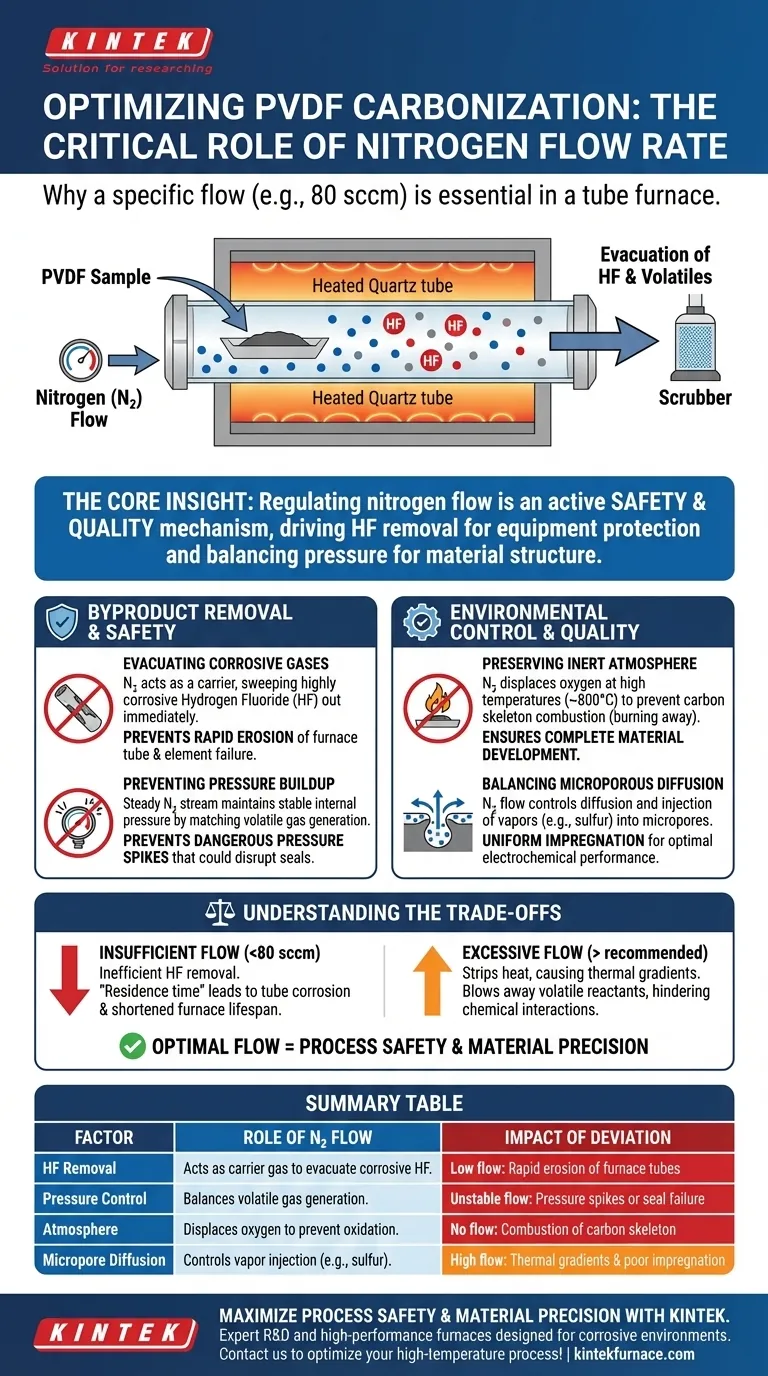

Maintaining a specific nitrogen flow rate (such as 80 sccm) within a tube furnace is strictly necessary to manage the hazardous byproducts of Polyvinylidene Fluoride (PVDF) decomposition. Its primary function is to act as a carrier gas that actively evacuates corrosive Hydrogen Fluoride (HF) gas, preventing severe damage to your equipment while stabilizing the internal pressure required for consistent carbonization.

The Core Insight Regulating nitrogen flow during PVDF carbonization is an active safety and quality control mechanism, not just a passive shield. It drives the removal of corrosive HF gas to protect the furnace tube and balances internal pressure to ensure the correct diffusion of elements into the material's microporous structure.

The Critical Role of Byproduct Removal

Evacuating Corrosive Gases

When PVDF undergoes high-temperature carbonization, it decomposes and releases Hydrogen Fluoride (HF). This is a highly corrosive gas.

A calculated nitrogen flow acts as a carrier mechanism. It sweeps the HF out of the heating zone immediately after it is generated.

Without this flow, HF would accumulate, leading to the rapid erosion of the furnace tube and potential failure of the heating elements.

Preventing Pressure Buildup

The decomposition of PVDF releases volatiles that can increase the internal pressure of a closed system.

A steady nitrogen stream maintains a stable internal pressure. It ensures that the volume of gas leaving the tube matches the generation of volatiles.

This prevents dangerous pressure spikes that could disrupt the seal or damage the quartz/ceramic tube.

Environmental Control and Structural Integrity

Preserving the Inert Atmosphere

At temperatures like 800 °C, carbon is highly susceptible to oxidation.

The nitrogen flow creates a strictly inert protective atmosphere. It displaces oxygen, preventing the carbon skeleton from combusting (burning away) before it fully forms.

This oxygen-deficient environment is critical for ensuring the complete development of the carbon material skeleton.

Balancing Microporous Diffusion

If your process involves the injection of other elements (such as sulfur vapor for battery applications), the flow rate becomes a tuning variable.

The gas flow ensures that the diffusion and injection of vapors into the microporous structures remain in a balanced state.

This balance allows for uniform impregnation of the carbon pores, which is essential for the final material's electrochemical performance.

Understanding the Trade-offs

The Risk of Insufficient Flow

If the flow rate is too low (below the recommended ~80 sccm), the removal of HF becomes inefficient.

This leads to "residence time" where corrosive gases sit in contact with the tube walls, significantly shortening the lifespan of your furnace.

The Risk of Excessive Flow

While not explicitly detailed in the primary text, standard furnace operations dictate that excessive flow can be detrimental.

Too high a flow rate can strip heat away from the sample, causing thermal gradients. It may also blow volatile reactants away too quickly, preventing necessary chemical interactions within the micropores.

Making the Right Choice for Your Process

To optimize your PVDF carbonization, you must align the flow rate with your specific constraints:

- If your primary focus is Equipment Longevity: Ensure the flow rate is sufficient to continuously evacuate HF gas; failing to do so will corrode your furnace tube rapidly.

- If your primary focus is Material Quality: Maintain a strictly stable flow to prevent pressure fluctuations that could collapse the microporous structure or cause uneven sulfur diffusion.

Consistency is key: a stable flow rate protects your hardware today and ensures the reproducibility of your material tomorrow.

Summary Table:

| Factor | Role of Nitrogen Flow | Impact of Deviation |

|---|---|---|

| HF Removal | Acts as a carrier gas to evacuate corrosive HF | Low flow: Rapid erosion of furnace tubes |

| Pressure Control | Balances volatile gas generation | Unstable flow: Pressure spikes or seal failure |

| Atmosphere | Displaces oxygen to prevent oxidation | No flow: Combustion of the carbon skeleton |

| Micropore Diffusion | Controls vapor injection (e.g., sulfur) | High flow: Thermal gradients and poor impregnation |

Maximize Process Safety and Material Precision with KINTEK

Protect your investment and ensure superior carbonization results. At KINTEK, we understand that handling materials like PVDF requires precise control over atmospheres and byproducts. Backed by expert R&D and manufacturing, we offer high-performance Tube, Muffle, Rotary, and Vacuum furnaces specifically designed to withstand corrosive environments and maintain stable gas flow for unique lab needs.

Ready to optimize your high-temperature process? Contact our technical experts today to find the perfectly customizable system for your research.

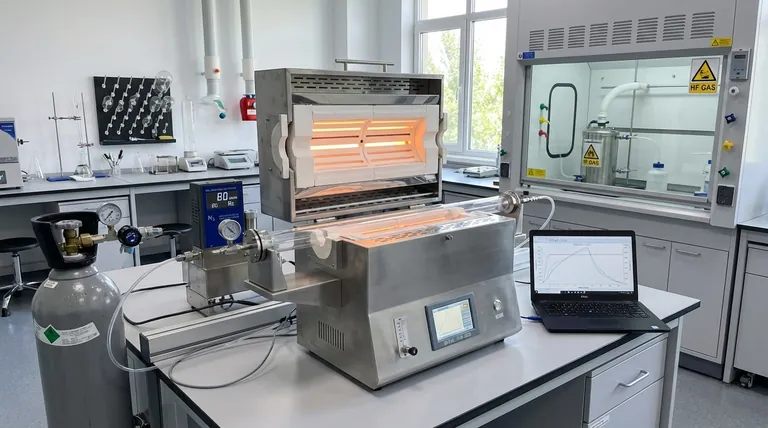

Visual Guide

References

- Jianjiao Wang. An S-Infused/S, F-Codoped PVDF-Derived Carbon as a High-Performance Anode for Sodium-Ion Batteries. DOI: 10.3390/ma18174018

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What role does a high-temperature tube furnace play in converting polymer precursors? Precision Synthesis Guide

- What materials are required for high-temperature operation in tube furnaces? Choose the Right Tube for Your Lab

- What benefits does a horizontal tube furnace offer? Achieve Precise Heat Control and Easy Access for Your Lab

- What are the key features of a 70mm tube furnace? Unlock High-Temp Precision for Your Lab

- What are the key takeaways regarding tubular furnaces and materials science? Unlock Precision Thermal Processing for Advanced Materials

- How does a laboratory tube furnace ensure the structural stability and quality of hard carbon? Expert Carbonization

- Why is a tube furnace with 5% hydrogen/argon mixed atmosphere necessary for PtPd_CoNiCu/C high-entropy alloys?

- How does a high-temperature Tube Furnace facilitate the preparation of Activated Straw Char? Expert Processing Tips