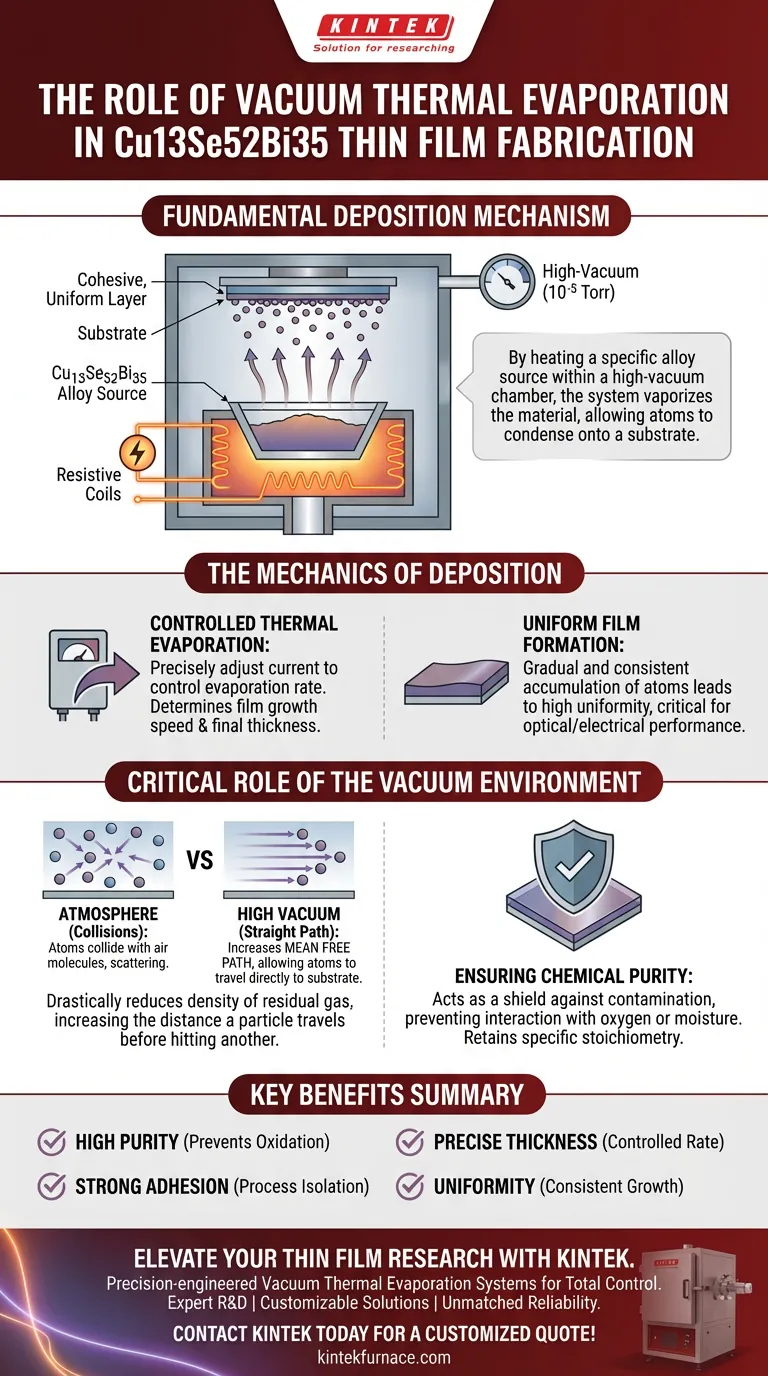

The vacuum thermal evaporation system serves as the fundamental deposition mechanism for fabricating Cu13Se52Bi35 thin films. By heating a specific alloy source within a high-vacuum chamber (typically 10⁻⁵ Torr), the system vaporizes the material, allowing atoms to condense onto a substrate and form a cohesive, uniform layer.

Core Insight The system’s primary value lies in its ability to isolate the deposition process from atmospheric interference. By maximizing the mean free path of particles in a vacuum, it ensures the Cu13Se52Bi35 film achieves high purity, precise thickness, and strong adhesion to the substrate.

The Mechanics of Deposition

To understand how high-quality Cu13Se52Bi35 films are created, one must look at the specific physical controls the system offers.

Controlled Thermal Evaporation

The process begins by applying an electrical current to heat the evaporation source containing the Cu13Se52Bi35 alloy.

Researchers control the evaporation rate by precisely adjusting this current.

This thermal regulation is the primary lever for determining how fast the film grows and its final thickness.

Uniform Film Formation

As the alloy evaporates, atoms travel from the source to the substrate.

Because the rate of evaporation is controlled, the accumulation of atoms is gradual and consistent.

This results in a film with high uniformity, which is critical for the material's subsequent optical or electrical performance.

The Critical Role of the Vacuum Environment

The "vacuum" aspect of the system is not merely for cleanliness; it is a physical requirement for the transport of material.

Increasing the Mean Free Path

In a standard atmosphere, vaporized atoms would instantly collide with air molecules.

The high-vacuum environment (10⁻⁵ Torr) drastically reduces the density of residual gas.

This increases the mean free path—the distance a particle travels before hitting another particle—allowing the Cu13Se52Bi35 atoms to travel in a straight line to the substrate without scattering.

Ensuring Chemical Purity

The vacuum environment acts as a shield against contamination.

It prevents the hot, reactive vapor from interacting with oxygen or moisture present in ambient air.

This ensures that the deposited film retains the specific stoichiometry of the Cu13Se52Bi35 alloy without degradation or oxidation.

Understanding the Trade-offs

While vacuum thermal evaporation is the core method for this material, it is important to recognize the operational constraints.

Directionality and Shadowing

Thermal evaporation is a "line-of-sight" process.

Because atoms travel in straight paths, substrates with complex, three-dimensional geometries may experience "shadowing," where certain areas receive no coating.

Sensitivity to Process Parameters

The quality of the film is strictly tied to the stability of the vacuum and the heating current.

Even minor fluctuations in the vacuum level can shorten the mean free path, leading to reduced deposition efficiency.

Similarly, instability in the heating current can cause variations in the evaporation rate, leading to uneven film thickness or poor adhesion.

Making the Right Choice for Your Goal

When configuring your evaporation system for Cu13Se52Bi35, prioritize parameters based on your specific research objectives.

- If your primary focus is Film Purity: Ensure your system can reliably maintain a base pressure of 10⁻⁵ Torr or lower to eliminate oxidation risks.

- If your primary focus is Thickness Uniformity: Invest in precise current control mechanisms to maintain a stable evaporation rate throughout the deposition cycle.

- If your primary focus is Structural Adhesion: Monitor the substrate preparation and vacuum quality, as these directly influence how well the atoms bond to the surface.

The vacuum thermal evaporation system provides the necessary physical foundation to transform raw alloy into a functional, high-quality thin film.

Summary Table:

| Feature | Role in Cu13Se52Bi35 Fabrication | Key Benefit |

|---|---|---|

| High Vacuum (10⁻⁵ Torr) | Increases mean free path of particles | Prevents oxidation & ensures chemical purity |

| Thermal Regulation | Precisely controls evaporation rate | Consistent film thickness & growth |

| Line-of-Sight Transport | Direct atom-to-substrate condensation | High-purity, cohesive layer formation |

| Process Isolation | Removes atmospheric interference | Enhanced structural adhesion & uniformity |

Elevate Your Thin Film Research with KINTEK

Precision is paramount when fabricating complex alloys like Cu13Se52Bi35. KINTEK provides industry-leading vacuum thermal evaporation systems and lab high-temp furnaces designed to give you total control over deposition parameters.

Why partner with KINTEK?

- Expert R&D: Systems engineered for high-purity results and stable evaporation rates.

- Customizable Solutions: From Muffle and Tube furnaces to advanced CVD and Vacuum systems, we tailor hardware to your unique research needs.

- Unmatched Reliability: Our equipment ensures the high-vacuum stability required for superior thin film adhesion and stoichiometry.

Ready to achieve consistent, high-quality material deposition? Contact KINTEK today for a customized quote!

Visual Guide

References

- Abduelwhab B. Alwany, Abdulnasser Abdulrahman Alfaqeer. Effect of annealing temperature on the structural and optical properties of vacuum evaporated Cu13Se52Bi35 thin films. DOI: 10.15251/cl.2024.211.99

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- MPCVD Machine System Reactor Bell-jar Resonator for Lab and Diamond Growth

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

People Also Ask

- What types of materials can be deposited using CVD in microfabrication? Explore Versatile Thin Films for Your Devices

- What is the use of CVD machine? Transform Surfaces with Atomic-Level Precision

- In what way are CVD systems applied to gas purification? Engineer Advanced Catalysts for Cleaner Synthesis Gas

- What are the benefits of using a CVD furnace? Achieve Atomic-Level Control for Superior Thin Films

- How is CVD used to coat glass? Achieve Durable, High-Volume Glass Coatings

- What is Metalorganic Chemical Vapor Deposition (MOCVD)? Master Precision Thin-Film Growth for Advanced Devices

- What are the cons of the CVD process? High Costs, Safety Risks, and Production Limits

- How does the CVD system work? Master Thin Film Deposition for Your Lab