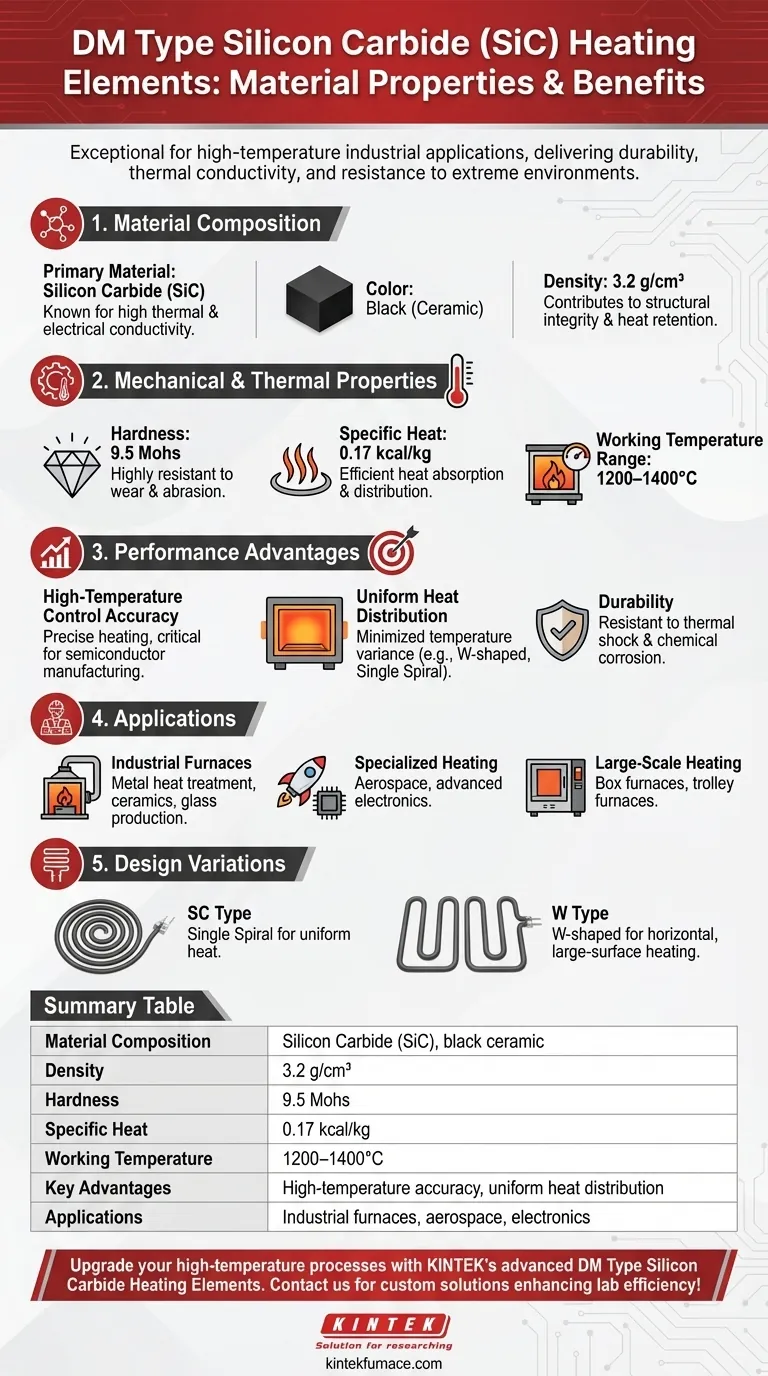

Silicon Carbide (SiC) heating elements, particularly the DM Type, are widely used in high-temperature industrial applications due to their exceptional material properties. These elements are known for their durability, high thermal conductivity, and resistance to extreme temperatures, making them ideal for use in atmosphere retort furnaces and other demanding environments. The material properties include high density, hardness, and specific heat, which contribute to their performance in consistent and uniform heating applications.

Key Points Explained:

-

Material Composition

- Silicon Carbide (SiC): The primary material, known for its high thermal and electrical conductivity.

- Color: Typically black, indicative of its ceramic nature.

- Density: 3.2 g/cm³, contributing to structural integrity and heat retention.

-

Mechanical and Thermal Properties

- Hardness: 9.5 Mohs, making it highly resistant to wear and abrasion.

- Specific Heat: 0.17 kcal/kg, allowing efficient heat absorption and distribution.

- Working Temperature Range: 1200–1400°C, suitable for high-temperature industrial processes.

-

Performance Advantages

- High-Temperature Control Accuracy: Ensures precise heating, critical for applications like semiconductor manufacturing.

- Uniform Heat Distribution: Achieved through designs like the W-shaped or Single Spiral configurations, minimizing temperature variance.

- Durability: Resistant to thermal shock and chemical corrosion, ideal for harsh environments.

-

Applications

- Industrial Furnaces: Used in metal heat treatment, ceramics, and glass production.

- Specialized Heating: Aerospace and advanced electronics manufacturing due to automated temperature adjustment capabilities.

- Large-Scale Heating: Effective in box furnaces and trolley furnaces where spatial uniformity is crucial.

-

Design Variations

- SC Type: Single Spiral design for uniform heat distribution.

- W Type: W-shaped configuration for horizontal installation and large-surface heating.

These properties make DM Type Silicon Carbide Heating Elements a reliable choice for high-performance heating systems, particularly in industries requiring precision and durability.

Summary Table:

| Property | Value/Description |

|---|---|

| Material Composition | Silicon Carbide (SiC), black ceramic |

| Density | 3.2 g/cm³ |

| Hardness | 9.5 Mohs |

| Specific Heat | 0.17 kcal/kg |

| Working Temperature | 1200–1400°C |

| Key Advantages | High-temperature accuracy, uniform heat distribution |

| Applications | Industrial furnaces, aerospace, electronics |

Upgrade your high-temperature processes with KINTEK's advanced DM Type Silicon Carbide Heating Elements. Leveraging our exceptional R&D and in-house manufacturing, we deliver precision heating solutions tailored to your unique requirements. Whether you need uniform heat distribution for industrial furnaces or durable elements for aerospace applications, our products—including Muffle Furnaces, Tube Furnaces, and CVD/PECVD Systems—are designed for excellence. Contact us today to discuss how we can enhance your lab's efficiency with custom SiC heating solutions!

Products You Might Be Looking For:

High-temperature observation windows for vacuum systems Precision vacuum electrode feedthroughs Molybdenum disilicide heating elements for electric furnaces Stainless steel vacuum ball valves KF flange observation windows for ultra-high vacuum

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- Why are SiC heating elements considered environmentally friendly? Discover Their Eco-Efficiency & Lifespan Insights

- What are the properties and capabilities of Silicon Carbide (SiC) as a heating element? Unlock Extreme Heat and Durability

- Why is silicon carbide resistant to chemical reactions in industrial furnaces? Unlock Durable High-Temp Solutions

- Why are SIC heating elements resistant to chemical corrosion? Discover the Self-Protecting Mechanism

- What are the properties and applications of silicon carbide (SiC)? Unlock High-Temperature Performance