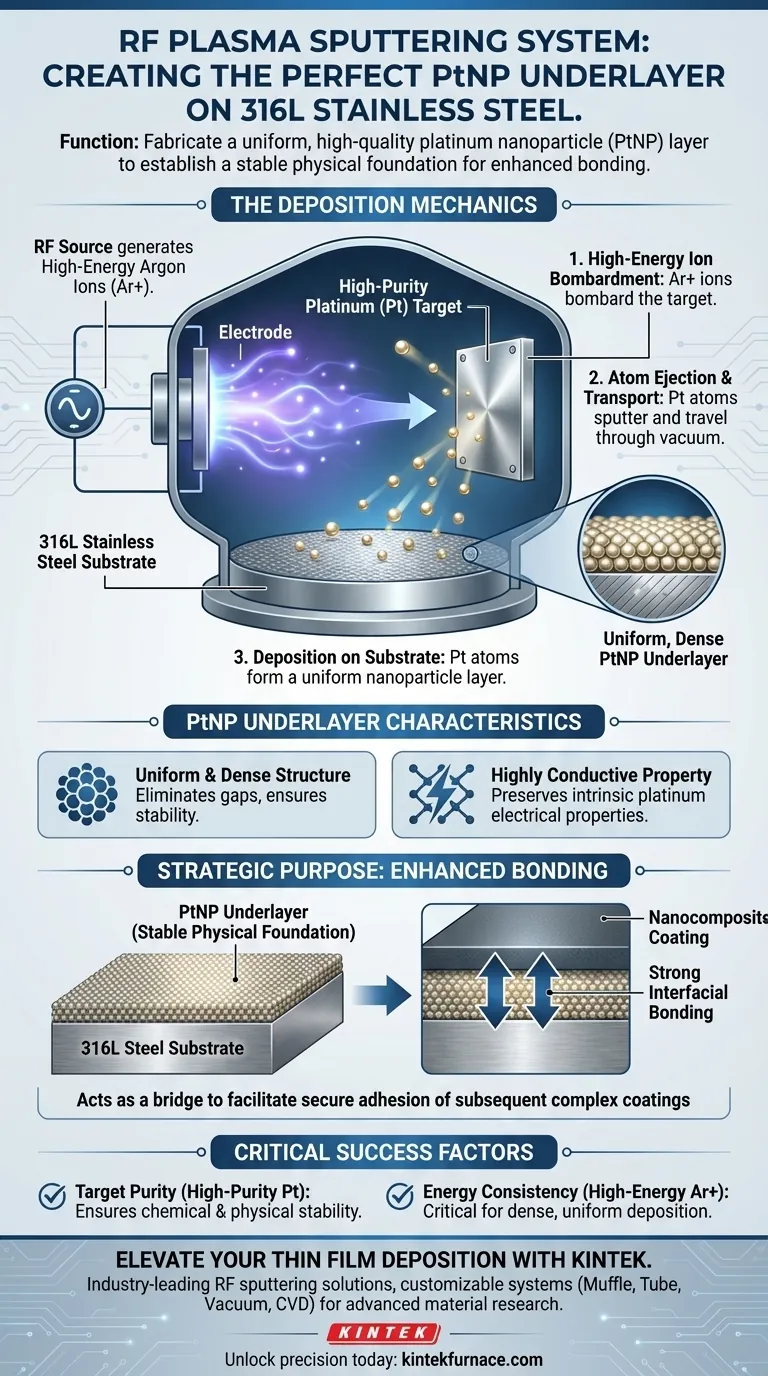

The primary function of a radio frequency (RF) plasma sputtering system in this context is to fabricate a specific, high-quality intermediate layer on 316L stainless steel. By utilizing high-energy argon ions to bombard a high-purity platinum target, the system ejects platinum atoms that deposit onto the steel, creating a uniform platinum nanoparticle (PtNP) underlayer.

Core Takeaway The RF sputtering system acts as an interface engineer. Its purpose is not just to coat the steel, but to establish a stable physical foundation that significantly enhances interfacial bonding, ensuring that subsequent nanocomposite coatings adhere securely to the substrate.

The Mechanics of Deposition

High-Energy Ion Bombardment

The process begins with the generation of high-energy argon ions within the system.

These ions are directed to bombard a target made of high-purity platinum.

Atom Ejection and Settlement

Upon impact, the energy transfer causes platinum atoms to sputter (eject) from the target.

These atoms travel through the vacuum chamber and deposit directly onto the surface of the 316L stainless steel substrate.

Characteristics of the PtNP Underlayer

Structural Uniformity

The RF sputtering process is tuned to ensure the deposited platinum atoms form a uniform and dense layer.

This uniformity is critical, as it eliminates gaps or weak points on the steel surface that could compromise future coating layers.

Functional Conductivity

Beyond structure, the deposition creates a highly conductive nanoparticle layer.

This electrical property is intrinsic to the platinum material and is preserved through the sputtering process.

The Strategic Purpose: Solving the Adhesion Problem

Creating a Physical Foundation

The ultimate goal of this system is to modify the surface properties of the raw stainless steel.

The resulting PtNP underlayer provides a stable physical foundation that the original steel surface lacks on its own.

Enhancing Interfacial Bonding

This foundation serves a specific downstream purpose: facilitating the application of nanocomposite coatings.

By acting as a bridge, the underlayer significantly enhances the interfacial bonding between the steel substrate and these subsequent complex coatings.

Critical Success Factors

Dependency on Target Purity

The quality of the underlayer is directly tied to the input materials.

The system relies on a high-purity platinum target to ensure the deposited layer maintains the necessary chemical and physical stability.

The Role of Energy Consistency

The density of the coating depends on the consistent application of high-energy argon ions.

Insufficient ion energy would fail to sputter the platinum effectively, leading to a sparse or uneven underlayer that cannot support subsequent coatings.

Making the Right Choice for Your Goal

The RF plasma sputtering system is a precise tool designed to bridge the gap between a raw substrate and a functional coating.

- If your primary focus is Durability: Ensure the system settings prioritize a dense and uniform deposition to create the most stable physical foundation possible.

- If your primary focus is Adhesion: Recognize that the PtNP layer is the key to enhanced interfacial bonding, making it strictly necessary before applying nanocomposite coatings.

The RF sputtering system transforms 316L stainless steel from a simple metal substrate into a primed, conductive surface ready for advanced composite applications.

Summary Table:

| Process Component | Role in PtNP Fabrication |

|---|---|

| Energy Source | High-energy argon ions bombard the platinum target |

| Target Material | High-purity platinum for chemical and physical stability |

| Deposition Result | Uniform, dense platinum nanoparticle (PtNP) underlayer |

| Primary Function | Enhances interfacial bonding for nanocomposite coatings |

| Substrate | 316L Stainless Steel substrate surface modification |

Elevate Your Thin Film Deposition with KINTEK

Are you looking to achieve superior interfacial bonding and high-purity nanoparticle underlayers? KINTEK provides industry-leading RF sputtering solutions tailored for advanced material research. Backed by expert R&D and manufacturing, we offer customizable Muffle, Tube, Rotary, Vacuum, and CVD systems, along with specialized lab high-temp furnaces to meet your unique thin-film requirements.

Unlock precision in your lab today—Contact our technical experts for a custom quote!

Visual Guide

References

- Noor Waleed Ibrahim, Layla M. Hasan. Corrosion protection of stainless steel by Nanocomposite coating prepared by Pulsed laser ablation in liquid. DOI: 10.21203/rs.3.rs-7263886/v1

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

People Also Ask

- What is the process for synthesizing transition metal dichalcogenides (TMDs) using CVD tube furnaces? Master High-Quality Thin Film Growth

- What role does molten Tin (Sn) play in B-CVD growth of graphene? Engineering High-Performance Wrinkled Structures

- What role do CVD furnaces play in the semiconductor industry? Essential for Precise Thin-Film Deposition in Chip Fabrication

- What is a CVD used for? Engineer High-Performance Thin Films for Advanced Applications

- What role does a vacuum thermal evaporation system play in the fabrication of Cu13Se52Bi35 thin films? Expert Guide

- How does chemical vapour deposition (CVD) differ from PVD? Key Differences in Thin-Film Coating Methods

- Why is the distance between source and substrate fixed in ZTO thin film deposition? Unlock Precision and Uniformity

- What are the disadvantages of CVD? Weighing High Costs, Complexity, and Constraints