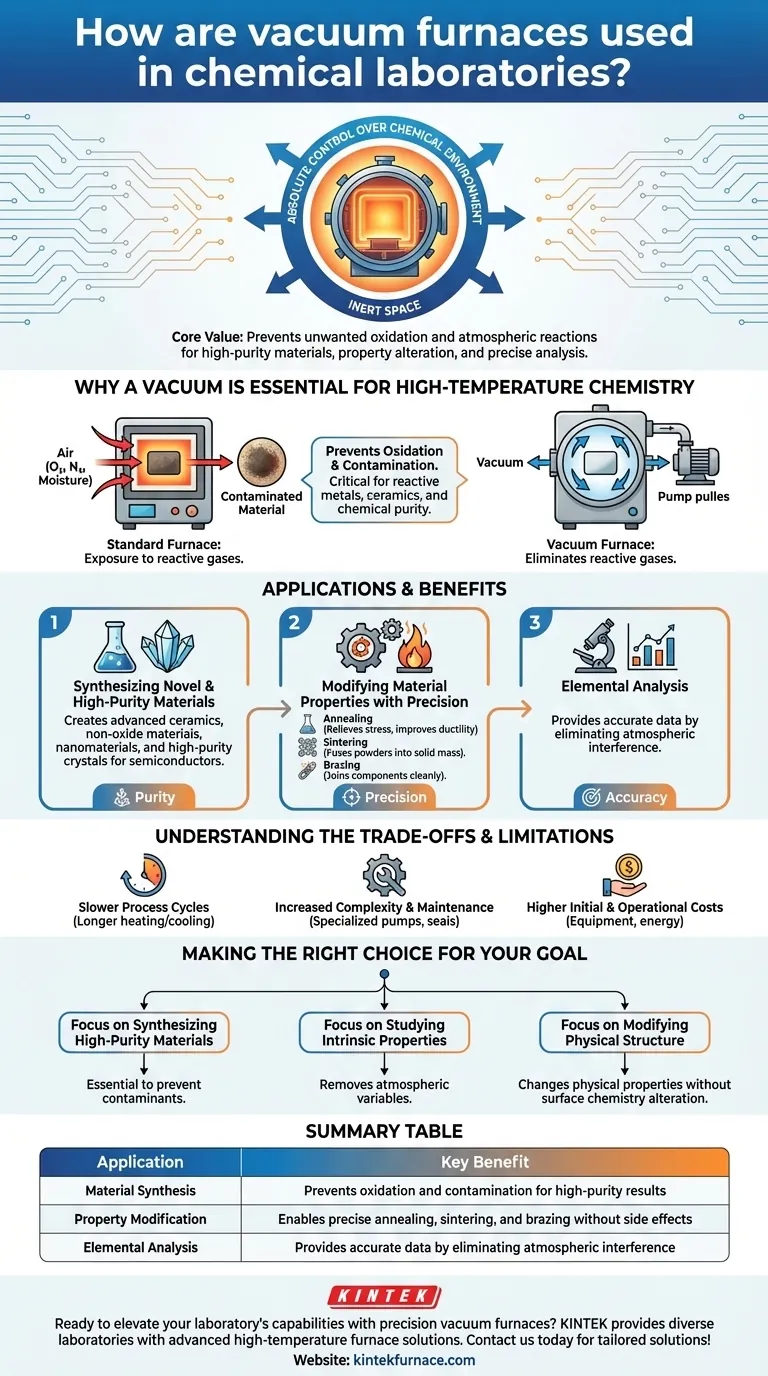

In a chemical laboratory, a vacuum furnace is used to heat materials to very high temperatures in a controlled, oxygen-free environment. This prevents unwanted oxidation and other atmospheric reactions, enabling chemists to synthesize high-purity materials, alter the physical properties of a substance without chemical contamination, and perform precise elemental analysis.

The core value of a vacuum furnace in chemistry is not just heating—it is absolute control over the chemical environment. By removing air and other reactive gases, the furnace creates an inert space where a material's intrinsic properties can be studied and modified with high precision.

Why a Vacuum is Essential for High-Temperature Chemistry

In a standard furnace, heating a material exposes it to oxygen, nitrogen, and moisture in the air. At high temperatures, these gases readily react with the sample, forming oxides and other impurities that compromise the material's integrity and experimental results.

A vacuum furnace eliminates this variable entirely.

Preventing Oxidation and Contamination

The primary function of the vacuum is to pump out the atmosphere. This prevents oxidation, which can fundamentally alter a material's chemical structure and properties.

This oxygen-free environment is critical for working with reactive metals, developing advanced ceramics, and ensuring the final product is chemically pure.

Synthesizing Novel and High-Purity Materials

Many advanced materials simply cannot be created in the presence of air. A vacuum furnace provides the ideal conditions for these sensitive processes.

Applications include the synthesis of advanced ceramics, non-oxide materials, and nanomaterials. It is also used for growing high-purity crystals for semiconductors and optical components.

Modifying Material Properties with Precision

Chemists use vacuum furnaces to intentionally alter a material's physical structure through heat treatment. The vacuum ensures these changes happen without unintended chemical side effects.

Key processes include:

- Annealing: Heating and slowly cooling a material (like a metal) to relieve internal stresses, soften it, and improve its ductility.

- Sintering: Fusing powdered materials together into a solid mass just below their melting point. This is used to create biocompatible implants and dense ceramic parts.

- Brazing: Joining two components together using a filler metal that melts and flows into the joint, all within a clean, inert environment.

Understanding the Trade-offs and Limitations

While powerful, vacuum furnaces are specialized tools with specific operational considerations. They are not a universal replacement for all laboratory heating needs.

Slower Process Cycles

Achieving a deep vacuum and then safely cooling the furnace chamber takes significantly more time than simply heating and cooling in an atmospheric furnace. This can limit sample throughput.

Increased Complexity and Maintenance

Vacuum furnaces involve sophisticated systems, including vacuum pumps, seals, and control instrumentation. These components require specialized knowledge to operate and maintain, adding a layer of complexity compared to conventional ovens.

Higher Initial and Operational Costs

The equipment required for creating and maintaining a high-vacuum environment is inherently more expensive than standard laboratory furnaces. This includes the cost of the furnace itself, the vacuum pumps, and energy consumption.

Making the Right Choice for Your Goal

The decision to use a vacuum furnace should be driven by the specific requirements of your chemical experiment or material processing task.

- If your primary focus is synthesizing high-purity materials: A vacuum furnace is essential to prevent the formation of oxides and other contaminants that are unavoidable in an air atmosphere.

- If your primary focus is studying a material's intrinsic properties: Using a vacuum furnace removes atmospheric variables, ensuring your analysis reflects the material itself, not its reaction with air.

- If your primary focus is modifying physical structure (e.g., annealing): The vacuum ensures you are only changing the material's physical properties, like stress and ductility, without altering its surface chemistry.

Ultimately, a vacuum furnace empowers you to isolate your chemical system from the reactive world, enabling a level of precision and purity that is otherwise unattainable.

Summary Table:

| Application | Key Benefit |

|---|---|

| Material Synthesis | Prevents oxidation and contamination for high-purity results |

| Property Modification | Enables precise annealing, sintering, and brazing without side effects |

| Elemental Analysis | Provides accurate data by eliminating atmospheric interference |

Ready to elevate your laboratory's capabilities with precision vacuum furnaces? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet your unique experimental requirements. Contact us today to discuss how our tailored solutions can enhance your material synthesis and analysis processes!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- How does vacuum heat treatment improve mechanical properties of metals? Enhance Strength and Durability

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What is the heat treatment in a vacuum furnace? Achieve Superior Metallurgical Properties

- Why use a vacuum furnace? Achieve Unparalleled Material Purity and Process Control

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion