In industrial heat treatment, a batch furnace is a system designed to process materials one distinct load, or "batch," at a time. Unlike continuous systems where materials constantly flow through, a batch furnace treats a single, specific group of parts through an entire thermal cycle before the next group is introduced. Even complex models with multiple chambers, such as for heating and cooling, still process one integral batch at a time.

The defining characteristic of a batch furnace is not simply processing one load at a time, but the exceptional process flexibility and precision this method affords. It allows for a unique, customized thermal recipe for every single batch that enters the system.

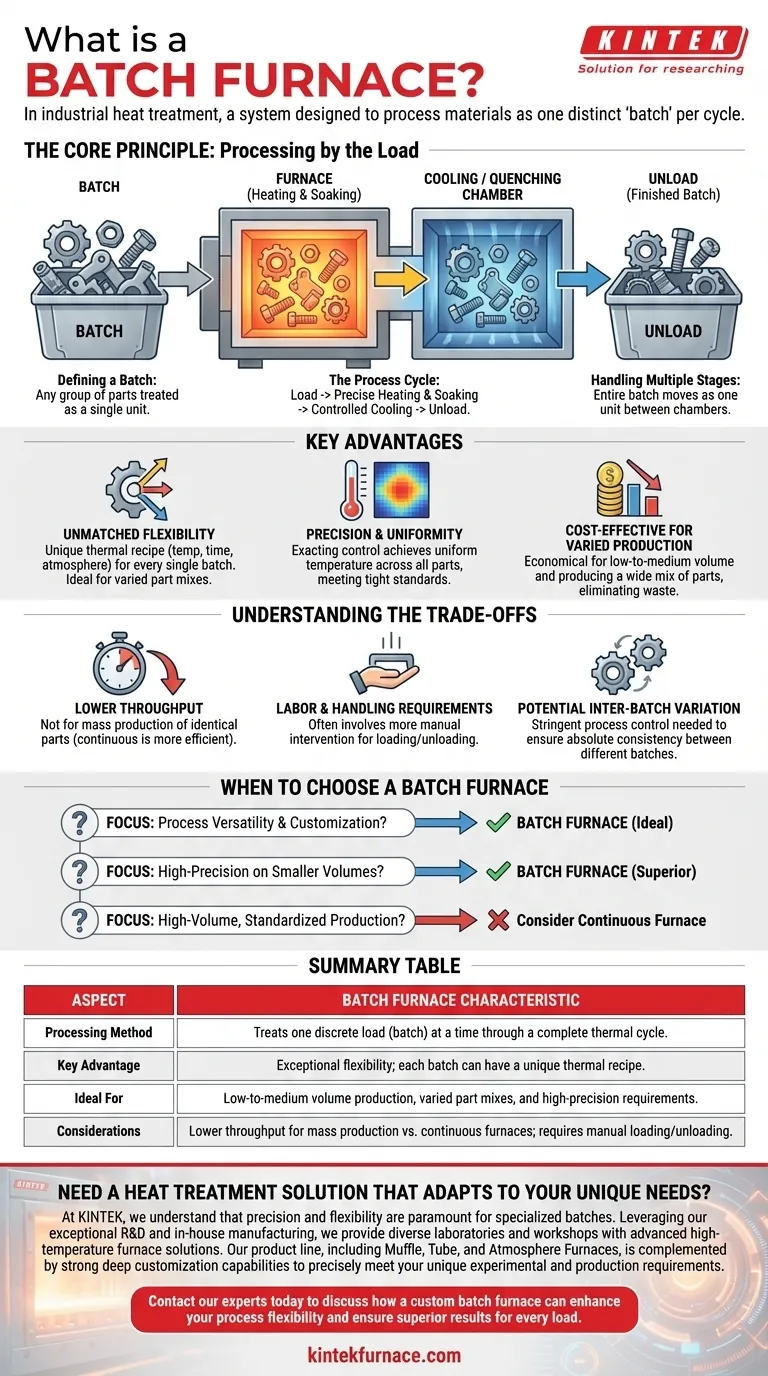

The Core Principle: Processing by the Load

The batch furnace operates on a simple, powerful principle: treating a discrete quantity of material as a single unit throughout the entire heat treatment process.

Defining a "Batch"

A batch is any group of parts loaded into the furnace together. This could range from a handful of large components to thousands of small fasteners, all treated with the same thermal profile.

The Process Cycle

A typical cycle involves loading the batch, executing a precise heating and soaking program, followed by a controlled cooling or quenching sequence. The entire furnace is dedicated to that single batch until the cycle is complete and the parts are unloaded.

Handling Multiple Stages

Some advanced batch furnaces, like sealed quench furnaces, have separate chambers for heating and cooling. However, the principle remains the same: the entire batch moves as a single unit from the heating chamber to the cooling chamber, maintaining its integrity as one load.

Key Advantages of the Batch Approach

The decision to use a batch furnace is driven by its unique benefits, which are essential for many manufacturing and metallurgical applications.

Unmatched Process Flexibility

Because each cycle is independent, every batch can receive a completely different treatment. This allows you to change temperature, time, and atmosphere from one load to the next, making it perfect for shops that handle varying part sizes, material grades, and heat treatment specifications.

Precision and Uniformity

Batch furnaces offer exacting control over heating and cooling rates. By treating a static load within a contained environment, it is easier to achieve uniform temperature across all parts in the batch, which is critical for meeting tight metallurgical standards.

Cost-Effectiveness for Varied Production

For low-to-medium volume production or for producing a wide mix of different parts, a batch furnace is highly economical. It eliminates the high operational cost and energy waste of running a large, continuous system for a small or non-standard job.

Understanding the Trade-offs

While powerful, the batch furnace is not the universal solution. Understanding its limitations is key to making an informed decision.

Lower Throughput for Mass Production

The primary trade-off is production volume. For manufacturing a high volume of identical parts, a continuous furnace that processes material in a non-stop flow is almost always more efficient and cost-effective.

Labor and Handling Requirements

Batch processing often involves more manual intervention for loading and unloading compared to fully automated continuous lines. This can translate to higher labor costs and dependency on operator scheduling.

Potential for Inter-Batch Variation

While uniformity within a single batch is excellent, slight variations can occur between different batches if process parameters are not perfectly replicated each time. This requires stringent process control to ensure absolute consistency across a large production run.

When to Choose a Batch Furnace

Your operational goals will determine if a batch furnace is the right tool for the job.

- If your primary focus is process versatility and customization: A batch furnace is the ideal choice for handling a wide mix of part geometries, materials, and heat treatment specifications.

- If your primary focus is high-precision results on smaller volumes: The superior temperature control and uniformity of a batch furnace ensure consistent quality for specialized or low-to-medium production runs.

- If your primary focus is high-volume, standardized production: You should evaluate a continuous furnace, as its automated, non-stop processing is typically more efficient for that specific goal.

Ultimately, selecting a batch furnace is a strategic decision to prioritize adaptability and precision for each specific load you process.

Summary Table:

| Aspect | Batch Furnace Characteristic |

|---|---|

| Processing Method | Treats one discrete load (batch) at a time through a complete thermal cycle. |

| Key Advantage | Exceptional flexibility; each batch can have a unique thermal recipe. |

| Ideal For | Low-to-medium volume production, varied part mixes, and high-precision requirements. |

| Considerations | Lower throughput for mass production vs. continuous furnaces; requires manual loading/unloading. |

Need a heat treatment solution that adapts to your unique production needs?

At KINTEK, we understand that precision and flexibility are paramount for specialized batches. Leveraging our exceptional R&D and in-house manufacturing, we provide diverse laboratories and workshops with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, and Atmosphere Furnaces, is complemented by strong deep customization capabilities to precisely meet your unique experimental and production requirements.

Contact our experts today to discuss how a custom batch furnace can enhance your process flexibility and ensure superior results for every load.

Visual Guide

Related Products

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What are the key features of a quartz tube furnace? Discover High-Temp Precision for Your Lab

- What is the necessity of using vacuum-sealed quartz tubes? Ensuring Integrity in Ti-Cu Alloy Heat Treatment

- What technical requirements affect the external thermal strength of furnace tubes? Optimize for High-Temp Performance

- What is the difference between an alumina tube furnace and a quartz tube furnace? Choose the Right Tube Furnace for Your Lab

- What factors should be considered when purchasing a quartz tube furnace? Ensure Reliable High-Temperature Processing