At their core, three-zone tube furnaces are designed to solve the critical challenge of scalability in advanced materials. They allow a thermal process perfected in a laboratory to be directly replicated at pilot and industrial scales, ensuring that the material's properties remain consistent. This continuity between research and production dramatically reduces development time and financial risk.

The fundamental value of a three-zone furnace is its ability to create a precisely uniform temperature profile over a significant length. This "thermal recipe" can be applied to furnaces of any size, providing a reliable bridge from small-scale discovery to large-scale commercialization.

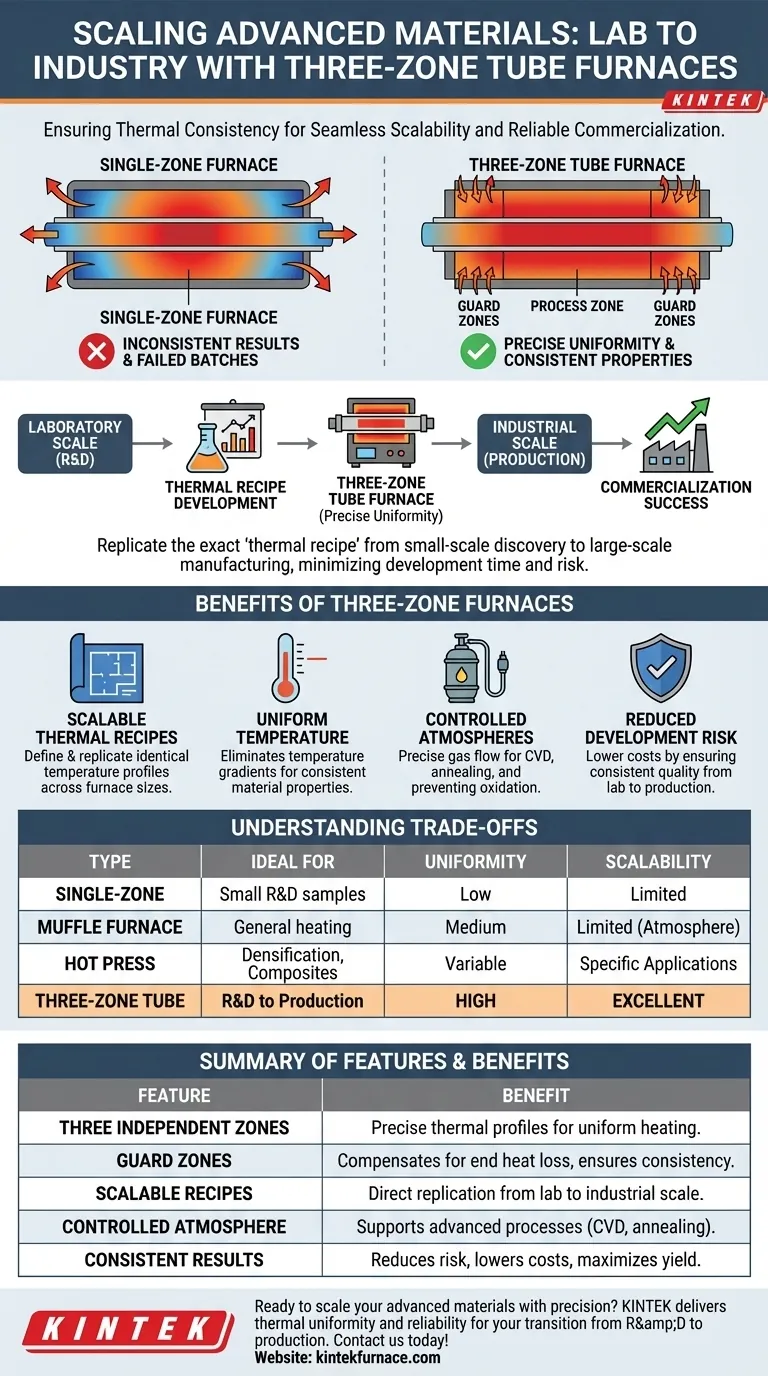

The Core Challenge: From Lab Bench to Production Line

Scaling up the synthesis of advanced materials is notoriously difficult. A process that works perfectly for a small sample in a research lab often fails when attempted on a larger scale, leading to costly delays and inconsistent products.

The Problem of Thermal Uniformity

In any furnace, heat naturally escapes from the ends of the heating chamber. A simple, single-zone furnace is hottest in the middle and cooler at the ends, creating a significant temperature gradient.

For a very small sample placed perfectly in the center, this may not be an issue. However, for larger components or continuous processes, parts of the material will be exposed to different temperatures, leading to non-uniform results.

How Inconsistency Derails Production

This lack of thermal uniformity can be catastrophic for advanced materials. It can lead to inconsistent crystal growth, unpredictable material density, mechanical weak points, and poor performance. A single failed batch at an industrial scale represents a significant loss of time, energy, and raw materials.

How Three-Zone Furnaces Deliver Precision at Scale

Three-zone tube furnaces directly address the problem of thermal uniformity through a more sophisticated design. They don't just heat the material; they actively manage the thermal environment.

The Principle: Guard and Process Zones

A three-zone furnace divides its heating chamber into three independently controlled sections. The large, central section is the process zone, where the material is treated.

The two smaller sections at either end are guard zones. Their sole purpose is to compensate for the natural heat loss at the ends of the tube. By running these guard zones at a slightly higher temperature, they create a thermal buffer that ensures the central process zone remains exceptionally uniform from end to end.

Replicating the "Thermal Recipe"

This design allows you to define a precise temperature profile, or "thermal recipe," for your material. This recipe—the exact temperature, ramp-up/cool-down rates, and hold times—is what determines the final properties of the material.

Because this profile can be programmed identically into a small lab furnace or a large production furnace, the process becomes scalable. You are no longer guessing; you are replicating the exact conditions that you know produce the desired result.

Enabling Controlled Atmospheres

The "tube" format is critical for many advanced processes like chemical vapor deposition (CVD), annealing, or purification. It allows for the precise control of the gas atmosphere flowing over the material, preventing unwanted reactions like oxidation and enabling the deposition of thin films.

Understanding the Trade-offs and Alternatives

While powerful, a three-zone furnace is not always the necessary choice. Understanding the alternatives clarifies its specific advantages.

When a Single-Zone Furnace Is Sufficient

For heat-treating very small samples where the short, uniform hot zone in the center is adequate, a simpler and more cost-effective single-zone furnace can be a practical choice. They are excellent for fundamental research where scalability is not an immediate concern.

The Role of Muffle and Hot Press Furnaces

Muffle furnaces are workhorses for general-purpose heating in air or an inert atmosphere, but they lack the precise atmospheric control of a tube furnace. Vacuum hot press furnaces add the dimension of high pressure, used for densifying materials and creating composites—a different process category altogether.

Cost and Complexity

The primary trade-off is complexity. A three-zone furnace has more heating elements, more sensors, and a more sophisticated controller. This makes them more expensive upfront than a single-zone furnace, representing a strategic investment in process control and scalability.

Making the Right Choice for Your Goal

Selecting the right furnace depends entirely on your specific objective, balancing precision requirements with budget and scale.

- If your primary focus is R&D and developing a scalable process: A three-zone furnace is a strategic investment that ensures your lab results can be reliably transferred to production.

- If your primary focus is high-volume, consistent manufacturing: The superior temperature uniformity of a three-zone system is essential for maximizing yield and ensuring every part meets specification.

- If your primary focus is basic research on small samples without immediate scale-up plans: A single-zone tube furnace or muffle furnace may offer the most cost-effective solution.

Ultimately, mastering the thermal process is the key to unlocking the full potential of any advanced material.

Summary Table:

| Feature | Benefit |

|---|---|

| Three independently controlled zones | Enables precise temperature profiles for uniform heating |

| Guard zones at ends | Compensates for heat loss, maintaining thermal consistency |

| Scalable thermal recipes | Allows direct replication from lab to industrial scales |

| Controlled atmosphere capability | Supports processes like CVD and annealing without oxidation |

| Reduces development time and risk | Lowers costs by ensuring material property consistency |

Ready to scale your advanced materials with precision? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide high-temperature furnace solutions tailored for diverse laboratories. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is enhanced by strong deep customization capabilities to meet your unique experimental needs. Whether you're transitioning from R&D to production or optimizing industrial processes, our three-zone tube furnaces deliver the thermal uniformity and reliability you require. Contact us today to discuss how we can support your scalability goals and enhance your material development efficiency!

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- What is the purpose of the rotation mechanism in a rotary tube furnace? Achieve Uniform Heating and Enhanced Process Control

- What is the basic construction of a rotary tube furnace? Key Components for Uniform Heating

- What supplementary features can enhance rotary tube furnace performance? Boost Efficiency with Precision Control

- What types of materials are suitable for processing in rotary tube furnaces? Ideal for Free-Flowing Powders and Granules

- What factors should be considered when selecting a tube for a rotary tube furnace? Ensure Optimal Performance and Longevity