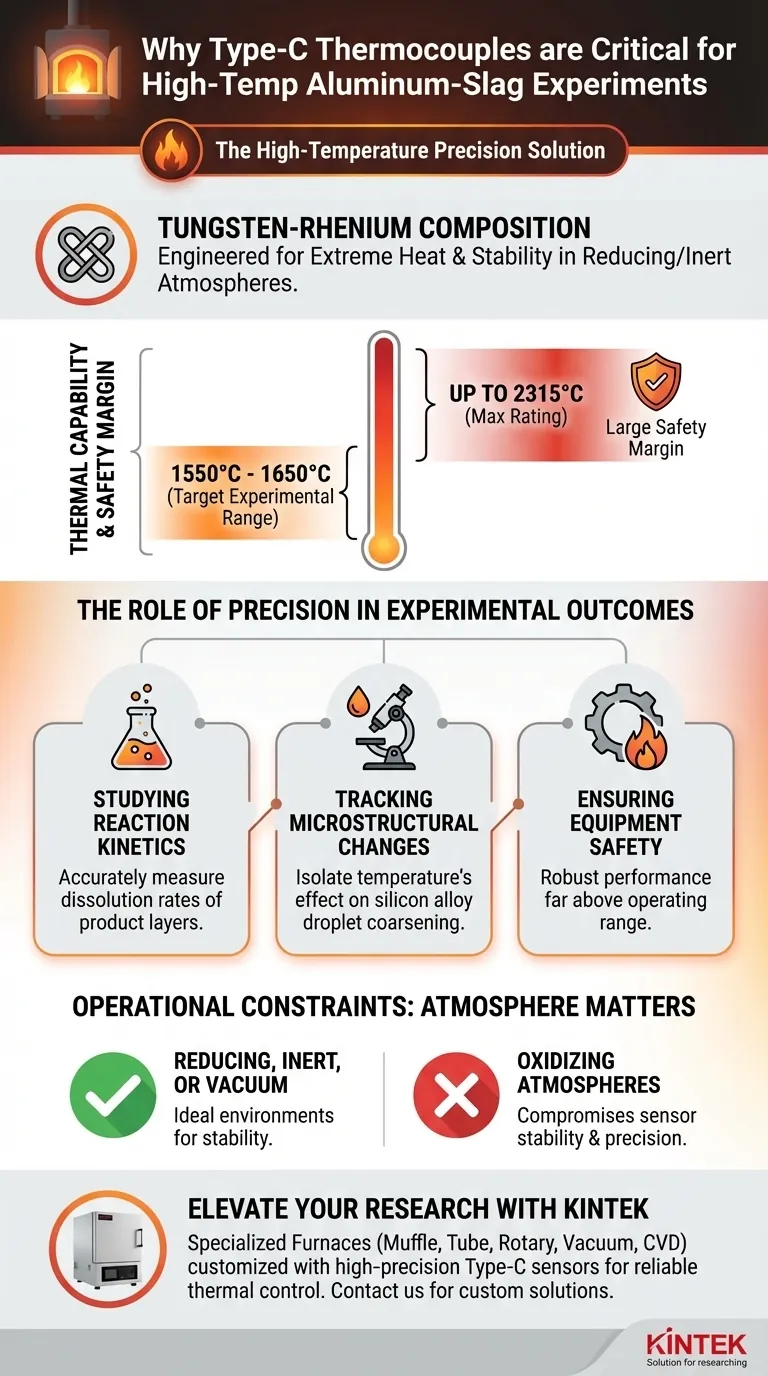

The Type-C thermocouple is the critical instrument of choice for high-temperature aluminum-slag experiments because of its robust Tungsten-Rhenium composition. This specific alloy allows it to deliver high precision and stability in reducing or inert atmospheres, easily withstanding the experimental operating range of 1550°C to 1650°C while offering a safety margin up to 2315°C.

The selection of Type-C sensors is not merely about surviving the heat; it is about ensuring the precise temperature control necessary to accurately measure sensitive reaction kinetics and metallurgical transformations.

Thermal Capability and Material Stability

Engineering for Extreme Heat

The Type-C thermocouple is constructed using Tungsten-Rhenium alloys. This material composition is specifically engineered to function in environments where standard sensors would fail.

While the aluminum-slag experiments are conducted between 1550°C and 1650°C, the Type-C is rated for temperatures up to 2315°C. This significant thermal headroom ensures the sensor remains stable and accurate, never operating near its failure point during the test.

Environmental Compatibility

High-temperature reactions often require specific atmospheric controls to prevent unwanted oxidation. The Type-C thermocouple is explicitly selected for its ability to perform in reducing or inert atmospheres.

This compatibility ensures that the sensor provides consistent readings without degrading due to the chemical environment of the furnace.

The Role of Precision in Experimental Outcomes

Controlling Reaction Variables

In aluminum-slag setups, temperature is not just a condition; it is a decisive variable. The high precision of the Type-C thermocouple allows researchers to maintain exact control over the thermal environment.

Measuring Kinetic Phenomena

Precise temperature data is required to study the dissolution rate of product layers. Small fluctuations in heat could skew these measurements, leading to incorrect conclusions about reaction speeds.

Tracking Microstructural Changes

The stability of the Type-C sensor is also critical for observing the coarsening of silicon alloy droplets. Accurate thermal monitoring allows researchers to isolate temperature as a factor in how these droplets evolve and interact within the slag.

Operational Constraints

Atmospheric Limitations

While the Type-C thermocouple is superior in specific environments, it is important to note its operational constraints regarding atmosphere. The primary reference highlights its effectiveness in reducing or inert atmospheres.

Using this sensor outside of these specific environmental conditions could compromise its stability or precision. It is a specialized tool designed for controlled metallurgical environments, rather than a universal solution for all high-temperature applications.

Making the Right Choice for Your Goal

To ensure the success of your high-temperature experiments, consider how the specific capabilities of the Type-C thermocouple align with your objectives.

- If your primary focus is Studying Reaction Kinetics: Rely on the Type-C to maintain the stable temperatures needed to accurately measure the dissolution rates of product layers.

- If your primary focus is Microstructural Analysis: Use the high precision of this sensor to correlate exact temperature levels with the coarsening behavior of silicon alloy droplets.

- If your primary focus is Equipment Safety: Leverage the 2315°C upper limit to provide a robust safety margin above the standard 1650°C operating range.

Selecting the right sensor is the first step in converting high-temperature chaos into actionable scientific data.

Summary Table:

| Feature | Type-C Thermocouple Specification |

|---|---|

| Material Composition | Tungsten-Rhenium Alloy |

| Max Operating Temperature | Up to 2315°C (4199°F) |

| Target Experimental Range | 1550°C to 1650°C |

| Ideal Atmospheres | Reducing, Inert, or Vacuum |

| Primary Applications | Reaction kinetics, metallurgical transformations, silicon alloy study |

Elevate Your High-Temperature Research with KINTEK

Precision in metallurgy begins with reliable thermal control. Whether you are studying reaction kinetics or microstructural changes in aluminum-slag, KINTEK provides the specialized equipment necessary for accuracy. Backed by expert R&D and world-class manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all of which can be customized with high-precision Type-C sensors to meet your unique experimental needs.

Ready to optimize your lab's thermal performance? Contact our engineering team today to discuss your custom furnace requirements and ensure your next experiment is backed by KINTEK excellence.

Visual Guide

References

- Harald Philipson, Kristian Etienne Einarsrud. Investigation of Liquid–Liquid Reaction Phenomena of Aluminum in Calcium Silicate Slag. DOI: 10.3390/ma17071466

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What are the key characteristics of molybdenum disilicide (MoSi2) heating elements? Unlock High-Temp Performance

- How do SIC heating elements compare to traditional resistance heating elements in terms of performance? Superior High-Temp Performance

- How do ceramic heating elements compare to metal ones? Discover the Superior Choice for Your Heating Needs

- How does the thermal stability of quartz tubes benefit high-temperature applications? Ensure Reliable Performance in Extreme Heat

- Which industries commonly use high-temperature heating elements? Essential for Metallurgy, Chemicals, and Electronics

- What protective mechanism allows MoSi2 heating elements to be used in oxidizing atmospheres? Self-Healing Silica Layer Explained

- What are the characteristics of molybdenum disilicide heating elements? Unlock High-Temp Performance

- What is the temperature range for MoSi2 heating elements? Maximize Lifespan in High-Temp Applications