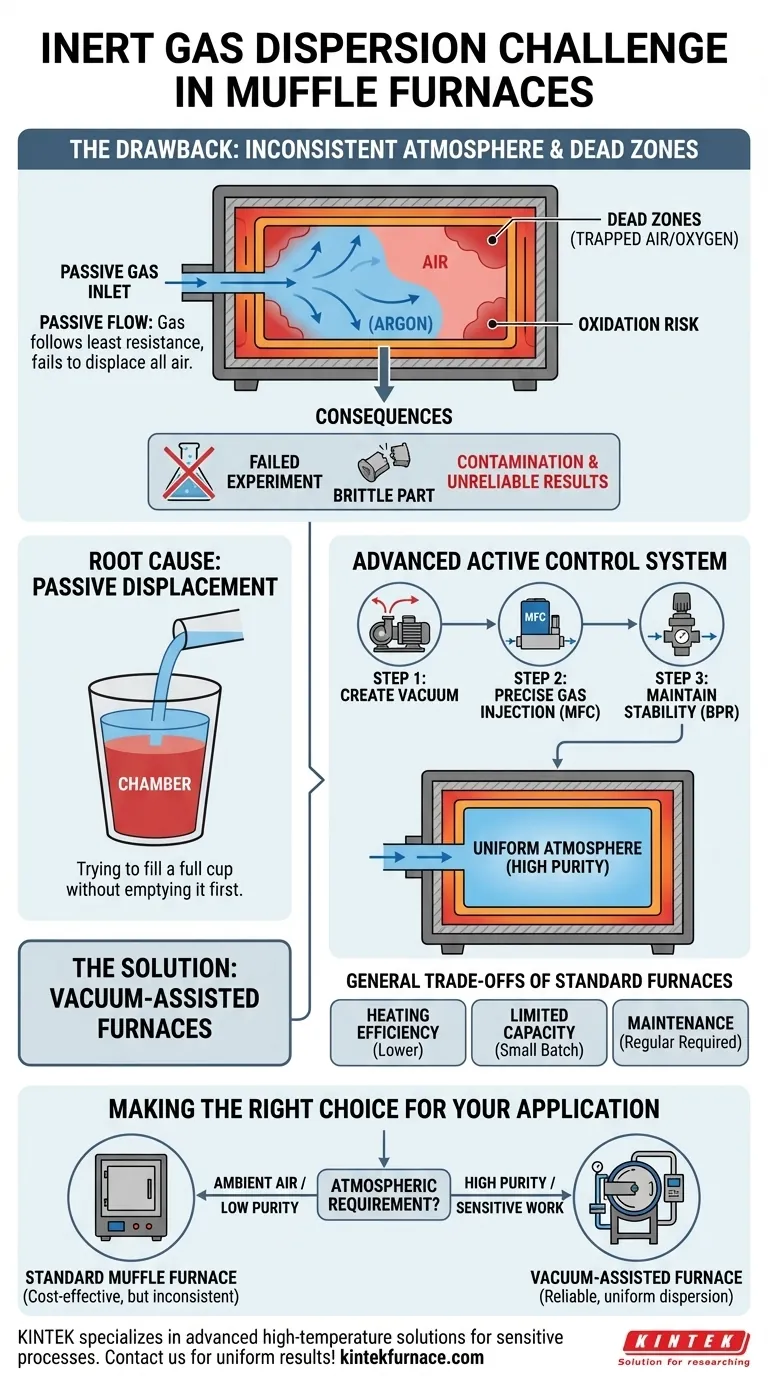

The primary drawback of a standard muffle furnace is its inability to guarantee uniform inert gas dispersion. Instead of evenly saturating the chamber, the inert gas often gets trapped in pockets, particularly near the edges and corners. This creates an inconsistent atmosphere that can compromise processes requiring a pure, oxygen-free environment.

A standard muffle furnace struggles with inert atmospheres because it relies on passive gas displacement, which is often incomplete. For applications demanding true atmospheric purity and uniformity, a system with active vacuum and pressure controls is required.

The Root Cause: Passive Flow vs. Active Control

The core issue stems from how a basic muffle furnace introduces inert gas. It simply pushes gas into the chamber, hoping it displaces the existing air. This method is fundamentally unreliable for sensitive work.

The Problem of "Dead Zones"

In a standard furnace, incoming inert gas follows the path of least resistance. It doesn't actively mix with the existing atmosphere, leading to areas where the original air is never fully purged. These "dead zones" or pockets typically form in corners and stagnant areas.

This process is like trying to fill a cup with water that's already full of a denser liquid, without first emptying it. The water will flow in, but it won't perfectly displace the original contents.

The Consequences of Inconsistent Atmosphere

For processes like annealing, brazing, or sintering sensitive materials, the presence of oxygen or moisture is a critical failure point. An inconsistent atmosphere leads directly to oxidation and contamination, resulting in failed experiments, brittle parts, and unreliable outcomes.

A process that requires 99.99% argon is not successful if pockets of 20% oxygen remain in the corners of the chamber.

The Solution: Vacuum-Assisted Furnaces

To solve the dispersion problem, advanced furnaces use a completely different methodology. They don't just push gas in; they actively manage the entire atmospheric environment.

Step 1: Creating a Vacuum

The first and most critical step is using a vacuum pump to remove the existing atmosphere from the chamber. By pulling a vacuum, the system evacuates the air from every corner, eliminating the risk of residual pockets.

Step 2: Precise Gas Injection with an MFC

Once the chamber is evacuated, a Mass Flow Controller (MFC) is used to backfill it with the desired inert gas. An MFC is a sophisticated valve that injects gas with extreme precision, often measured in milliliters per minute, ensuring the exact volume and flow rate are achieved.

Step 3: Maintaining Stability with a BPR

Throughout the heating process, a Back-Pressure Regulator (BPR) works in concert with the vacuum pump. This system maintains a steady, consistent pressure inside the chamber, preventing any outside air from leaking in and ensuring the inert gas remains evenly distributed.

Understanding the General Trade-offs

While poor gas dispersion is a key drawback for specific applications, it's important to understand the other limitations of muffle furnaces.

Heating Efficiency

Many muffle furnace designs have indirect heating elements, which can lead to lower thermal efficiency and higher energy consumption compared to other furnace types.

Limited Capacity

Standard muffle furnaces are typically designed for laboratory or small-batch production. Their capacity is often insufficient for large-scale industrial manufacturing.

Maintenance Requirements

To ensure accurate temperatures and reliable performance, muffle furnaces require regular maintenance, including calibration and potential replacement of heating elements and thermocouple sensors.

Making the Right Choice for Your Application

Choosing a furnace depends entirely on the atmospheric requirements of your process.

- If your primary focus is general heat treatment in ambient air: A standard muffle furnace is a cost-effective and perfectly suitable tool.

- If your primary focus is a low-purity, non-critical process: A standard furnace with a continuous gas purge may be sufficient, but you must accept the high risk of an inconsistent atmosphere.

- If your primary focus is a high-purity, uniform inert atmosphere for sensitive work: A vacuum muffle furnace with an MFC and BPR is the only reliable solution.

Ultimately, understanding your process's sensitivity to atmospheric contamination is the key to selecting the right equipment.

Summary Table:

| Aspect | Standard Muffle Furnace | Advanced Vacuum-Assisted Furnace |

|---|---|---|

| Gas Dispersion | Poor, with dead zones and inconsistent atmosphere | Excellent, with uniform dispersion via vacuum and MFC |

| Atmosphere Control | Passive gas displacement, unreliable for purity | Active control with vacuum, MFC, and BPR for high purity |

| Suitability | Best for ambient air or low-purity processes | Ideal for high-purity, sensitive applications like annealing |

| Key Features | Cost-effective, simple design | Precise gas injection, stable pressure, reduced contamination |

Struggling with inconsistent atmospheres in your lab? KINTEK specializes in advanced high-temperature furnace solutions tailored for sensitive processes. Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems with deep customization to meet your unique experimental needs. Ensure uniform inert gas dispersion and reliable results—contact us today to discuss how our furnaces can enhance your workflow!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the key features of an atmosphere box furnace? Unlock Precise Heat Processing in Controlled Environments

- What are the development prospects of atmosphere box furnaces in the aerospace industry? Unlock Advanced Material Processing for Aerospace Innovation

- What are the primary inert gases used in vacuum furnaces? Optimize Your Heat Treatment Process

- What is an atmosphere protection muffle furnace? Unlock Precise Heat Treatment in Controlled Environments

- What is inert gas technology used for in high-temperature atmosphere vacuum furnaces? Protect Materials and Speed Up Cooling