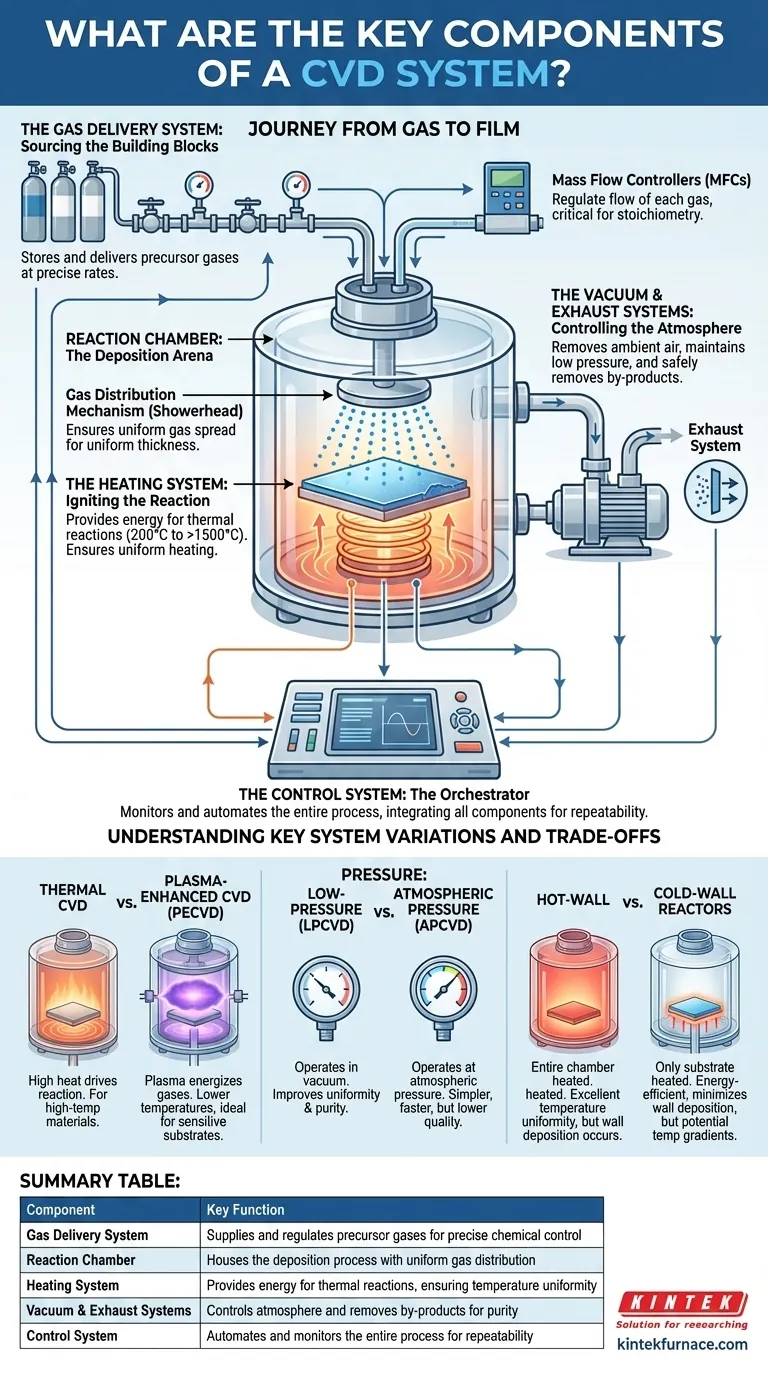

At its core, a Chemical Vapor Deposition (CVD) system is an integrated set of components designed to create a highly controlled environment for growing thin films. Every CVD system, regardless of its specific type, combines five fundamental subsystems: a gas delivery system to supply the chemical precursors, a reaction chamber to house the process, a heating mechanism to provide energy, a vacuum system to control the atmosphere, and a control system to orchestrate the entire operation.

A CVD system is not merely a collection of hardware; it is an instrument for precisely manipulating gas, temperature, and pressure. Understanding how each component governs these variables is the key to controlling the deposition process and achieving the desired film properties.

The Journey from Gas to Film: A Component-by-Component Breakdown

To understand how a CVD system functions, it's best to follow the process from start to finish. Precursor gases are introduced, energized into a reactive state, and deposited onto a substrate, with all waste carefully removed.

The Gas Delivery System: Sourcing the Building Blocks

The entire process begins with the precursors—the chemical "building blocks" of the final film. The gas delivery system is responsible for storing these materials and delivering them to the reaction chamber at an extremely precise and stable rate.

This system uses Mass Flow Controllers (MFCs) to regulate the flow of each gas. The ability to precisely control the gas mixture is critical, as it directly influences the chemistry of the reaction and the stoichiometry of the resulting film.

The Reaction Chamber: The Deposition Arena

The reaction chamber is the heart of the system where the deposition takes place. These chambers are typically made of materials like quartz or stainless steel that can withstand high temperatures and reactive chemical environments without contaminating the process.

Inside the chamber, a gas distribution mechanism, often a "showerhead," ensures the precursor gases are spread evenly over the surface of the substrate. This is essential for achieving a film with uniform thickness.

The Heating System: Igniting the Reaction

Most CVD processes are thermally driven, requiring significant energy to initiate the chemical reactions. The heating system is responsible for bringing the substrate, and sometimes the entire chamber, to the target temperature.

Temperatures can range from a relatively low 200°C for some processes to over 1500°C for materials like silicon carbide or diamond. Uniform heating across the substrate is paramount to ensure consistent film properties.

The Vacuum & Exhaust Systems: Controlling the Atmosphere

The vacuum system, composed of one or more pumps, serves two primary purposes. First, it removes ambient air to create a pure environment, preventing unwanted reactions with oxygen or nitrogen. Second, it maintains the process at a specific, often low, pressure.

The exhaust system works in concert with the vacuum pumps to safely remove unreacted precursor gases and hazardous chemical by-products from the chamber.

The Control System: The Orchestrator

The control system is the central brain that monitors and automates the entire process. It integrates all other components, managing gas flow rates from the MFCs, adjusting power to the heating system, and maintaining chamber pressure. This ensures the process is repeatable and reliable from one run to the next.

Understanding Key System Variations and Trade-offs

While all CVD systems share the components above, their specific configuration creates critical trade-offs in performance, cost, and capability. The "best" system is defined by the specific requirements of the film being deposited.

Thermal CVD vs. Plasma-Enhanced CVD (PECVD)

The primary trade-off here is temperature. A standard thermal CVD process uses high heat alone to drive the reaction. Plasma-Enhanced CVD (PECVD) adds a power source to generate a plasma within the chamber.

This plasma energizes the precursor gases, allowing the chemical reaction to occur at a much lower temperature. This makes PECVD essential for depositing films onto temperature-sensitive substrates like plastics or pre-processed semiconductor wafers.

Pressure: Low-Pressure (LPCVD) vs. Atmospheric Pressure (APCVD)

Another key variable is operating pressure. Low-Pressure CVD (LPCVD) systems operate in a vacuum, which reduces unwanted gas-phase reactions and improves the uniformity and purity of the film.

Atmospheric Pressure CVD (APCVD), as the name implies, operates at normal atmospheric pressure. These systems are simpler, faster, and cheaper but typically produce films of lower quality and uniformity compared to LPCVD.

Hot-Wall vs. Cold-Wall Reactors

This describes how the chamber is heated. In a hot-wall reactor, the entire chamber tube is heated, which provides excellent temperature uniformity for multiple substrates. The downside is that deposition occurs on the chamber walls, consuming precursors and requiring frequent cleaning.

In a cold-wall reactor, only the substrate holder is heated. This is more energy-efficient and minimizes wall deposition, but it can create temperature gradients and gas convection currents that may affect film uniformity.

Matching the System to Your Deposition Goal

The choice of CVD system configuration is dictated entirely by the desired outcome. There is no single "best" setup; there is only the right tool for the job.

- If your primary focus is high-purity, uniform films for semiconductors: An LPCVD or Ultra-High Vacuum CVD (UHVCVD) system with precise mass flow and cold-wall heating is the standard.

- If your primary focus is depositing on temperature-sensitive substrates: A PECVD system is the necessary choice to enable deposition at significantly lower temperatures.

- If your primary focus is high-throughput, industrial-scale coating: An APCVD system, often configured for continuous processing, is likely the most cost-effective and efficient solution.

Understanding how these core components and their configurations control the fundamental process variables empowers you to select or design a CVD system that precisely meets your material fabrication needs.

Summary Table:

| Component | Key Function |

|---|---|

| Gas Delivery System | Supplies and regulates precursor gases for precise chemical control |

| Reaction Chamber | Houses the deposition process with uniform gas distribution |

| Heating System | Provides energy for thermal reactions, ensuring temperature uniformity |

| Vacuum & Exhaust Systems | Controls atmosphere and removes by-products for purity |

| Control System | Automates and monitors the entire process for repeatability |

Ready to enhance your lab's capabilities with a tailored CVD system? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements for thin film deposition. Contact us today to discuss how we can optimize your process and deliver superior results!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- How does a CVD system precisely control InN nanowire growth? Expert Secrets to High-Quality Synthesis

- What role does an industrial-grade CVD system play in Ni-Based Superalloys? Enhancing Durability via Precise Coating

- What are the two main methods of synthetic diamond production? Discover HPHT vs. CVD for Lab-Grown Gems

- What are the advantages of these CVD systems compared to conventional CVD? Unlock Lower Temperatures and Faster Processing

- What is the use of CVD machine? Transform Surfaces with Atomic-Level Precision

- What are the industrial applications of CVD systems? Unlock High-Performance Thin Films for Your Industry

- Why is precise control of carrier gas flow rates critical for TB-MoS2 yield? Master Kinetic Growth in CVD Systems

- How does the flexibility of CVD furnaces benefit thin film preparation? Achieve Precise Atomic-Level Engineering