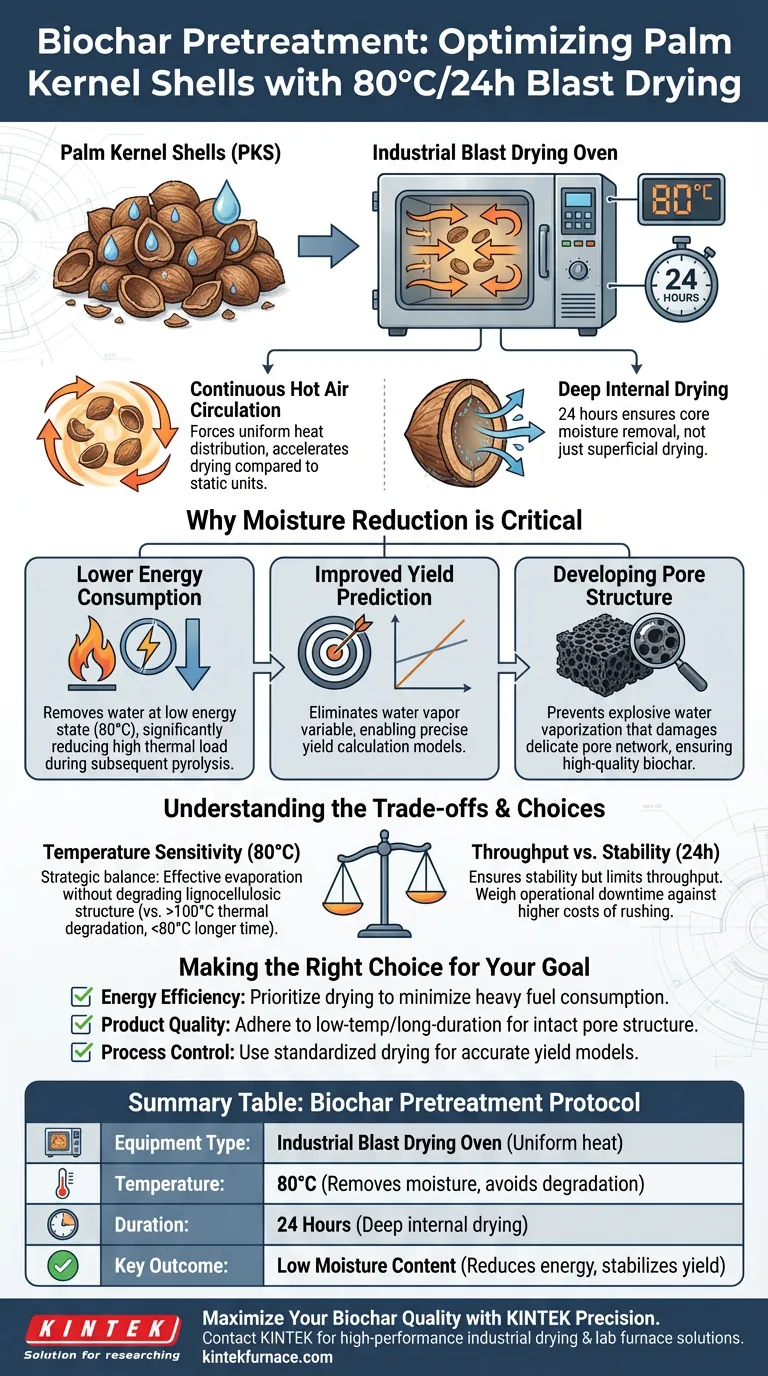

The specific use of an industrial blast drying oven at 80°C for 24 hours is a critical pretreatment step designed to minimize energy waste and stabilize the raw material. This process utilizes continuous hot air circulation to thoroughly remove moisture from palm kernel shells (PKS) without chemically altering the biomass. By achieving a low, consistent moisture level, this pretreatment optimizes the material for the subsequent, more energy-intensive pyrolysis stage.

Core Takeaway Reducing moisture content during pretreatment is essential for operational efficiency and product quality. It lowers the energy required for slow pyrolysis, prevents water vapor from skewing yield prediction models, and establishes the physical foundation necessary for developing a high-quality biochar pore structure.

The Mechanics of Moisture Removal

Continuous Hot Air Circulation

The "blast" aspect of the oven refers to active air circulation. Unlike static ovens, these units force hot air to move continuously around the palm kernel shells.

This ensures uniform heat distribution. It prevents pockets of humidity from lingering around the biomass, which significantly accelerates the drying process compared to passive heating.

Deep Internal Drying

Drying for a sustained period of 24 hours ensures the moisture removal is not just superficial.

Short drying times often leave the core of the shell wet. The 24-hour duration allows heat to penetrate the dense shell structure, driving out moisture from the inside out.

Why Moisture Reduction is Critical

Lowering Pyrolysis Energy Consumption

The primary reason for this pretreatment is energy efficiency. If you feed wet biomass into a pyrolysis reactor, a significant amount of energy is wasted simply boiling off water.

By removing this water at 80°C—a relatively low energy state—you reduce the thermal load required during slow pyrolysis, where temperatures are much higher and energy generation is more costly.

Improving Yield Prediction Accuracy

Water vapor introduces a variable that complicates the control of the production process.

Excess moisture can interfere with biochar yield prediction models. By standardizing the moisture content beforehand, you remove this noise, allowing for precise calculations regarding expected output.

Developing Pore Structure

The physical quality of biochar is defined by its porosity. The Primary Reference indicates that moisture removal is vital for the proper development of the biochar's internal pore structure.

If water remains trapped during high-temperature processing, it can vaporize explosively or unevenly, potentially damaging the delicate pore network you are trying to create.

Understanding the Trade-offs

Temperature Sensitivity

Selecting 80°C is a strategic balance. It is high enough to evaporate water effectively but low enough to avoid degrading the biomass components.

Higher temperatures (e.g., above 100°C) speed up drying but risk thermally degrading the lignocellulosic structure before pyrolysis even begins. Lower temperatures would require significantly longer than 24 hours to achieve the same dryness.

Throughput vs. Stability

The 24-hour cycle is a bottleneck in production speed. While it ensures stability, it limits throughput.

Operators must weigh the benefit of a perfectly dried feedstock against the operational downtime required to achieve it. However, rushing this step often leads to higher costs and lower quality later in the process.

Making the Right Choice for Your Goal

To determine if this specific protocol aligns with your production needs, consider your primary objectives:

- If your primary focus is Energy Efficiency: Prioritize this drying step to minimize the heavy fuel consumption required during the high-temperature pyrolysis phase.

- If your primary focus is Product Quality: Adhere strictly to the low-temperature, long-duration drying to ensure the internal pore structure of the biochar is not compromised by rapid steam expansion.

- If your primary focus is Process Control: Use this standardized drying protocol to eliminate moisture as a variable, ensuring your yield prediction models remain accurate.

Effective biochar production begins not in the reactor, but in the careful preparation of the raw material.

Summary Table:

| Parameter | Specification | Purpose in Biochar Pretreatment |

|---|---|---|

| Equipment Type | Industrial Blast Drying Oven | Ensures uniform heat via continuous hot air circulation |

| Temperature | 80°C | Removes moisture without degrading lignocellulosic structure |

| Duration | 24 Hours | Facilitates deep internal drying of dense shell cores |

| Key Outcome | Low Moisture Content | Reduces pyrolysis energy load and stabilizes yield models |

Maximize Your Biochar Quality with KINTEK Precision

Don't let moisture compromise your carbonization results. Backed by expert R&D and world-class manufacturing, KINTEK provides high-performance industrial blast drying ovens and specialized lab furnaces—including Muffle, Tube, and Vacuum systems—engineered for precise thermal pretreatment. Whether you are processing biomass or advanced materials, our customizable solutions ensure uniform heating and superior energy efficiency.

Ready to optimize your high-temperature processes? Contact KINTEK today to find the perfect drying solution for your unique production needs.

Visual Guide

References

- Hani Hussain Sait, Bamidele Victor Ayodele. Hybrid Analysis of Biochar Production from Pyrolysis of Agriculture Waste Using Statistical and Artificial Intelligent-Based Modeling Techniques. DOI: 10.3390/agronomy15010181

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- Why is a glassy carbon boat preferred over an alumina crucible for Na3Cu4Se4? Ensuring Phase Purity in Flux Synthesis

- What are the main applications of laboratory furnaces? Unlock Precision Heat Processing for Your Lab

- Why are laboratory precision stirrers and heating devices essential for synthesizing magnetic precursor solutions?

- Why is a high-precision DC power supply necessary for PFS? Control Electric Fields for Perfect Plasma Sintering

- Why Is a High-Precision Heating and Stirring Platform Necessary for ZnO Sol-Gel Synthesis? Achieve Perfect Nanoparticles

- What roles do high-purity graphite dies play in SPS of Ti-6Al-4V? Mastering Efficient Composite Sintering

- What is the function of a Teflon-lined stainless steel autoclave in the hydrothermal synthesis of Bi2O3 precursors?

- How do vacuum systems assist in pure thin film growth? Enhance PLD Chemical Purity with Turbo-Molecular Pumps