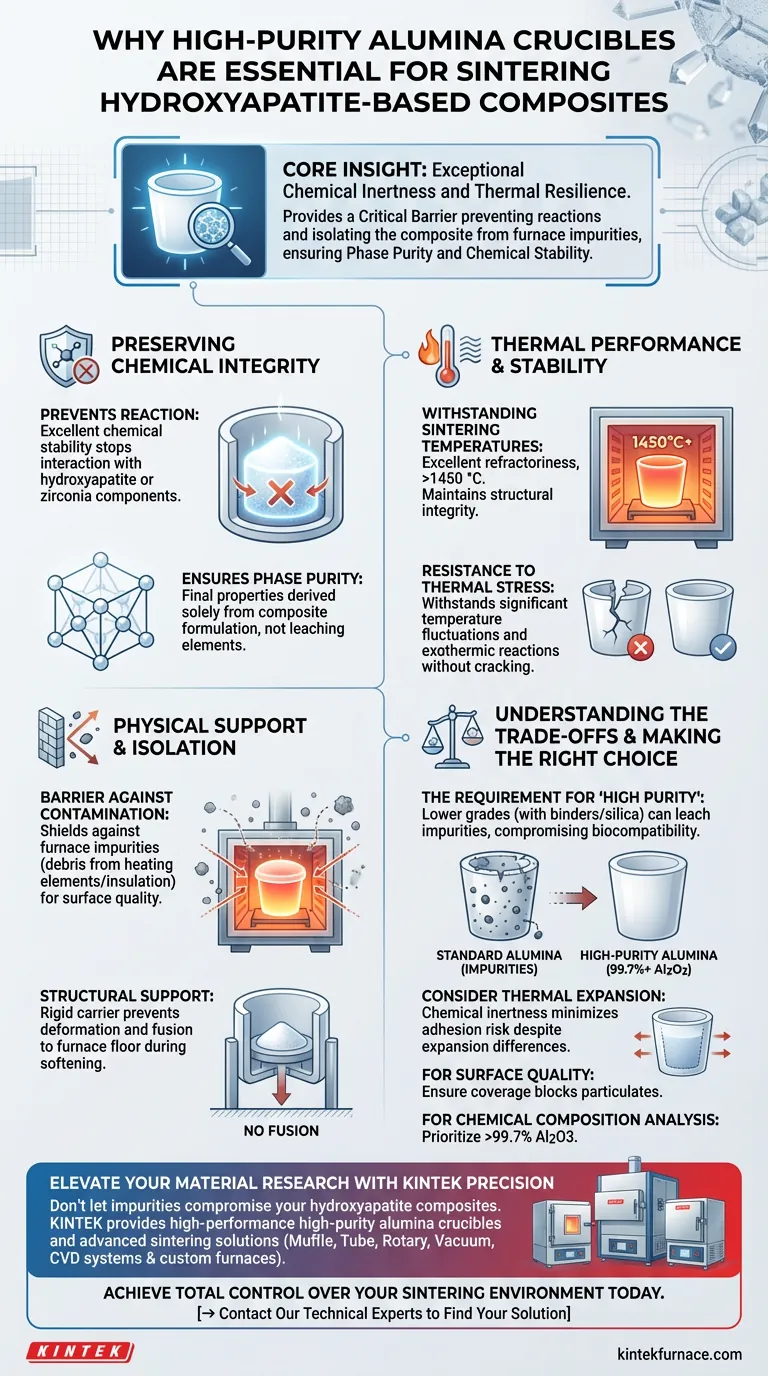

The necessity of high-purity alumina crucibles stems from their exceptional chemical inertness and thermal resilience. When sintering hydroxyapatite-based composite materials, these crucibles provide a critical barrier that prevents chemical reactions between the container and the sample. Furthermore, they physically isolate the composite from furnace impurities, ensuring the final specimen maintains its intended surface quality and chemical stability.

Core Insight: High-purity alumina is chosen not merely for its ability to withstand heat, but for its strict chemical neutrality. It guarantees that the physical support system does not alter the composite's phase purity or introduce environmental contaminants during the sintering process.

Preserving Chemical Integrity

Preventing Reaction with the Composite

The primary risk during sintering is the potential for the carrier material to react with the sample. High-purity alumina demonstrates excellent chemical stability.

This stability ensures that the crucible does not react chemically with the hydroxyapatite or zirconia components of the composite. By eliminating carrier-sample interaction, you preserve the fundamental chemical composition of your material.

Ensuring Phase Purity

Maintaining the purity of the bulk material is essential for accurate experimental results. Just as alumina preserves phase purity in materials like Ti3AlC2, it serves the same function for hydroxyapatite.

By using a chemically inert carrier, you ensure that the final properties of the sintered specimen are derived solely from the composite formulation, not from leaching elements in the crucible.

Thermal Performance and Stability

Withstanding Sintering Temperatures

Hydroxyapatite composites often require high sintering temperatures to achieve density. High-purity alumina offers excellent refractoriness, capable of withstanding temperatures exceeding 1450 °C.

This thermal resistance allows the crucible to maintain its structural integrity without softening or deforming. It acts as a stable container throughout the heating cycle, regardless of the duration.

Resistance to Thermal Stress

Sintering processes involve significant temperature fluctuations. High-purity alumina is selected for its ability to withstand thermal shock.

Whether the process involves gradual heating or more intense exothermic reactions, the material resists cracking. This prevents catastrophic failure of the container, which would otherwise ruin the sample and potentially damage the furnace.

Physical Support and Isolation

A Barrier Against Contamination

Beyond chemical reactions, the sintering environment itself can be a source of contamination. The crucible acts as a physical shield.

It prevents furnace impurities—such as debris from heating elements or insulation—from coming into contact with the composite. This is vital for ensuring the surface quality of the sintered specimens.

Structural Support

During the sintering phase, materials may undergo shrinkage or temporary softening. The alumina crucible acts as a rigid sintering carrier.

It supports the samples effectively, ensuring they retain their intended geometry while preventing them from fusing to the furnace floor.

Understanding the Trade-offs

The Requirement for "High Purity"

It is critical to distinguish between standard alumina and high-purity alumina. Using lower-grade alumina crucibles can introduce the very impurities you are trying to avoid.

If the alumina contains binders or silica impurities, these can leach into the hydroxyapatite at high temperatures, compromising the biocompatibility or mechanical properties of the composite.

Thermal Expansion Mismatch

While alumina is stable, one must consider the thermal expansion coefficient of the sample versus the crucible.

If the composite material expands significantly more than the alumina, or if it adheres to the crucible walls, mechanical stresses can occur during cooling. However, the chemical inertness of high-purity alumina generally minimizes adhesion, mitigating this risk.

Making the Right Choice for Your Goal

If your primary focus is Surface Quality:

- Ensure the crucible covers the sample sufficiently to block particulate matter from the furnace atmosphere.

If your primary focus is Chemical Composition Analysis:

- Prioritize the highest purity grade available (e.g., >99.7% Al2O3) to eliminate any risk of background interference or elemental leaching.

High-purity alumina is the industry standard for sintering hydroxyapatite because it renders the containment variable invisible, allowing the true properties of your composite to emerge.

Summary Table:

| Feature | High-Purity Alumina Benefit | Impact on Hydroxyapatite Sintering |

|---|---|---|

| Chemical Stability | Exceptional inertness (99.7%+ Al2O3) | Prevents reaction with sample & preserves phase purity |

| Thermal Resistance | Withstands temperatures >1450°C | Maintains structural integrity during high-temp densification |

| Thermal Shock | High resistance to temperature swings | Prevents crucible cracking and sample loss |

| Physical Shielding | Barrier against furnace debris | Protects surface quality from insulation/element impurities |

| Rigidity | High structural support | Prevents geometry deformation and furnace floor fusion |

Elevate Your Material Research with KINTEK Precision

Don't let impurities compromise your hydroxyapatite composites. KINTEK provides high-performance high-purity alumina crucibles and advanced sintering solutions designed for the most demanding laboratory environments.

Backed by expert R&D and world-class manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, as well as customizable lab high-temp furnaces tailored to your unique research needs.

Achieve total control over your sintering environment today.

→ Contact Our Technical Experts to Find Your Solution

Visual Guide

References

- S.V. Maksymova, V.V. Voronov. Morphology of Barrier Coatings and Formation of an Interphase Boundary by Brazing of Dissimilar Alloys. DOI: 10.15407/mfint.45.08.0963

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Magnesium Extraction and Purification Condensing Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What is the technical purpose of double-sealing raw materials in vacuum quartz tubes? Expert Synthesis Guide

- What is the function of a water-cooled jacket on a sampling probe? Optimize Atomization and Protect Hardware

- Why are high-purity ceramic boats used for V2O5 and VSe2 deposition? Ensure Film Purity and Thermal Stability

- How are quartz tubes used in laboratory applications? Essential for High-Temp, High-Purity Processes

- What is the function of an alumina boat during high-temperature activation of porous carbon? Durable Lab Solutions

- What is the technical value of using precise digital PID temperature controllers? Enhancing Ceramic Property Analysis

- What role does a rotary evaporator play in microalgae-based nanomaterials? Protect Bio-Reductive Activity for Synthesis

- Why is temperature-controlled heating equipment required for calcium perrhenate? Ensure Rhenium Stability at 140 °C