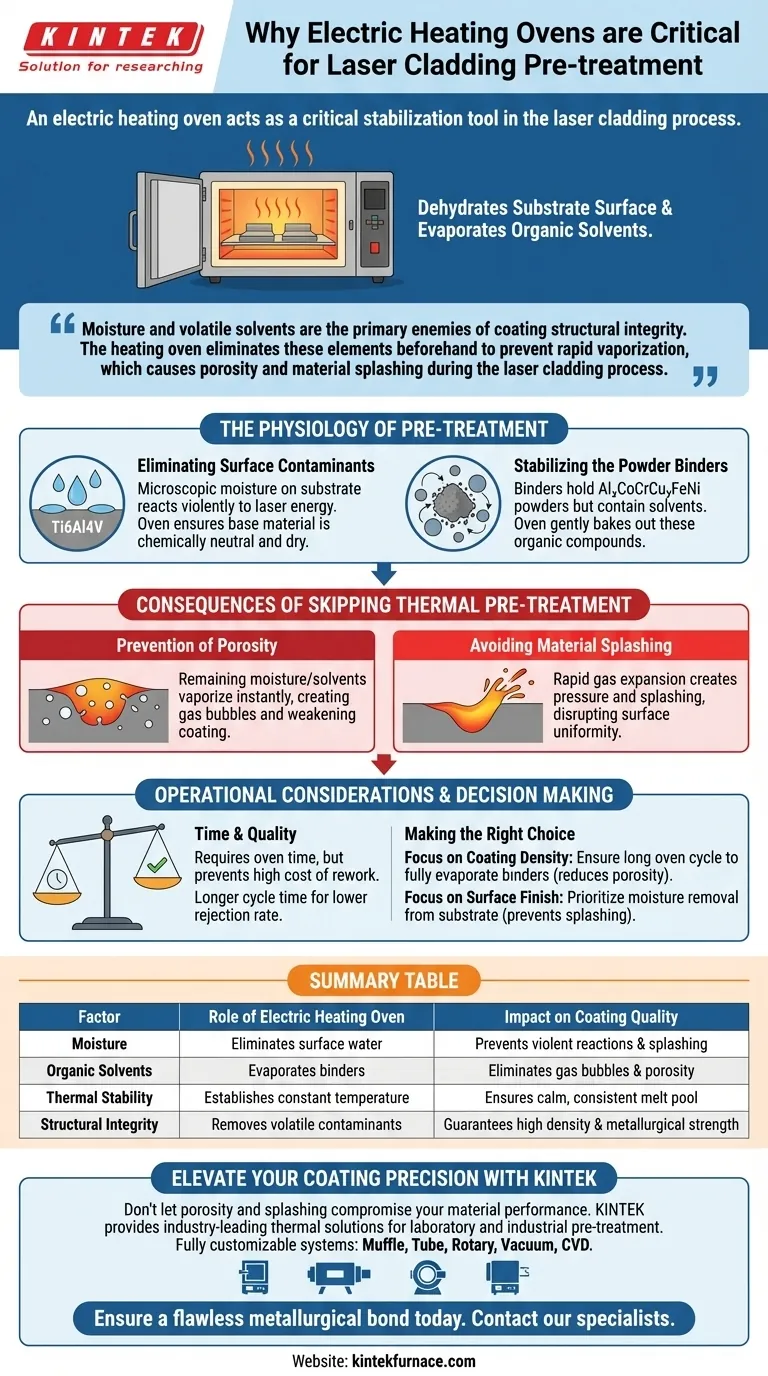

An electric heating oven acts as a critical stabilization tool in the laser cladding process by establishing a constant-temperature environment prior to laser application. Its primary function is to thoroughly dehydrate the substrate surface and evaporate organic solvents contained within the binders of the pre-placed AlxCoCrCuyFeNi powders.

Moisture and volatile solvents are the primary enemies of coating structural integrity. The heating oven eliminates these elements beforehand to prevent rapid vaporization, which causes porosity and material splashing during the laser cladding process.

The Physiology of Pre-treatment

Eliminating Surface Contaminants

The Ti6Al4V substrate often holds microscopic layers of moisture on its surface. If left untreated, this moisture reacts violently to the high energy of a laser.

The electric heating oven provides a stable thermal environment to drive this moisture off completely. This ensures the base material is chemically neutral and dry before the cladding begins.

Stabilizing the Powder Binders

Pre-placed AlxCoCrCuyFeNi powders rely on binders to hold their shape on the substrate. These binders typically contain organic solvents.

While necessary for application, these solvents become contaminants during melting. The oven functions to bake these organic compounds out of the powder bed gently.

Consequences of Skipping Thermal Pre-treatment

Prevention of Porosity

If moisture or solvents remain during laser cladding, they vaporize instantly upon contact with the laser beam.

This vaporization creates gas bubbles within the molten pool. As the metal solidifies, these bubbles become trapped, creating pores (porosity) that significantly weaken the coating.

Avoiding Material Splashing

The rapid expansion of trapped water or solvent into gas creates pressure. This often results in "splashing," where molten material is ejected from the melt pool.

Splashing disrupts the uniformity of the coating layer. By drying the sample first, the oven ensures a calm, consistent melt pool and a high-quality bond.

Operational Considerations

Balancing Time and Quality

Using an electric heating oven introduces an additional step to the manufacturing workflow. It requires time for the oven to reach the constant temperature and for the sample to dwell long enough for thorough drying.

However, this time investment is necessary to avoid the much higher cost of rework. The trade-off is a longer cycle time in exchange for a significantly lower rejection rate due to metallurgical defects.

Making the Right Choice for Your Goal

To maximize the performance of your AlxCoCrCuyFeNi coatings, consider the following regarding pre-treatment:

- If your primary focus is coating density: Ensure the oven cycle is long enough to fully evaporate all organic binders, as this directly reduces porosity.

- If your primary focus is surface finish: Prioritize moisture removal from the substrate to prevent splashing, which ruins the surface uniformity.

A dry, solvent-free interface is the only way to guarantee a metallurgical bond that withstands operational stress.

Summary Table:

| Factor | Role of Electric Heating Oven | Impact on Coating Quality |

|---|---|---|

| Moisture | Eliminates surface water from substrate | Prevents violent reactions and material splashing |

| Organic Solvents | Evaporates binders in pre-placed powders | Eliminates gas bubble formation and internal porosity |

| Thermal Stability | Establishes a constant-temperature environment | Ensures a calm, consistent melt pool for better bonding |

| Structural Integrity | Removes volatile contaminants | Guarantees high coating density and metallurgical strength |

Elevate Your Coating Precision with KINTEK

Don't let porosity and splashing compromise your material performance. KINTEK provides industry-leading thermal solutions designed for rigorous laboratory and industrial pre-treatment. Backed by expert R&D and manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all of which are fully customizable to meet your specific laser cladding requirements.

Ensure a flawless metallurgical bond today. Contact our specialists to find your ideal high-temperature furnace and experience the KINTEK advantage in precision and durability.

Visual Guide

References

- Ling Zhou, Yueyi Wang. Effect of Al/Cu Ratio on Microstructure and High-Temperature Oxidation Resistance of AlxCoCrCuyFeNi High-Entropy Alloy Coatings. DOI: 10.3390/jmmp9010013

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1200℃ Muffle Oven Furnace for Laboratory

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- How are vacuum furnaces used in chemical laboratories? Achieve High-Purity Results with Controlled Heating

- What key role does a laboratory vacuum drying oven play in cathode electrode processing? Ensure Peak Battery Stability

- Which industries commonly use vacuum arc furnaces and why? Unlock Ultra-Pure Metals for Aerospace, Medical, and Energy

- What are the main applications of vacuum furnaces? Achieve Superior Material Quality and Performance

- Why is a two-stage vacuum unit used in waste magnesium distillation? Optimize Pumping Speed and Process Stability

- What are the cooling methods for vacuum sintering furnaces? Optimize Your Material Properties

- What is vacuum sintering and its significance? Achieve Superior Material Performance

- How do laboratory vacuum furnaces achieve ultra-high vacuum levels? Unlock Pristine Processing Environments