolysis and how is a tube furnace utilized in this process? Unlock High-Temp Chemical Reactions