At their core, Molybdenum Disilicide (MoSi2) heating elements are designed for the most demanding high-temperature environments. While their absolute maximum surface temperature can reach up to 1900°C (3452°F), their practical and recommended maximum furnace operating temperature is typically between 1600°C and 1800°C. This distinction is critical for proper furnace design and operation.

The single most important takeaway is that MoSi2 elements are not defined by one temperature, but by two: the element's peak surface temperature and the furnace's practical operating temperature. Understanding this difference is the key to leveraging their primary advantage, which is exceptional service life in processes running consistently above 1500°C.

The Two Critical Temperature Ratings

To select and use MoSi2 elements correctly, you must distinguish between the temperature the element itself can survive and the temperature it can sustain within a furnace chamber.

Maximum Element Temperature (up to 1900°C)

This refers to the highest temperature the surface of the heating element can withstand in an oxidizing atmosphere. At these extreme temperatures, the molybdenum disilicide reacts with oxygen to form a protective, self-healing layer of quartz glass (SiO₂).

This passive layer prevents further oxidation and is the reason MoSi2 elements can function at temperatures far beyond most other metallic or ceramic elements. This peak rating is a measure of material survivability, not a recommended process temperature.

Maximum Furnace Operating Temperature (1600°C - 1800°C)

This is the more practical and important figure for any engineer or operator. It represents the highest sustainable air temperature inside the furnace chamber.

This rating is always lower than the element's maximum surface temperature to account for thermal gradients, safety margins, and the need for efficient heat transfer from the element to the furnace load. Most industrial processes using MoSi2 operate in the 1600°C to 1700°C range for optimal element life and process stability.

Performance Profile: When to Choose MoSi2

MoSi2 elements are a specialized solution, not a universal one. Their value becomes clear when compared to other high-temperature elements, such as Silicon Carbide (SiC).

Superior Longevity at Extreme Heat

The primary advantage of MoSi2 is its exceptional performance and lifespan in applications running above 1500°C. While SiC elements can operate up to 1600°C, MoSi2 elements exhibit significantly longer service life when operated consistently in the 1600°C to 1800°C range.

High Power Density and Fast Ramp-Up

MoSi2 elements can handle high electrical loads, allowing for a high concentration of power in a compact space. This enables furnace designs with rapid heating rates, which is critical for many modern lab and production processes.

Minimal Maintenance Requirements

Unlike some elements that age and require resistance adjustments, MoSi2 elements maintain a relatively stable resistance throughout their life. This simplifies power control and reduces the need for frequent maintenance, leading to lower operating costs and less downtime.

Understanding the Trade-offs and Risks

No material is without its drawbacks. An objective evaluation of MoSi2 requires acknowledging its operational sensitivities.

Brittleness at Low Temperatures

MoSi2 is a ceramic material and is inherently brittle at room temperature. It must be handled with care during installation and maintenance. More importantly, it can suffer from "pesting," a form of low-temperature oxidation between 400°C and 700°C that can cause the element to disintegrate. This makes them less suitable for applications with frequent, slow cycling through this temperature zone.

Susceptibility to Contamination

The protective silica layer is vulnerable to chemical attack. Contaminants from process materials, such as paints or improperly dried zirconia in dental furnaces, can degrade the element and lead to premature failure. Maintaining a clean furnace environment is non-negotiable.

Unsuitability for Certain Atmospheres

MoSi2 elements are designed to operate in air or other oxidizing atmospheres where the protective silica layer can form and regenerate. They are generally not suitable for use in reducing atmospheres, which will strip this protective layer and destroy the element.

Making the Right Choice for Your Application

Choosing the correct heating element requires looking beyond a single temperature rating and considering the entire operational context of your process.

- If your primary focus is operating consistently above 1600°C: MoSi2 is almost always the superior technical choice due to its unmatched longevity at these extreme temperatures.

- If your process operates primarily between 1400°C and 1600°C: Silicon Carbide (SiC) becomes a highly competitive alternative that may offer a better balance of cost and performance.

- If your process involves potential contaminants or frequent slow heating cycles: You must design controls and procedures to mitigate MoSi2's vulnerability to chemical attack and low-temperature pesting.

Ultimately, an informed decision rests on matching the unique performance profile of the element to the specific demands of your thermal process.

Summary Table:

| Aspect | Details |

|---|---|

| Maximum Element Temperature | Up to 1900°C (surface) |

| Maximum Furnace Operating Temperature | 1600°C - 1800°C (recommended) |

| Key Advantages | Superior longevity above 1500°C, high power density, minimal maintenance |

| Key Limitations | Brittleness at low temps, susceptibility to contamination, not for reducing atmospheres |

| Best For | Applications consistently above 1600°C with clean, oxidizing environments |

Need a reliable high-temperature furnace solution? KINTEK specializes in advanced heating elements and custom furnace designs to meet your exact needs. Leveraging exceptional R&D and in-house manufacturing, we offer products like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure optimal performance for your unique experimental requirements. Contact us today to enhance your lab's efficiency and achieve precise thermal processing!

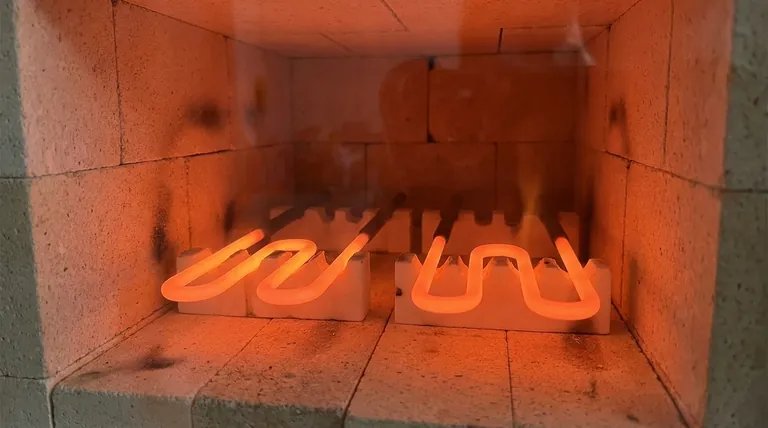

Visual Guide

Related Products

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What are the key differences between SiC and MoSi2 heating elements in sintering furnaces? Choose the Right Element for Your High-Temp Needs

- What are the advantages of using molybdenum-disilicide heating elements for aluminum alloy processing? (Rapid Heating Guide)

- What types of molybdenum disilicide heating elements are available? Choose the Right Element for Your High-Temp Needs

- What are the primary applications of Molybdenum Disilicide (MoSi2) heating elements in furnaces? Achieve High-Temp Excellence

- What are the primary applications of MoSi2 heating elements in research? Achieve Reliable High-Temp Control for Material Synthesis