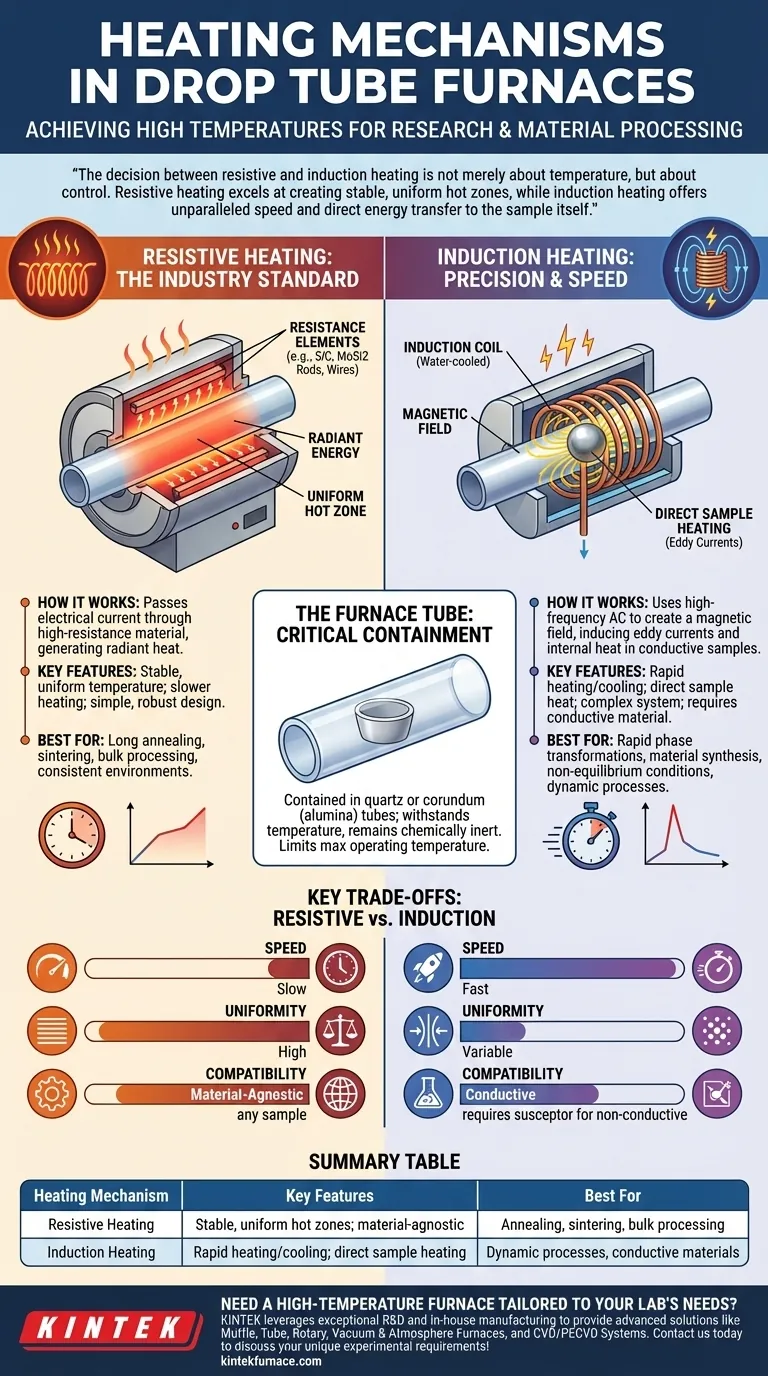

At their core, drop tube furnaces employ two primary heating mechanisms to achieve the high temperatures necessary for research and material processing. The most common methods are resistive heating, which uses elements that glow hot when electricity passes through them, and medium-frequency induction heating, which uses magnetic fields to heat a conductive sample directly.

The decision between resistive and induction heating is not merely about temperature, but about control. Resistive heating excels at creating stable, uniform hot zones, while induction heating offers unparalleled speed and direct energy transfer to the sample itself.

The Two Primary Heating Principles

To understand which furnace is right for your work, it’s essential to grasp how each heating method functions and what it's best suited for.

Resistive Heating: The Industry Standard

Resistive heating is the most prevalent technology in laboratory furnaces. It operates on the simple principle of passing an electrical current through a material with high electrical resistance, causing it to heat up and radiate energy into the furnace chamber.

The specific heating elements are chosen for their ability to withstand extreme temperatures. Common types include resistance wires, durable silicon carbon (SiC) rods, and high-performance silicon molybdenum (MoSi2) rods.

These elements are arranged around the furnace tube to create a uniform temperature zone, making this method ideal for processes that require stability and consistency over long periods.

Induction Heating: Precision and Speed

Induction heating works on a completely different principle. It uses a high-frequency alternating current passed through a copper coil to generate a powerful and rapidly changing magnetic field.

When a conductive material (like a metal alloy sample) is placed inside this field, the magnetic field induces electrical "eddy currents" within the sample itself. The sample's own internal resistance to these currents generates intense, rapid heat from the inside out.

This method allows for extremely fast heating and cooling rates because it heats the sample directly, not the entire furnace chamber.

The Critical Role of the Furnace Tube

Regardless of the heating method, the sample is contained within a tube. This tube, typically made of quartz or high-purity corundum (alumina), must withstand the target temperatures and remain chemically inert to avoid contaminating the sample. The choice of heating element and the maximum operating temperature are therefore limited by the thermal properties of the tube.

Understanding the Trade-offs: Resistive vs. Induction

Choosing the correct heating mechanism involves balancing speed, uniformity, material compatibility, and cost. Neither method is universally superior; they are suited for different goals.

Heating Rate and Control

Induction heating offers exceptionally rapid temperature ramp-up and cool-down. This is ideal for studying dynamic processes like rapid phase transformations or simulating conditions where thermal shock is a factor.

Resistive heating has a much slower thermal response. It heats the elements, which in turn heat the furnace insulation and tube, which finally heats the sample. This thermal mass provides excellent temperature stability, perfect for long annealing or sintering processes requiring a consistent environment.

Material Compatibility

Resistive heating is material-agnostic. It heats the furnace chamber, and anything inside that chamber will be heated by radiation and convection. This makes it suitable for powders, ceramics, polymers, and metals alike.

Induction heating is more restrictive. It requires the sample itself to be electrically conductive. For non-conductive materials like many ceramics, a conductive sleeve called a susceptor (often made of graphite) must be placed around the sample to absorb the magnetic energy and transfer heat to it.

System Complexity and Uniformity

Resistive furnaces are generally simpler, more robust, and less expensive. Their design naturally produces a large, uniform hot zone, which is critical for processing bulk materials or multiple samples at once.

Induction systems are more complex, requiring a specialized power supply and water-cooled coils. Achieving a highly uniform temperature zone can be more challenging and is dependent on the coil and sample geometry.

Selecting the Right Mechanism for Your Application

The optimal heating method is the one that best serves your specific research or production goal.

- If your primary focus is uniform bulk processing or cost-effectiveness: Resistive heating is the most reliable and straightforward choice, ideal for annealing, sintering, or general heat treatment.

- If your primary focus is rapid thermal cycling or direct sample heating: Induction heating offers unparalleled speed and control, making it perfect for materials synthesis and studying non-equilibrium conditions.

- If you are working with non-conductive powders or materials: Resistive heating is the simplest solution, though an induction furnace can be used if you incorporate a conductive susceptor.

Understanding these fundamental differences empowers you to select a furnace configuration that directly serves your scientific or industrial objective.

Summary Table:

| Heating Mechanism | Key Features | Best For |

|---|---|---|

| Resistive Heating | Stable, uniform hot zones; material-agnostic | Annealing, sintering, bulk processing |

| Induction Heating | Rapid heating/cooling; direct sample heating | Dynamic processes, conductive materials |

Need a high-temperature furnace tailored to your lab's unique needs? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure precise alignment with your experimental requirements, whether you prioritize uniform heating or rapid thermal cycling. Contact us today to discuss how our furnaces can enhance your research efficiency and results!

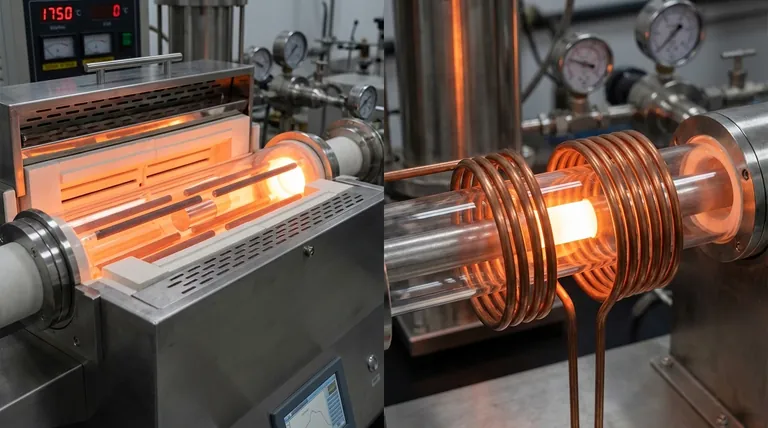

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide