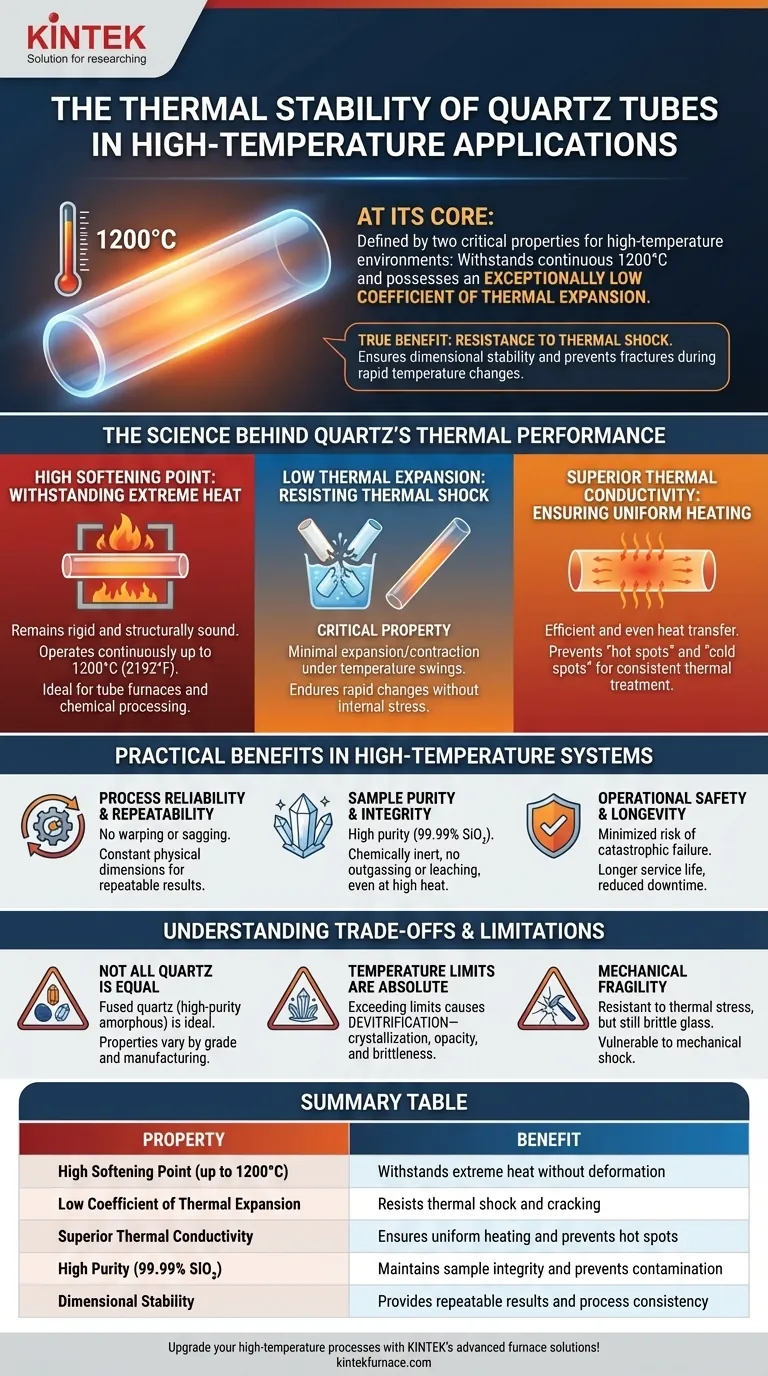

At its core, the thermal stability of a quartz tube is defined by two critical properties that allow it to excel in high-temperature environments. It can withstand continuous operating temperatures up to 1200°C, and its exceptionally low coefficient of thermal expansion prevents it from deforming or cracking even during rapid temperature changes. This combination ensures operational reliability and process consistency.

The true benefit of quartz's thermal stability is not just its ability to endure high heat, but its capacity to resist thermal shock. This ensures that equipment remains dimensionally stable and free from fractures, protecting the integrity of both the process and the materials being treated.

The Science Behind Quartz's Thermal Performance

To understand why quartz is a cornerstone material in high-temperature applications, we must look at the specific physical properties that contribute to its stability. These characteristics work together to create a reliable and predictable environment.

High Softening Point: Withstanding Extreme Heat

Quartz glass has a very high softening point, allowing it to remain rigid and structurally sound at temperatures where many other materials would fail. Different grades of quartz can operate continuously at temperatures around 1200°C (2192°F).

This makes it an ideal material for containment in tube furnaces, chemical processing, and other thermal treatments that require a stable, inert vessel in extreme heat.

Low Thermal Expansion: Resisting Thermal Shock

This is arguably the most critical property. The coefficient of thermal expansion (CTE) measures how much a material expands or contracts when its temperature changes. Quartz has an extremely low CTE.

Imagine plunging a hot ceramic dish into cold water; the rapid contraction causes stress that shatters it. Because quartz barely expands or contracts, it can endure these rapid temperature swings without building up internal stress, making it highly resistant to thermal shock.

Superior Thermal Conductivity: Ensuring Uniform Heating

Quartz allows heat to transfer through its walls efficiently and evenly. This property is vital for applications where temperature uniformity across a sample is critical.

By preventing "hot spots" and "cold spots," a quartz tube ensures that the entire sample inside receives a consistent and predictable thermal treatment, which is essential for scientific experiments and semiconductor manufacturing.

Practical Benefits in High-Temperature Systems

The scientific properties of quartz translate directly into tangible advantages in real-world industrial and laboratory settings.

Process Reliability and Repeatability

Because a quartz tube does not warp, sag, or deform under heat, the physical dimensions of the processing environment remain constant. This dimensional stability is crucial for achieving repeatable results run after run, whether in materials research or large-scale production.

Sample Purity and Integrity

High-purity quartz (often 99.99% SiO₂) is chemically inert and does not outgas or leach impurities into the sample, even at high temperatures. This is non-negotiable in fields like semiconductor manufacturing and materials science, where even trace contamination can ruin a product or experiment.

Operational Safety and Longevity

A tube that resists cracking from thermal shock is a safer tube. It minimizes the risk of catastrophic failure that could expose operators to extreme heat or release reactive chemicals. This durability also leads to a longer service life, reducing downtime and maintenance costs.

Understanding the Trade-offs and Limitations

While exceptional, quartz is not without its limitations. Understanding these trade-offs is key to using it effectively and safely.

Not All Quartz Is Created Equal

The term "quartz" can refer to different materials, with fused quartz being the high-purity, amorphous version ideal for these applications. The maximum temperature, purity, and optical properties can vary based on the manufacturing process and grade.

Temperature Limits Are Absolute

While its thermal stability is excellent, it is not infinite. Operating a quartz tube above its specified working temperature for extended periods can lead to devitrification—a process where the amorphous glass structure begins to crystallize. This makes it opaque, brittle, and prone to failure.

Mechanical Fragility

Quartz is highly resistant to thermal stress, but it is still a glass. It is brittle and can be easily fractured by mechanical shock, such as being dropped or struck by a hard object. Careful handling is always required.

Making the Right Choice for Your Application

Selecting the right material requires aligning its properties with your primary objective. Quartz stands out for its unique combination of thermal, chemical, and optical characteristics.

- If your primary focus is sample purity and process repeatability: The high purity and dimensional stability of a quartz tube make it the ideal choice for semiconductor processing and scientific research.

- If your primary focus is operational safety and resistance to thermal shock: Quartz's extremely low thermal expansion provides unmatched reliability during the rapid heating and cooling cycles common in tube furnaces.

- If your primary focus is visual monitoring of a high-temperature process: The optical clarity of quartz, combined with its thermal resilience, makes it uniquely suitable for applications like sight glasses and reactor vessels.

Ultimately, leveraging the thermal properties of quartz transforms high-temperature challenges into predictable and reliable processes.

Summary Table:

| Property | Benefit |

|---|---|

| High Softening Point (up to 1200°C) | Withstands extreme heat without deformation |

| Low Coefficient of Thermal Expansion | Resists thermal shock and cracking |

| Superior Thermal Conductivity | Ensures uniform heating and prevents hot spots |

| High Purity (99.99% SiO₂) | Maintains sample integrity and prevents contamination |

| Dimensional Stability | Provides repeatable results and process consistency |

Upgrade your high-temperature processes with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we offer a diverse product line including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, enhancing reliability, purity, and efficiency. Contact us today to discuss how we can support your laboratory's success!

Visual Guide

Related Products

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What materials are used for the tubes in a High Temperature Tube Furnace? Choose the Right Tube for Your Lab

- Why is a high-precision vacuum tube furnace essential for CVD graphene? Master Growth Control & Purity

- How to clean a tube furnace? A Step-by-Step Guide to Safe and Effective Maintenance

- What role do tube furnaces play in semiconductor and battery production? Unlock Precision in High-Temp Processing

- What industrial and research applications are tube furnaces used for? Unlock Precise Thermal Processing Solutions