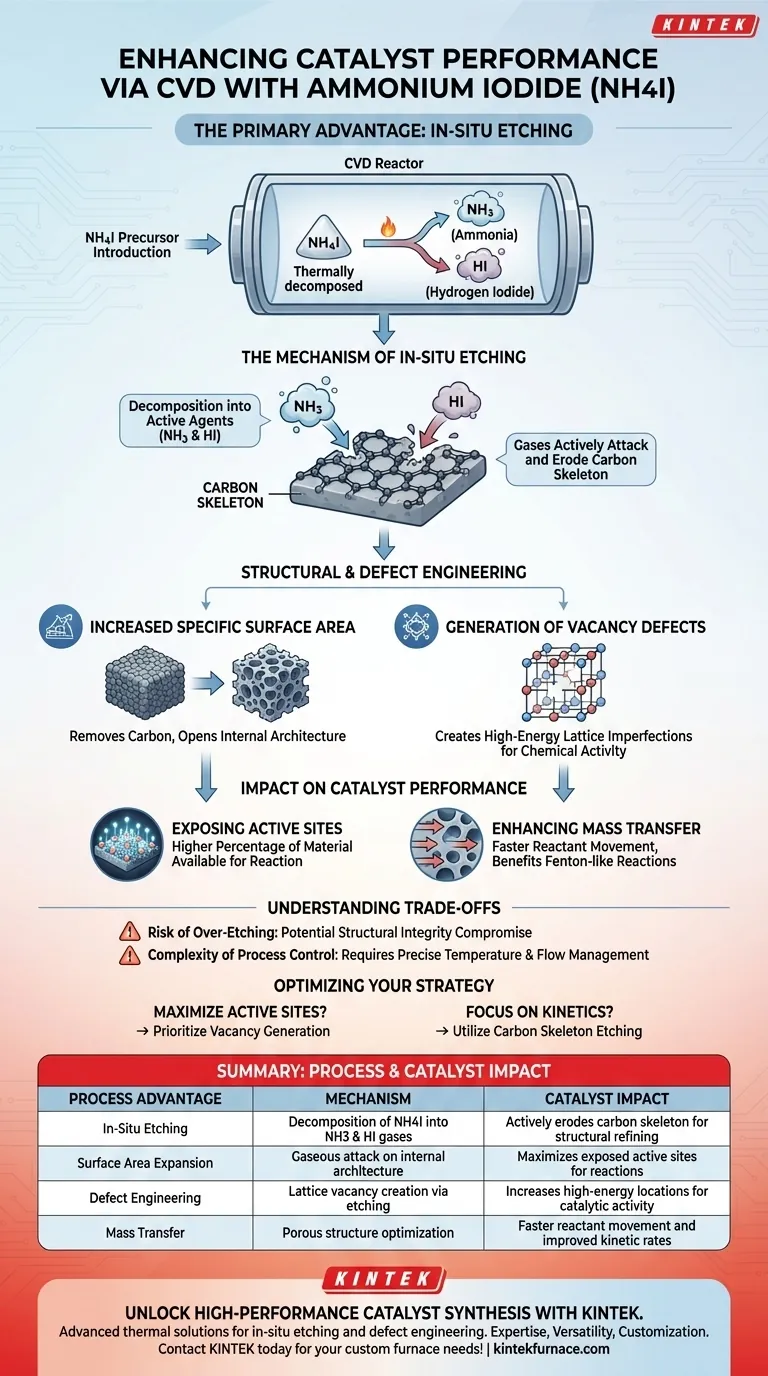

The primary process advantage of utilizing a Chemical Vapor Deposition (CVD) system with ammonium iodide (NH4I) is the generation of in-situ etching agents.

By facilitating the thermal decomposition of NH4I, the system produces ammonia (NH3) and hydrogen iodide (HI). These gases actively etch the catalyst's carbon skeleton, fundamentally altering its physical structure to enhance performance in Fenton-like reactions.

By decomposing ammonium iodide into ammonia and hydrogen iodide, the CVD process chemically etches the carbon skeleton. This increases specific surface area and creates vacancy defects, resulting in improved mass transfer and higher catalytic activity.

The Mechanism of In-Situ Etching

Decomposition into Active Agents

The CVD environment triggers the decomposition of ammonium iodide. This reaction releases two distinct gases: ammonia (NH3) and hydrogen iodide (HI).

Targeting the Carbon Skeleton

These gases function as potent in-situ etching agents. Rather than simply depositing material, they actively attack and erode specific portions of the catalyst's carbon skeleton during the synthesis process.

Structural and Defect Engineering

Increasing Specific Surface Area

The primary physical result of this gaseous etching is a significant increase in the specific surface area of the catalyst. By removing carbon material, the process opens the internal architecture of the material.

Generating Vacancy Defects

Simultaneously, the etching process introduces vacancy defects within the lattice. These defects are not errors; they are deliberate structural imperfections that serve as high-energy locations for chemical activity.

Impact on Catalyst Performance

Exposing Active Sites

The combination of increased surface area and defect generation exposes a higher number of active sites. This ensures that a larger percentage of the catalyst material is available to participate in the reaction.

Enhancing Mass Transfer

The porous, etched structure allows reactants to move more freely through the material. This leads to a significant enhancement in mass transfer efficiency, specifically benefiting Fenton-like catalytic reactions.

Understanding the Trade-offs

Risk of Over-Etching

While etching increases surface area, it is a subtractive process. Improper control of the CVD parameters could lead to over-etching, potentially compromising the structural integrity of the carbon skeleton.

Complexity of Process Control

Using CVD to generate reactive gases like HI requires precise management of temperature and flow rates. This introduces a higher level of operational complexity compared to simple wet-chemical doping methods.

Optimizing Your Catalyst Synthesis Strategy

When deciding if this CVD method matches your engineering goals, consider your specific requirements for catalyst architecture.

- If your primary focus is maximizing active sites: Prioritize this method for its ability to generate vacancy defects through the aggressive action of HI and NH3.

- If your primary focus is reaction kinetics: Utilize this approach to etch the carbon skeleton, which directly improves mass transfer efficiency for faster reaction rates.

This method transforms ammonium iodide from a simple precursor into a dual-purpose tool for structural refining and defect engineering.

Summary Table:

| Process Advantage | Mechanism | Catalyst Impact |

|---|---|---|

| In-Situ Etching | Decomposition of NH4I into NH3 & HI gases | Actively erodes carbon skeleton for structural refining |

| Surface Area Expansion | Gaseous attack on internal architecture | Maximizes exposed active sites for reactions |

| Defect Engineering | Lattice vacancy creation via etching | Increases high-energy locations for catalytic activity |

| Mass Transfer | Porous structure optimization | Faster reactant movement and improved kinetic rates |

Unlock High-Performance Catalyst Synthesis with KINTEK

Take control of your catalyst engineering with KINTEK’s advanced thermal solutions. Whether you are performing in-situ etching or precise defect engineering, our CVD systems provide the temperature stability and gas flow control necessary to transform precursors like NH4I into high-activity catalysts.

Why partner with KINTEK?

- Expertise: Backed by industry-leading R&D and manufacturing.

- Versatility: We offer Muffle, Tube, Rotary, Vacuum, and CVD systems tailored for lab and industrial use.

- Customization: Fully adaptable systems to meet your unique chemical process requirements.

Ready to enhance your material properties and mass transfer efficiency? Contact KINTEK today to discuss your custom furnace needs!

Visual Guide

References

- Junjun Pei, Jinming Luo. Non-metallic iodine single-atom catalysts with optimized electronic structures for efficient Fenton-like reactions. DOI: 10.1038/s41467-025-56246-6

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- MPCVD Machine System Reactor Bell-jar Resonator for Lab and Diamond Growth

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

People Also Ask

- Why are high operating temperatures a disadvantage for CVD? Limiting Substrate Choices and Increasing Defects

- What types of materials are most suitable for PVD and CVD? Optimize Your Thin Film Deposition Choices

- What factors should be considered when choosing between PVD and CVD? Optimize Your Coating Process for Better Results

- Why is ultrasonic cleaning of Si/SiO2 substrates required before MoS2 growth? Ensure High-Quality CVD Results

- Why are high-purity hydrogen and argon necessary for hBN thin film LPCVD? Master Gas Roles for Superior Growth

- What is the working principle of Chemical Vapor Deposition (CVD)? Master Thin Film Growth for Superior Coatings

- What are the main advantages of Chemical Vapor Deposition (CVD)? Unlock High-Performance Thin Films

- What are the key components of a CVD system? Master Thin Film Deposition for Your Lab