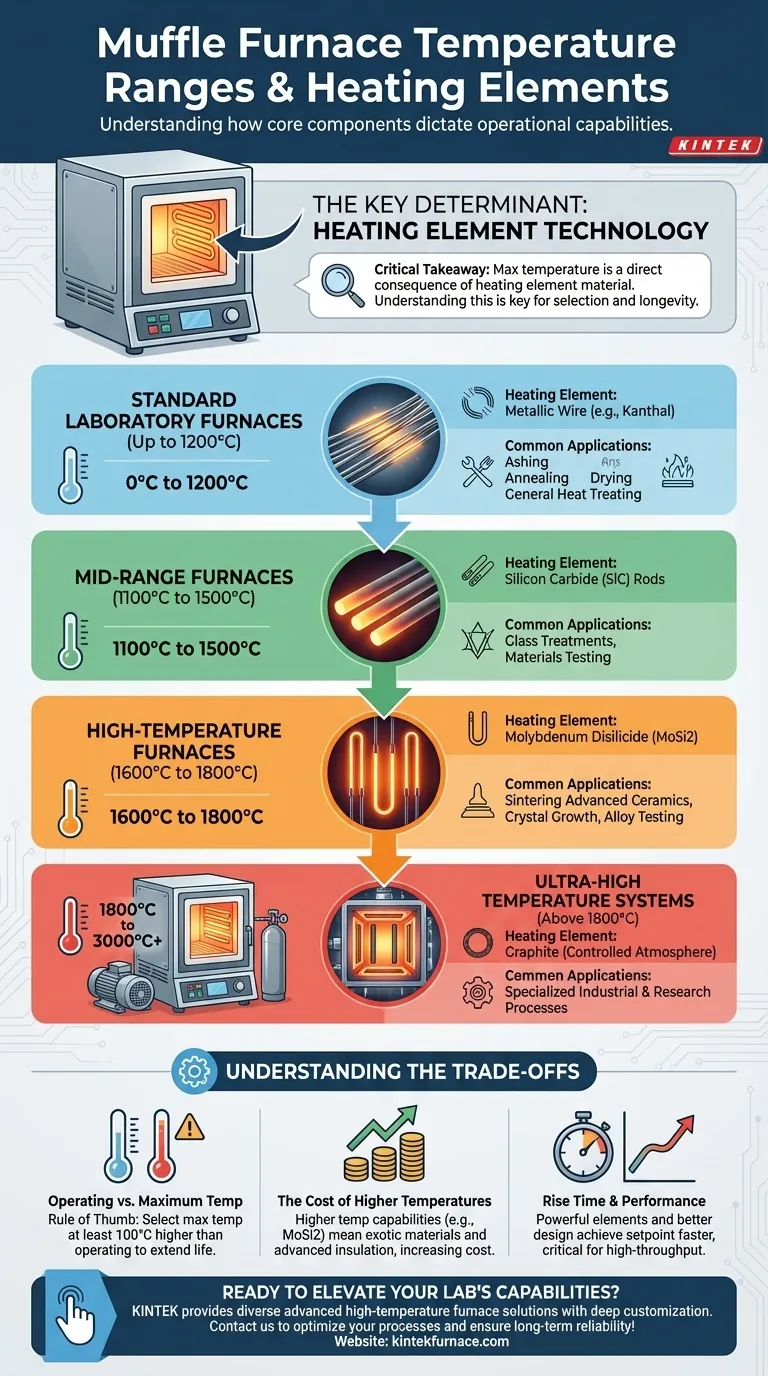

At a fundamental level, muffle furnace temperature ranges are dictated by their internal heating element technology. Standard laboratory models typically operate up to 1200°C, while high-temperature versions can reach 1800°C. Specialized industrial and research furnaces can even exceed 3000°C, though these are less common.

The critical takeaway is that a furnace's maximum temperature is not just a number, but a direct consequence of its core components. Understanding the type of heating element used is the key to selecting the right furnace for your specific temperature requirements and ensuring the longevity of your equipment.

How Temperature Capability is Determined

A muffle furnace works by heating an insulated outer chamber, which then radiates uniform heat into an inner chamber (the muffle). This indirect heating process prevents direct contact between the heating elements and the workload, ensuring a clean and homogenous temperature environment.

The Role of the Heating Element

The material used for the heating elements is the single most important factor determining a furnace's maximum operating temperature. Each material has a physical limit beyond which it will rapidly degrade or fail, primarily due to oxidation.

The Muffle Chamber Itself

The internal chamber is built from advanced, heat-resistant ceramic materials. While it must withstand the target temperatures, it is the heating elements surrounding it that generate the heat and define the operational ceiling.

Temperature Ranges by Furnace Type

Furnaces are best classified by the heating element technology they employ. This provides a clear guide to their operational capabilities and intended applications.

Standard Laboratory Furnaces (Up to 1200°C)

These furnaces almost always use metallic wire heating elements, typically an iron-chromium-aluminum alloy (like Kanthal). This technology is reliable, cost-effective, and ideal for a wide range of common laboratory tasks.

Applications include ashing, annealing, drying, and general heat treating of metals. Many common brand names, such as Thermolyne, offer models in this range.

Mid-Range Furnaces (1100°C to 1500°C)

To achieve temperatures beyond the limits of metallic wire, furnaces use silicon carbide (SiC) rod heating elements. These are more robust at higher temperatures but also more brittle and expensive.

These models bridge the gap for processes that require more heat than a standard furnace can provide, such as certain glass treatments or materials testing.

High-Temperature Furnaces (1600°C to 1800°C)

The highest tier of common laboratory furnaces relies on molybdenum disilicide (MoSi2) heating elements. These elements can operate consistently at very high temperatures, making them essential for advanced applications.

Their primary use is in scientific research and specialized manufacturing, including sintering advanced ceramics, growing crystals, and testing high-performance alloys.

Ultra-High Temperature Systems (Above 1800°C)

Furnaces exceeding 1800°C are highly specialized. They often use graphite elements and require a controlled, oxygen-free atmosphere (vacuum or inert gas) to prevent the elements from combusting. Some brands, like Carbolite, offer models that can reach up to 3000°C for niche industrial and research purposes.

Understanding the Trade-offs

Selecting a furnace involves more than just finding one that can hit your target temperature. Practical and financial considerations are crucial for making an informed decision.

Operating Temperature vs. Maximum Temperature

A furnace should not be run continuously at its maximum rated temperature. Doing so drastically shortens the life of the heating elements. As a rule, select a furnace with a maximum temperature at least 100°C higher than your normal operating temperature.

The Cost of Higher Temperatures

There is a significant cost increase associated with higher temperature capabilities. This is due not only to the more exotic heating element materials (MoSi2 is far more expensive than Kanthal wire) but also to the more advanced insulation required to safely contain the heat.

Rise Time and Performance

Rise time, or the time it takes for the furnace to reach its setpoint, is a key performance metric. Furnaces with more powerful elements and better design will heat up faster, which can be critical for high-throughput environments.

Making the Right Choice for Your Application

Use your required temperature range as the primary filter to narrow down your options and ensure you invest in the right technology for your needs.

- If your primary focus is general lab work like ashing, drying, or basic metal treatment: A standard furnace with metallic elements (up to 1200°C) is the most practical and cost-effective choice.

- If your primary focus is materials testing or processes requiring moderate heat: A mid-range furnace with silicon carbide (SiC) elements (up to 1500°C) provides necessary capability and flexibility.

- If your primary focus is advanced ceramics, sintering, or high-temperature alloy research: You must invest in a high-temperature furnace with molybdenum disilicide (MoSi2) elements (1600°C-1800°C).

Choosing the correct furnace is about precisely matching the heating technology to your application, which guarantees both operational success and long-term equipment reliability.

Summary Table:

| Furnace Type | Heating Element | Temperature Range | Common Applications |

|---|---|---|---|

| Standard Laboratory | Metallic Wire (e.g., Kanthal) | Up to 1200°C | Ashing, annealing, drying, basic heat treating |

| Mid-Range | Silicon Carbide (SiC) Rods | 1100°C to 1500°C | Glass treatments, materials testing |

| High-Temperature | Molybdenum Disilicide (MoSi2) | 1600°C to 1800°C | Sintering ceramics, crystal growth, alloy testing |

| Ultra-High Temperature | Graphite (with controlled atmosphere) | Above 1800°C up to 3000°C | Specialized industrial and research processes |

Ready to elevate your lab's capabilities? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how our furnaces can optimize your processes and ensure long-term reliability!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating