High-purity hydrogen and argon serve distinct, non-negotiable roles in the Low-Pressure Chemical Vapor Deposition (LPCVD) of hexagonal boron nitride (hBN). Argon provides a strictly inert environment for transporting chemical precursors, while hydrogen acts as an active chemical agent to reduce oxides, regulate growth speed, and protect the film during thermal transitions.

The success of hBN thin film preparation relies on the synergy between these two gases: Argon acts as the physical vehicle for transport, while Hydrogen chemically conditions the substrate and safeguards the material from oxidation during annealing and cooling.

The Role of Argon: The Inert Transporter

Establishing a Clean Environment

Argon is primarily used to establish a protective, inert atmosphere within the reaction chamber. Because it is chemically non-reactive, it displaces atmospheric gases without interfering with the delicate nucleation process of the hBN.

Carrier Functionality

Beyond protection, Argon acts as the carrier gas. It is responsible for physically transporting the specific precursors required for hBN growth into the reaction zone, ensuring a steady and uniform supply of material to the substrate.

The Role of Hydrogen: The Chemical Modulator

Substrate Annealing and Preparation

Before the actual growth phase begins, hydrogen is introduced to anneal the substrate. This step effectively strips away surface oxides that would otherwise contaminate the interface.

Additionally, this hydrogen treatment helps increase the grain size of the substrate. A cleaner, larger-grain substrate surface is critical for promoting high-quality epitaxial growth of the hBN film.

Regulating Reaction Kinetics

During the deposition phase, hydrogen participates directly in the chemical reaction dynamics. It helps regulate the kinetics of the growth, ensuring the hBN forms at a controlled rate rather than precipitating chaotically.

Protection During High-Temperature Cooling

The risk of damage continues even after the deposition is complete. Hydrogen flow must be maintained during the cooling stage to prevent oxidation. This protects both the newly formed hBN thin films and the metal electrodes from degrading as they cool down from high process temperatures.

Understanding the Trade-offs

The Necessity of High Purity

The requirement for "high-purity" gas is not a suggestion; it is a constraint of the LPCVD process. Any impurities in the carrier gases, particularly residual oxygen or moisture, will immediately compromise the "reductive atmosphere" established by the hydrogen.

Balancing Gas Ratios

While Hydrogen is essential for reduction and protection, its ratio relative to Argon must be carefully managed. Insufficient hydrogen leads to oxidation and poor grain quality, while the primary function of Argon is required to maintain efficient mass transport of precursors.

Optimizing Your Gas Strategy

To ensure high-quality hBN thin films, tailor your gas usage to the specific phase of the LPCVD cycle:

- If your primary focus is substrate quality: Ensure a dedicated hydrogen annealing phase prior to growth to maximize grain size and remove pre-existing oxides.

- If your primary focus is film uniformity: Rely on high-purity Argon flow to maintain steady precursor transport without introducing chemical variances.

- If your primary focus is preventing post-growth defects: Maintain hydrogen flow throughout the entire cooling process to shield the film and electrodes from oxidation.

Precise control over these two gases is the difference between a contaminated sample and a device-grade semiconductor film.

Summary Table:

| Gas Type | Primary Function | Role in Process Phase |

|---|---|---|

| Argon (Ar) | Inert Carrier | Transports precursors and maintains an oxygen-free chamber environment. |

| Hydrogen (H2) | Chemical Modulator | Anneals substrates, regulates reaction kinetics, and prevents cooling oxidation. |

| H2/Ar Mixture | Synergy | Balances physical transport with chemical reduction for high-quality film growth. |

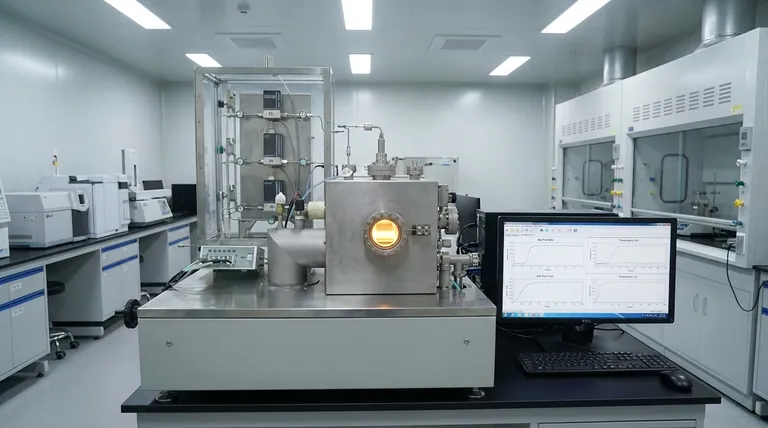

Elevate Your Thin Film Synthesis with KINTEK

Precision in gas control requires equipment that can handle demanding LPCVD environments. KINTEK provides high-performance Muffle, Tube, and Vacuum systems specifically designed for high-temperature semiconductor research.

Backed by expert R&D and manufacturing, our systems are fully customizable to support your unique hBN growth protocols, ensuring the purity and thermal stability your lab requires.

Ready to optimize your thin film deposition? Contact us today to discuss your custom furnace needs with our engineering team!

References

- Sibo Wang, Zhanguo Chen. Transfer-Free Analog and Digital Flexible Memristors Based on Boron Nitride Films. DOI: 10.3390/nano14040327

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Magnesium Extraction and Purification Condensing Tube Furnace

People Also Ask

- What are the general reactions for metal and ceramic deposition in CVD? Master Key Processes for Superior Thin Films

- What is the key difference between PVD and CVD? Choose the Best Coating Method for Your Needs

- How does the ALD process ensure effective passivation on WS2 surfaces? Achieve Superior Dielectric Integrity

- Why are copper films preferred over aluminum in some electronic applications? Discover Key Advantages for High-Performance ICs

- What is the pressure range and vacuum capability of the CVD systems? Optimize Your Material Growth with Precise Control

- How do sapphire and silicon dioxide substrates differ in CVD growth of VSe2? Choose the Right Growth Surface

- What are the advantages of using CVD? Achieve High-Purity, Conformal Thin Films for Your Applications

- What are the advantages of using a CVD system? Achieve Precision and Uniformity for Complex Thin Films