The fundamental difference between an alumina tube furnace and a quartz tube furnace lies in the material of the work tube, which dictates their maximum operating temperature, chemical resistance, and whether you can visually observe the sample during processing. Alumina tubes are opaque ceramic capable of reaching very high temperatures, while quartz tubes are transparent glass ideal for lower-temperature applications where direct observation is critical.

The decision is not about which material is "better," but which is correct for your specific thermal and observational needs. Alumina prioritizes high-temperature stability above all else, while quartz prioritizes direct visual access at more moderate temperatures.

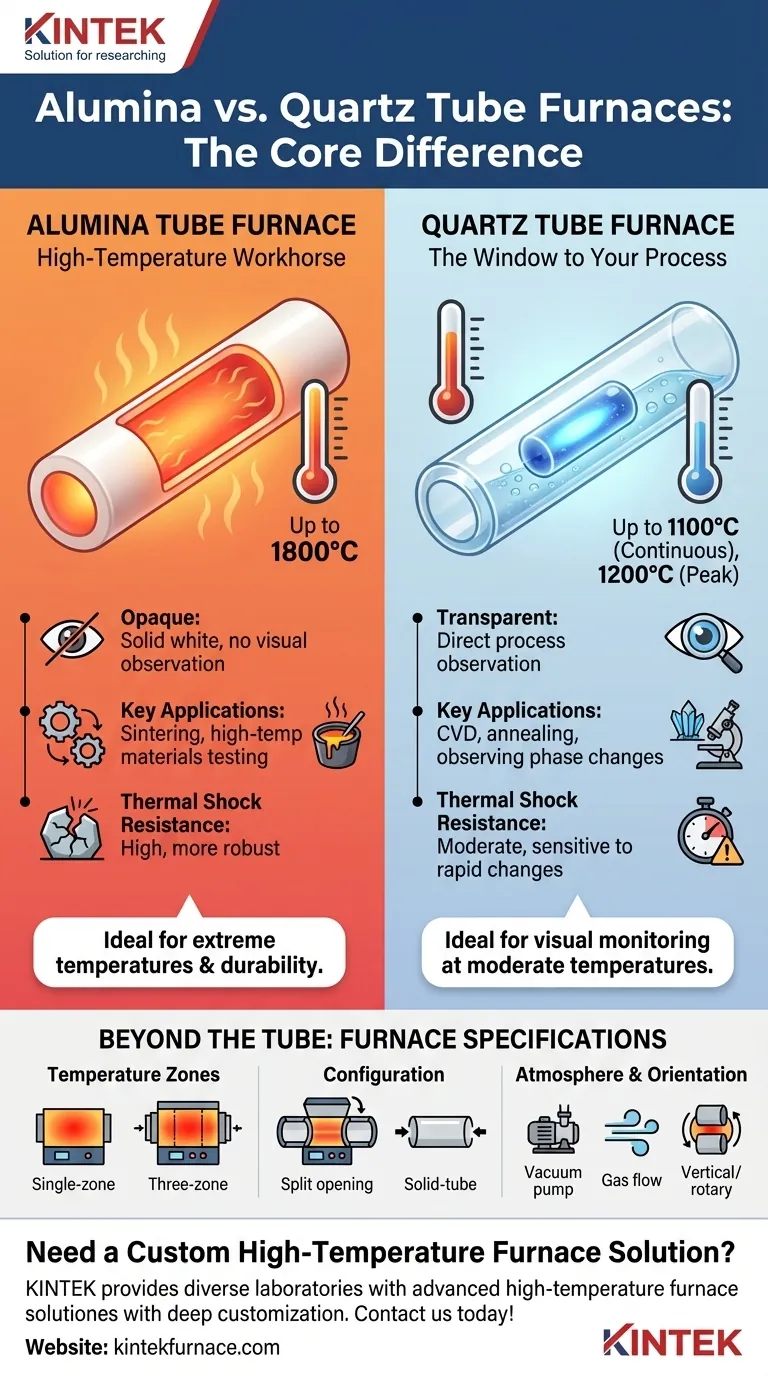

The Core Decision: Alumina vs. Quartz

At the heart of any tube furnace is the cylindrical chamber where the heating occurs. The material of this tube is the single most important factor defining the furnace's capabilities.

Alumina Tubes: The High-Temperature Workhorse

Alumina tubes are made from a high-purity ceramic, aluminum oxide (Al₂O₃). They are completely opaque, appearing as a solid white material.

Their primary advantage is an extremely high maximum operating temperature. Depending on the purity, alumina tubes can be used in furnaces that reach 1600°C or even 1800°C.

This makes them essential for processes like sintering advanced ceramics, growing certain crystals, and high-temperature materials testing. They are also highly resistant to chemical corrosion.

Quartz Tubes: The Window to Your Process

Quartz tubes are made from high-purity fused silica glass. Their defining characteristic is optical transparency.

This allows you to directly observe the material inside the furnace during a thermal cycle, which is invaluable for processes like chemical vapor deposition (CVD), observing phase changes, or annealing semiconductor wafers.

The trade-off for this transparency is a lower maximum temperature. Quartz tubes typically have a continuous use limit around 1100°C and a short-term peak of 1200°C. Above this, the material will soften (devitrify) and can fail.

Understanding the Critical Trade-offs

Choosing between these materials involves a clear set of engineering trade-offs. Misunderstanding them can lead to failed experiments or damaged equipment.

Temperature vs. Observation

This is the most straightforward trade-off. If your process requires temperatures significantly above 1200°C, alumina is your only viable choice.

If you absolutely must see your sample during the process, and the temperature remains below 1100°C, quartz is the default and correct choice.

Thermal Shock and Durability

Alumina is generally more robust and can better withstand rapid temperature changes (thermal shock). Its tough ceramic nature makes it physically durable.

Quartz is more sensitive to thermal shock. Heating or cooling the tube too quickly can cause it to crack. This requires more careful programming of heating and cooling rates.

Cost and Purity

High-purity alumina and quartz can both be expensive, but the cost is often dictated more by the tube's dimensions and purity grade than the base material itself. Always verify that the tube's purity is sufficient to prevent contamination of your sample.

Beyond the Tube: Key Furnace Specifications

The tube material is just one piece of the puzzle. To select the right furnace, you must also consider its overall design and features.

Temperature Zones and Uniformity

A single-zone furnace has one set of heating elements, creating a hot zone in the center that tapers off toward the ends.

A three-zone furnace has independent center and end-cap heaters. This design provides vastly superior temperature uniformity along the entire heated length, which is critical for processing larger samples or when precision is paramount.

Furnace Configuration: Split vs. Solid Tube

A solid tube furnace is a continuous cylinder that you load by inserting the sample from one end.

A split tube furnace is hinged, allowing the entire furnace to open like a clamshell. This provides much easier access to the work tube for placing samples or integrating complex experimental setups.

Orientation and Atmosphere Control

Furnaces can be oriented horizontally, vertically, or designed to rotate. Rotary furnaces are used for mixing powders or coatings as they are heated.

Furthermore, a critical feature is atmosphere control. Most tube furnaces can be sealed and connected to vacuum pumps and gas lines, allowing for processing in a vacuum or under a specific, controlled gas atmosphere.

Making the Right Choice for Your Application

Selecting the right furnace requires a clear understanding of your process goals.

- If your primary focus is reaching temperatures above 1200°C (e.g., sintering ceramics, melting metals): Alumina is the necessary choice due to its superior thermal stability.

- If your primary focus is visually monitoring a process (e.g., chemical vapor deposition, observing material changes): Quartz is the ideal choice, provided your process stays below its temperature limit.

- If your primary focus is achieving perfect temperature uniformity over a large sample: A three-zone furnace, regardless of tube material, will provide the most precise results.

- If your primary focus is easy sample loading or using complex apparatus: A split-tube furnace offers significantly better accessibility than a solid-tube design.

Choosing the right furnace begins with the tube material but is completed by matching the furnace's overall design to your specific process requirements.

Summary Table:

| Feature | Alumina Tube Furnace | Quartz Tube Furnace |

|---|---|---|

| Max Operating Temperature | Up to 1800°C | Up to 1100°C (continuous) |

| Transparency | Opaque | Transparent |

| Key Applications | Sintering ceramics, high-temperature testing | CVD, annealing, visual observation |

| Thermal Shock Resistance | High | Moderate |

Need a Custom High-Temperature Furnace Solution? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet your unique experimental requirements. Contact us today to discuss how we can enhance your lab's efficiency and performance!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents