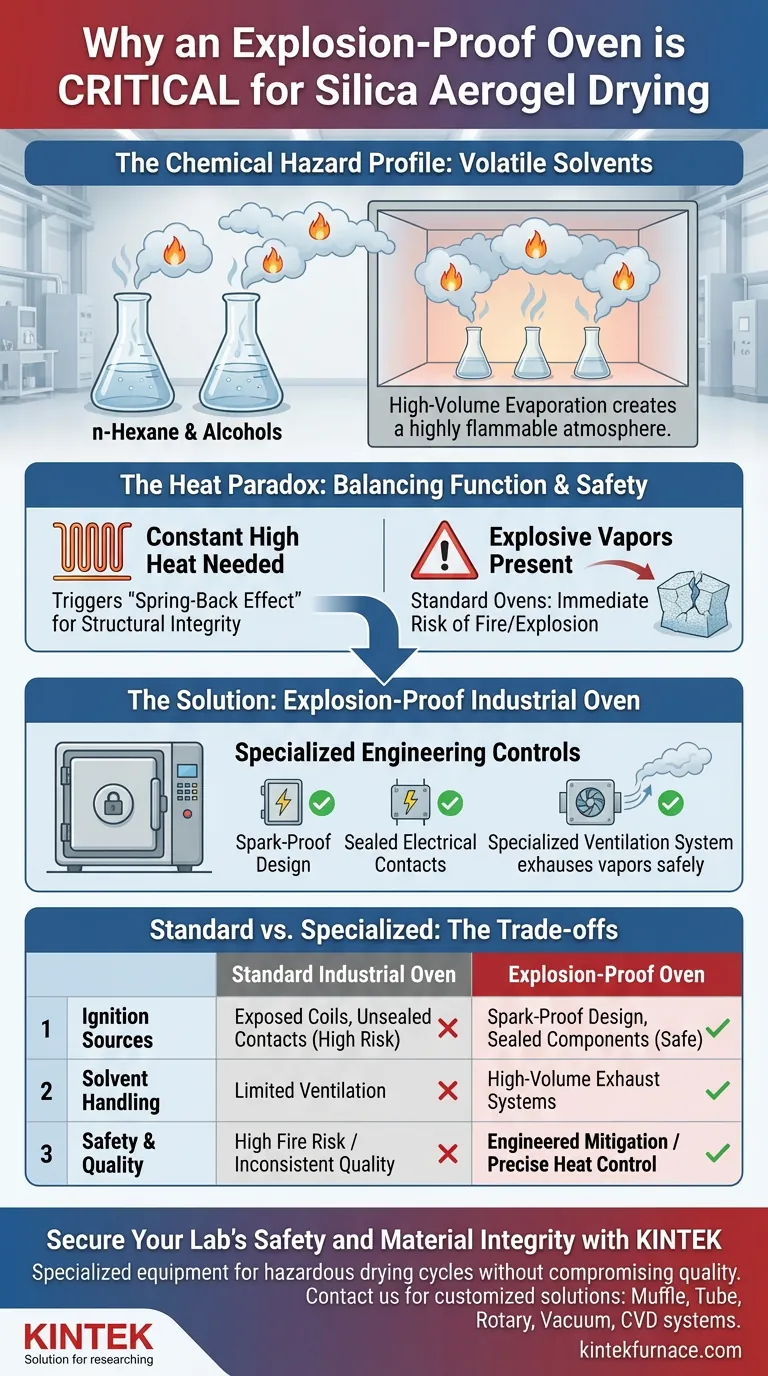

The critical necessity of an explosion-proof oven is dictated by the chemical volatility involved in the drying process. Drying hydrophobically modified silica aerogels requires the evaporation of large quantities of flammable organic solvents, such as n-hexane and residual alcohols. Using a standard oven would expose these concentrated, combustible vapors to heating elements, creating an immediate and high risk of fire or explosion.

The drying process presents a dual challenge: maintaining the high temperatures required for the aerogel's structural integrity while simultaneously managing a hazardous atmosphere of flammable solvent vapors.

The Chemical Hazard Profile

Managing Volatile Organic Solvents

The fundamental risk factor in this process is the solvent burden. To produce these aerogels, the wet gel structure is saturated with organic compounds like n-hexane and alcohols.

High-Volume Evaporation

As the drying cycle progresses, these solvents do not merely seep out; they evaporate into the oven chamber. This rapidly creates a highly flammable atmosphere that standard ventilation systems cannot safely handle.

The Role of Temperature in Processing

Triggering the Spring-Back Effect

Heat is not applied solely to remove moisture; it is a functional requirement for the material's structure. The primary reference notes that a constant high-temperature environment is essential to achieve the "spring-back effect."

Balancing Heat and Safety

This creates a paradox: you must apply significant heat to a substance that is releasing explosive gas. An explosion-proof oven solves this by providing precise temperature control to facilitate the spring-back mechanism without becoming an ignition source.

Understanding the Trade-offs: Standard vs. Specialized Equipment

The Risk of Standard Components

Standard industrial ovens typically contain exposed heating coils, unsealed electrical contacts, or fans that can generate sparks. In an atmosphere rich with n-hexane vapor, a single spark is sufficient to cause a catastrophe.

Specialized Mitigation Features

Explosion-proof ovens utilize distinct engineering controls to mitigate this risk. As highlighted in the primary reference, they feature specialized ventilation systems and spark-proof designs specifically engineered to exhaust solvent vapors safely before they reach explosive concentrations.

Making the Right Choice for Your Goal

Ensuring the successful production of silica aerogels requires prioritizing both personnel safety and material quality.

- If your primary focus is Safety Compliance: You must verify that the oven's explosion-proof rating matches the specific volatility profile of n-hexane and the alcohols used.

- If your primary focus is Material Quality: You must ensure the oven maintains the precise, constant high temperatures required to trigger the spring-back effect, preventing structural collapse.

Ultimately, the explosion-proof oven is not just a safety device; it is the only enabling technology that allows for the high-temperature processing of these volatile materials.

Summary Table:

| Feature | Standard Industrial Oven | Explosion-Proof Oven |

|---|---|---|

| Ignition Sources | Exposed heating coils & unsealed contacts | Spark-proof design & sealed components |

| Solvent Handling | Limited ventilation for flammable vapors | High-volume specialized exhaust systems |

| Safety Risk | High risk of fire/explosion with organic solvents | Engineered to mitigate volatile atmospheres |

| Aerogel Quality | Inconsistent temp control risks collapse | Precise heat for optimal 'spring-back' effect |

Secure Your Lab’s Safety and Material Integrity with KINTEK

Processing silica aerogels requires more than just heat—it demands a sophisticated environment where safety meets precision. KINTEK provides the specialized equipment needed to handle hazardous drying cycles without compromising on quality.

Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, alongside lab high-temperature furnaces that are fully customizable to your specific solvent profiles and material needs. Don't risk a catastrophe with standard equipment; let our experts help you select or design the perfect system for your application.

Contact KINTEK today for a customized solution!

Visual Guide

References

- Jinjing Guo, Baohua Guo. Enhancing Mesopore Volume and Thermal Insulation of Silica Aerogel via Ambient Pressure Drying-Assisted Foaming Method. DOI: 10.3390/ma17112641

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1200℃ Muffle Oven Furnace for Laboratory

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- Spark Plasma Sintering SPS Furnace

People Also Ask

- How are muffle furnaces used in forensic investigations? Uncover Hidden Evidence with Precision Ashing

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- What is the function of a high-temperature box resistance furnace? Optimize Hierarchical Zeolite Synthesis

- Why is the muffle furnace widely used in the industrial sector? Achieve Clean, Precise High-Temperature Processing

- What is a batch furnace? Maximize Flexibility and Precision for Your Heat Treatment

- What is the main drawback of muffle furnaces regarding inert gas dispersion? Learn How to Ensure Uniform Atmosphere

- What temperature ranges can different muffle furnace types achieve? Find the Perfect Fit for Your Lab

- What are some common applications of muffle furnaces in high-temperature processes? Discover Precision Heating Solutions