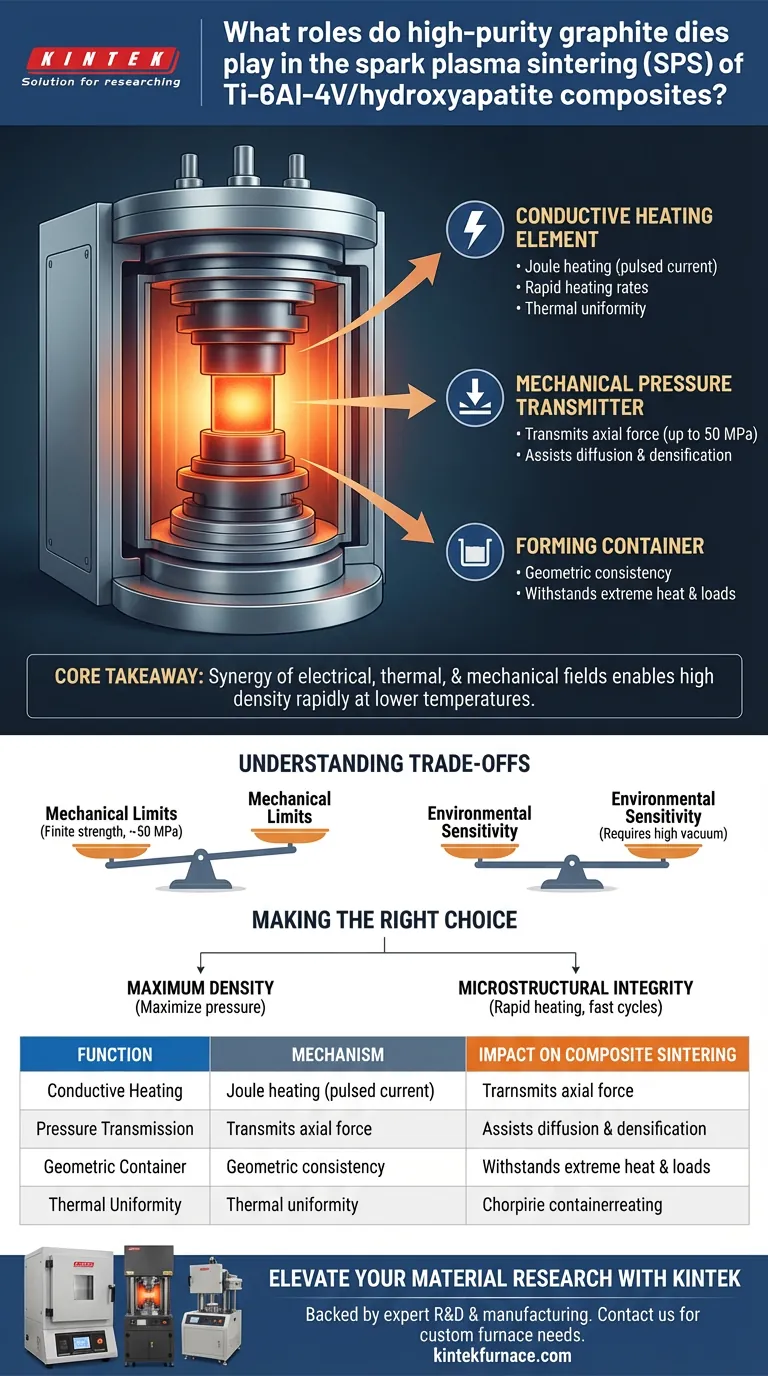

High-purity graphite dies serve as the fundamental processing interface during the Spark Plasma Sintering (SPS) of Ti-6Al-4V/hydroxyapatite composites. They perform three simultaneous and critical functions: acting as a geometric container for the powder, a conductive element that generates heat, and a mechanical transmitter of axial force.

Core Takeaway: By acting simultaneously as a heating element, a pressure vessel, and a shaping mold, the graphite die facilitates the coupling of electrical, thermal, and mechanical fields. This synergy allows Ti-6Al-4V/hydroxyapatite composites to achieve high density rapidly at lower temperatures than conventional sintering methods require.

The Multifaceted Role of the Graphite Die

The graphite die is not merely a passive mold; it is an active component of the machine's electrical and mechanical circuit. Its roles can be broken down into three distinct categories.

1. The Conductive Heating Element

In an SPS setup, the graphite die is an integral part of the electrical circuit.

It facilitates Joule heating. Because high-purity graphite has excellent electrical conductivity, it allows pulsed current to pass through the die assembly. This resistance generates intense heat (Joule heat) directly around the sample.

It ensures rapid heating rates. Unlike external heating elements used in conventional furnaces, the die enables the system to heat the sample very quickly. This rapid heating is crucial for minimizing grain growth while ensuring the material reaches the necessary sintering temperature.

It promotes thermal uniformity. The graphite distributes the generated heat evenly to the Ti-6Al-4V and hydroxyapatite powder mixture. Uniform thermal distribution is essential to prevent internal stresses or uneven densification within the composite.

2. The Mechanical Pressure Transmitter

The die works in tandem with the machine’s precision hydraulic system to densify the material.

It transmits axial force. The die assembly channels the force from the machine's rams directly into the powder mixture. This application of stable axial pressure mechanically compresses the particles, reducing void space.

It assists in diffusion. The pressure transmitted by the die—often up to 50 MPa—mechanically forces particles together. This proximity aids in diffusion and reaction at the particle boundaries, allowing densification to occur at lower thermal thresholds.

3. The Forming Container

At its most basic level, the die serves as the vessel that defines the geometry of the final product.

It maintains geometric consistency. The die holds the loose powder mixture in the desired shape (e.g., a 30 mm diameter cylinder) throughout the process.

It withstands extreme environments. The die must maintain its structural integrity while subjected to the simultaneous stress of high temperatures (often exceeding 1000°C) and high mechanical loads.

Understanding the Trade-offs

While high-purity graphite is the standard for SPS, it introduces specific operational constraints that must be managed.

Mechanical Limits. Graphite has a finite mechanical strength. While capable of withstanding significant force, there is a ceiling to the pressure it can handle—typically around 50 MPa for high-strength variants. Exceeding this limit to achieve higher density risks fracturing the die catastrophic failure.

Environmental Sensitivity. While the die facilitates the process, the environment is dictated by the vacuum system. Graphite does not protect the Ti-6Al-4V from oxidation on its own; it requires a high-vacuum environment to prevent the titanium alloy from absorbing oxygen and nitrogen, which would lead to embrittlement.

Making the Right Choice for Your Goal

The effectiveness of the graphite die depends on how you balance the parameters of pressure and heat.

- If your primary focus is Maximum Density: Maximize the pressure transmission capability of the die, keeping the axial load near the safe upper limit (e.g., 50 MPa) to mechanically force particle rearrangement.

- If your primary focus is Microstructural Integrity: Leverage the die's electrical conductivity to utilize rapid heating rates, minimizing the time the material spends at peak temperature to prevent excessive grain growth.

The graphite die is the critical link that transforms raw electrical and mechanical energy into a dense, high-performance composite.

Summary Table:

| Function | Mechanism | Impact on Composite Sintering |

|---|---|---|

| Conductive Heating | Joule heating via pulsed current | Enables rapid heating and minimizes grain growth |

| Pressure Transmission | Channels axial force (up to 50 MPa) | Enhances particle diffusion and densification |

| Geometric Container | High-temp structural mold | Maintains shape consistency under extreme conditions |

| Thermal Uniformity | Even heat distribution | Prevents internal stresses and uneven density |

Elevate Your Material Research with KINTEK

Unlock the full potential of your Spark Plasma Sintering (SPS) processes with high-performance laboratory solutions. Backed by expert R&D and manufacturing, KINTEK offers advanced Muffle, Tube, Rotary, Vacuum, and CVD systems, alongside customizable lab high-temp furnaces designed to meet your unique sintering requirements.

Whether you are developing Ti-6Al-4V composites or advanced bioceramics, our precision equipment ensures the thermal and mechanical control necessary for superior microstructural integrity.

Ready to optimize your lab's efficiency? Contact us today to discuss your custom furnace needs!

Visual Guide

References

- Reinhold Schneider, Christof Sommitsch. Partitioning Phenomena During the Heat Treatment of Martensitic Stainless Steels. DOI: 10.1515/htm-2025-0014

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Spark Plasma Sintering SPS Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

People Also Ask

- Why is modified PTFE used as a liner in high-pressure reactors for MoS2/C? Enhancing Purity and Yield.

- Why are lidded alumina crucibles required for LLZO sintering? Ensure High Ionic Conductivity and Phase Purity

- Why is an external cooling system vital for high-temperature furnace stability? Protect Your Research Integrity

- What is the primary function of a quartz tube in SnSe preparation? Ensure High-Purity Alloy Synthesis

- Why is a quartz reaction tube ideal for tubular carbon nanofibers? High-Purity Synthesis Solutions

- What function does a PTFE liner serve in NiWO4 synthesis? Ensure Purity & Prevent Corrosion in Hydrothermal Reactors

- What are the specific functions of high-purity graphite molds in SPS? Optimize Your Sintering Process

- Why is an air-cooled stainless steel sampling probe utilized? Ensure Accurate High-Temp Combustion Analysis