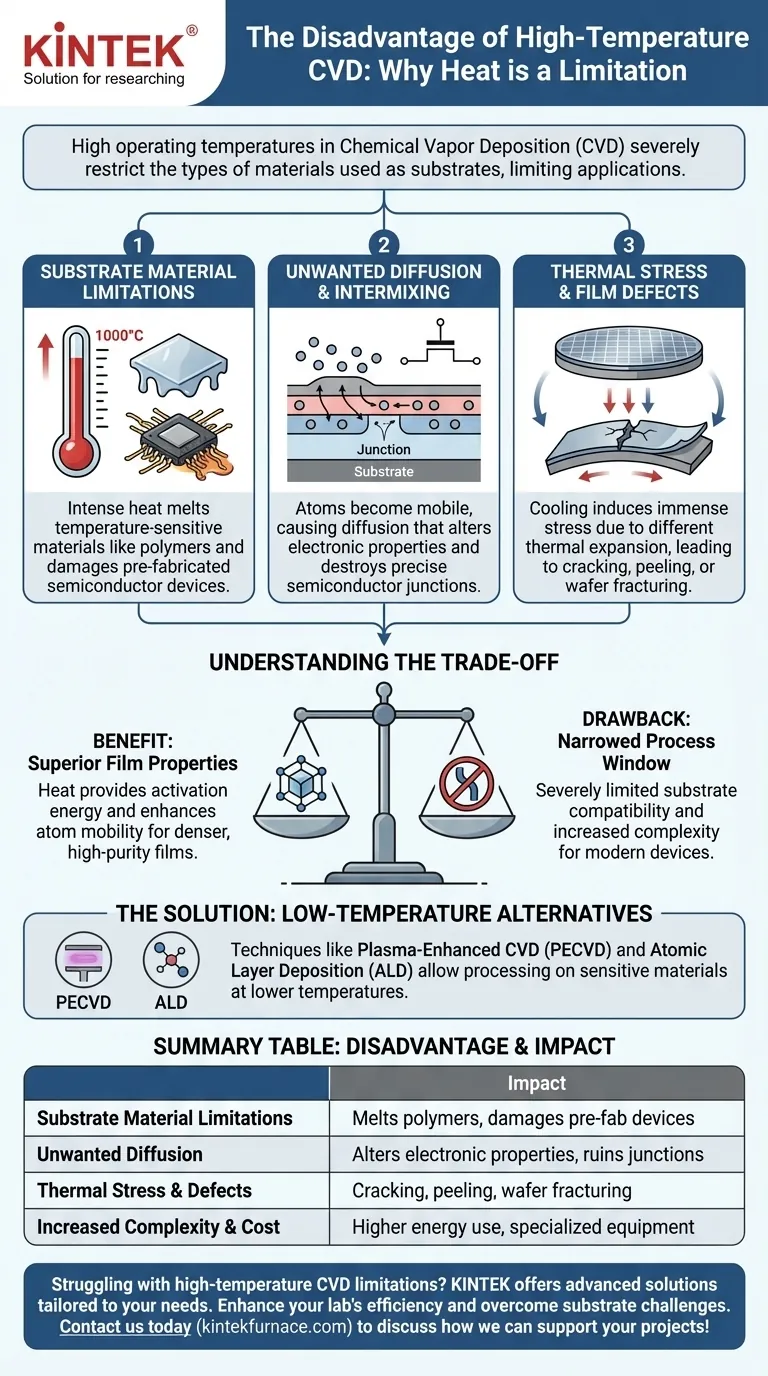

High operating temperatures in Chemical Vapor Deposition (CVD) are a primary disadvantage because they severely restrict the types of materials that can be used as substrates. The intense heat required for the chemical reactions can melt, decompose, or otherwise damage temperature-sensitive materials, such as polymers or semiconductor devices that have already been partially fabricated.

While heat is essential to drive the chemical reactions that form high-quality films in CVD, this same thermal energy is also its greatest limitation. It narrows the range of compatible materials, can compromise the integrity of the final device, and increases process complexity and cost.

The Role of Temperature in CVD

To understand the disadvantages of heat, we must first understand why it is necessary. High temperature provides the energy needed for the deposition process to occur effectively.

Providing Activation Energy

CVD is fundamentally a chemical process. Precursor gases must be broken apart and react to form the desired solid film, and these reactions require a significant amount of energy—known as activation energy—which is typically supplied by heating the substrate to several hundred or even over a thousand degrees Celsius.

Enhancing Film Quality

Heat also gives atoms that land on the substrate surface enough mobility to move around and find their ideal positions in the crystal lattice. This results in denser, more uniform, and higher-purity films.

Key Disadvantages of High-Temperature Operation

The requirement for high thermal energy creates several significant, practical challenges that limit the application of traditional CVD.

Substrate Material Limitations

This is the most direct and common drawback. Many advanced applications involve depositing films onto materials that cannot withstand high temperatures.

For example, flexible electronics often use polymer substrates that would melt or deform at typical CVD temperatures. Similarly, depositing a layer onto a complex microchip with pre-existing metallic interconnects is often impossible, as the heat could destroy those components.

Unwanted Diffusion and Intermixing

Atoms become much more mobile at high temperatures. This can cause atoms from the substrate to diffuse into the growing film, or atoms from the film to diffuse into the substrate.

In semiconductor manufacturing, this is a critical failure point. Unwanted dopant diffusion can shift or destroy the precise electronic junctions that make a transistor work, rendering the device useless.

Thermal Stress and Film Defects

When the deposition is complete and the system cools down, the newly grown film and the underlying substrate contract. If they have different coefficients of thermal expansion, this mismatch induces immense stress.

High deposition temperatures magnify this effect, leading to defects such as film cracking, peeling, or even bowing and fracturing of the entire wafer.

Understanding the Trade-offs

The choice to use high-temperature CVD is a classic engineering trade-off between film quality and process compatibility. There is no single "best" approach; the right choice depends entirely on the goal.

The Benefit of Heat: Superior Film Properties

For applications where film purity and crystallinity are paramount, and the substrate can handle the heat (e.g., growing silicon epitaxy on a bare silicon wafer), high-temperature CVD is often the superior method. The resulting films are of exceptionally high quality.

The Drawback: A Narrowed Process Window

The cost of that quality is a severely restricted process window. The high-temperature requirement immediately disqualifies a vast range of substrates and integrated device structures that are critical for modern technology.

The Solution: Low-Temperature Alternatives

To overcome these limitations, techniques like Plasma-Enhanced CVD (PECVD) were developed. PECVD uses energy from a plasma to help break apart precursor gases, allowing deposition to occur at much lower temperatures. This opens the door to processing on plastics, assembled devices, and other sensitive materials, though often with a trade-off in film density or purity.

Making the Right Choice for Your Goal

Selecting a deposition method requires balancing the need for ideal film properties against the thermal constraints of your substrate.

- If your primary focus is the highest possible film crystallinity on a robust substrate: Conventional high-temperature CVD is often the most effective choice.

- If you are working with temperature-sensitive materials like polymers or pre-fabricated devices: You must use a low-temperature technique like PECVD or Atomic Layer Deposition (ALD).

- If your goal is to minimize thermal stress and prevent dopant diffusion: Lowering the deposition temperature is a critical requirement, forcing a move away from traditional thermal CVD.

Ultimately, understanding the thermal budget of your entire device is the key to selecting the correct deposition strategy.

Summary Table:

| Disadvantage | Impact |

|---|---|

| Substrate Material Limitations | Melts or damages polymers and pre-fabricated devices |

| Unwanted Diffusion and Intermixing | Alters electronic properties, ruining semiconductor junctions |

| Thermal Stress and Film Defects | Leads to cracking, peeling, or wafer fracturing |

| Increased Process Complexity and Cost | Higher energy use and need for specialized equipment |

Struggling with high-temperature CVD limitations? KINTEK offers advanced solutions tailored to your needs. Leveraging exceptional R&D and in-house manufacturing, we provide high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, with deep customization to meet unique experimental requirements. Enhance your lab's efficiency and overcome substrate challenges—contact us today to discuss how we can support your projects!

Visual Guide

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- Why is the tube design important in CVD furnaces? Ensure Uniform Deposition for High-Quality Films

- What role do CVD tube furnace sintering systems play in 2D material synthesis? Enabling High-Quality Atomic Layer Growth

- What temperature ranges can a CVD Tube Furnace achieve with different tube materials? Unlock High-Temp Precision for Your Lab

- Which industries and research fields benefit from CVD tube furnace sintering systems for 2D materials? Unlock Next-Gen Tech Innovations

- What types of atmosphere control does a CVD Tube Furnace support? Master Vacuum and Gas Control for Precision