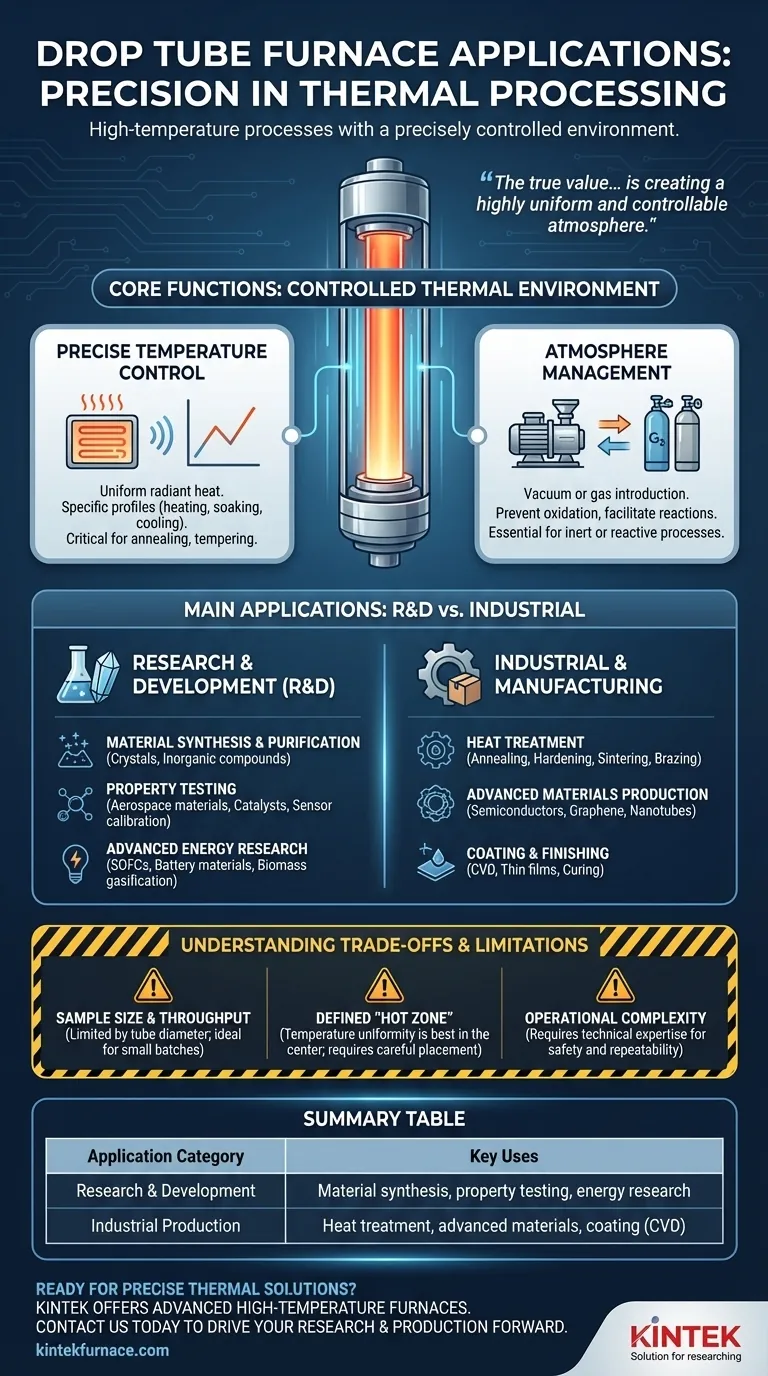

In short, drop tube furnaces are primarily used for high-temperature thermal processes that require a precisely controlled environment. Their main applications fall into two broad categories: materials science research—including synthesis, purification, and property testing—and specialized industrial production, such as heat treatment of metals, manufacturing electronic components, and developing advanced materials like graphene.

The true value of a drop tube furnace isn't just its ability to get hot, but its capacity to create a highly uniform and controllable atmosphere. This makes it an indispensable tool for developing and processing materials where precision is non-negotiable.

The Core Function: A Controlled Thermal Environment

A tube furnace's defining feature is its cylindrical chamber. This design is exceptionally effective at creating a zone of uniform temperature and allows for precise control over the internal atmosphere, which is why it's central to so many advanced applications.

Precise Temperature Control

The heating elements surround the tube, providing even, radiant heat. This allows for creating specific temperature profiles, including rapid heating, extended "soaking" at a target temperature, and controlled cooling. This level of control is critical for processes like annealing and tempering.

Atmosphere Management

The sealed tube design makes it simple to manage the internal environment. You can pull a vacuum to remove contaminants or introduce specific gases. This is essential for preventing oxidation with inert gases (like argon) or for facilitating specific chemical reactions with reactive gases.

Key Applications in Research and Development (R&D)

In a laboratory setting, tube furnaces are the workhorses for exploring the frontiers of material science. Their flexibility allows researchers to test new ideas and characterize novel materials.

Material Synthesis and Purification

Researchers use tube furnaces for synthesizing inorganic compounds, growing pure crystals, and purifying materials through processes like sublimation or high-temperature drying.

Property Testing and Analysis

Tube furnaces are used to study how materials behave under extreme thermal stress. This is critical for aerospace materials testing, catalyst research, mineral analysis, and calibrating high-temperature sensors like thermocouples.

Advanced Energy Research

The development of next-generation energy solutions relies heavily on tube furnaces. They are used for testing solid oxide fuel cells (SOFCs), developing new battery materials, and studying processes like biomass gasification and hydrogen pyrolysis.

Industrial and Manufacturing Processes

Beyond the lab, tube furnaces are integral to many specialized, high-value manufacturing workflows where process control directly impacts product quality.

Heat Treatment of Materials

This is a classic application. Processes like annealing (to soften metals), hardening (to increase strength), sintering (to fuse powders into a solid), and brazing (to join components) are all performed in tube furnaces.

Production of Advanced Materials

The manufacturing of high-tech materials often requires the precise conditions of a tube furnace. Key examples include producing semiconductors, graphene, carbon nanotubes, and specialized polymer composites.

Coating and Finishing

Tube furnaces are used for chemical vapor deposition (CVD), where a gas reacts on a heated surface to create a thin film or coating. They are also used for drying and curing specialized coatings that require high heat.

Understanding the Trade-offs

While incredibly versatile, tube furnaces are not the right tool for every job. Understanding their limitations is key to using them effectively.

Limitation: Sample Size and Throughput

The diameter of the tube inherently limits the size of the sample. This makes tube furnaces ideal for research, testing, and small-batch production, but unsuitable for high-volume, mass-production applications.

Limitation: The "Hot Zone"

Perfect temperature uniformity is a goal, not a guarantee. There is always a defined "hot zone" in the center of the furnace, with temperatures tapering off toward the ends. Processing long parts or large batches requires careful placement to ensure everything receives the same thermal treatment.

Limitation: Operational Complexity

Operating a tube furnace, especially with vacuum systems or reactive gases, requires technical expertise. It is not a simple "set it and forget it" device and demands a knowledgeable operator to ensure safety and process repeatability.

Making the Right Choice for Your Goal

To determine if a drop tube furnace fits your needs, consider your primary objective.

- If your primary focus is fundamental research or material discovery: A tube furnace is an essential tool for synthesizing compounds, testing material properties, and exploring new chemical processes in a controlled setting.

- If your primary focus is process development and optimization: A tube furnace allows you to test and refine heat treatment cycles, catalyst reactions, or coating parameters on a small scale before investing in larger industrial equipment.

- If your primary focus is specialized, small-batch production: This furnace is ideal for manufacturing high-value components like sensors, advanced ceramics, or purified noble metals where precision outweighs the need for mass throughput.

Ultimately, a drop tube furnace is the definitive tool for any process that demands precise thermal and atmospheric control over a material.

Summary Table:

| Application Category | Key Uses |

|---|---|

| Research & Development | Material synthesis, property testing, energy research (e.g., SOFCs, battery materials) |

| Industrial Production | Heat treatment (annealing, sintering), advanced materials (graphene, semiconductors), coating (CVD) |

Ready to enhance your lab's capabilities with precise thermal solutions? KINTEK offers advanced high-temperature furnaces, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, backed by deep customization to meet your unique needs. Contact us today to discuss how our expertise can drive your research and production forward!

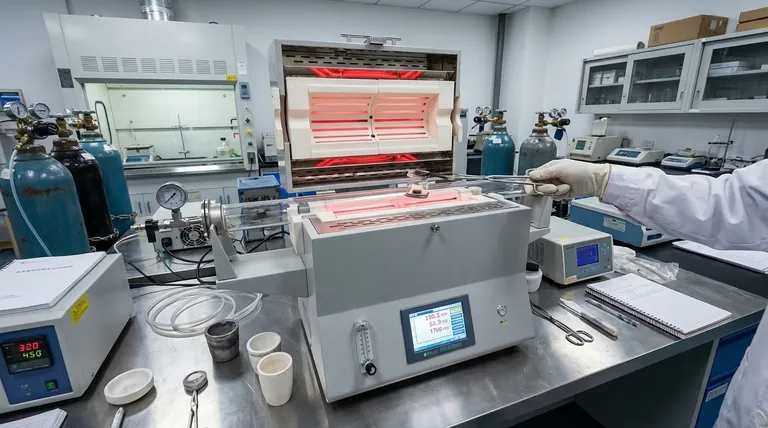

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis