A resistance furnace equipped with silicon molybdenum rod heating elements is required to provide the precise high-temperature stability needed for material homogenization. This specific setup enables the reheating of pre-melted desulfurizers to 1400°C and maintains that temperature for 30 minutes, ensuring the internal phase structure reaches a critical equilibrium state.

The core value of using silicon molybdenum rods lies in their ability to maintain superior stability at high temperatures. This ensures that the desulfurizer simulates actual hot metal desulfurization conditions, effectively eliminating the non-uniform phase distribution caused by prior cooling rate variations.

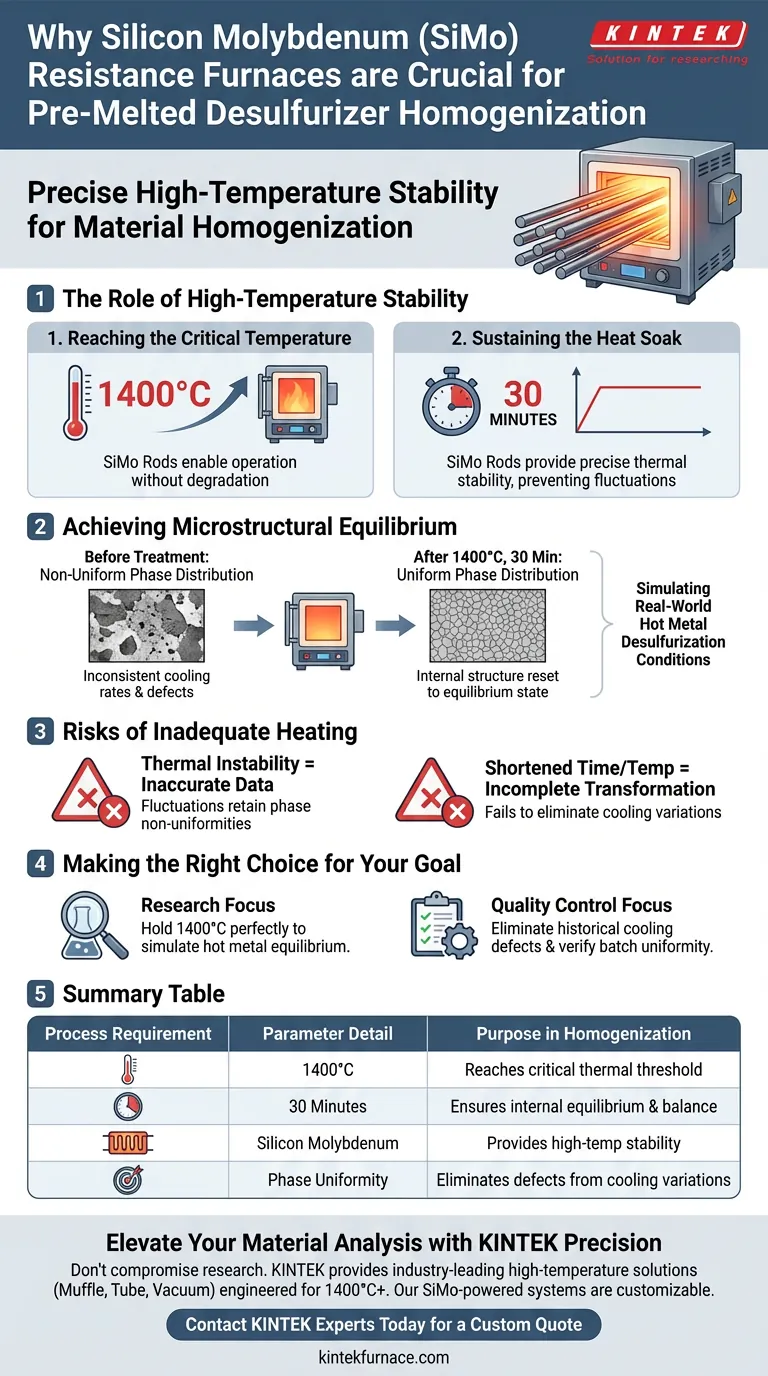

The Role of High-Temperature Stability

Reaching the Critical Temperature

To effectively homogenize pre-melted desulfurizers, the equipment must reliably reach 1400°C.

Standard heating elements often struggle to maintain consistency at this extreme heat. Silicon molybdenum rods are specifically chosen because they can operate effectively in this thermal range without degrading the process environment.

Sustaining the Heat Soak

Achieving the target temperature is only the first step; maintaining it is equally vital.

The process requires a sustained hold time of 30 minutes at 1400°C. The silicon molybdenum elements provide the thermal stability necessary to hold this temperature with high precision, preventing fluctuations that could disrupt the chemical balancing act occurring within the material.

Achieving Microstructural Equilibrium

Correcting Cooling Rate Defects

During the initial production of desulfurizers, differences in cooling rates often lead to inconsistent internal structures.

These variations result in a non-uniform phase distribution, which compromises the material's performance. The resistance furnace treats this by reheating the material, effectively "resetting" its internal structure to a uniform state.

Simulating Real-World Conditions

The ultimate goal of this heating process is to mimic the conditions of hot metal desulfurization.

By forcing the internal phase structure to reach an equilibrium state, the furnace ensures that the test material behaves exactly as it would in a real-world industrial application. This predictive accuracy is impossible without the stable thermal environment provided by the heating elements.

Understanding the Risks of Inadequate Heating

The Cost of Thermal Instability

If the heating environment fluctuates even slightly, the material may fail to reach true equilibrium.

Without the stability provided by silicon molybdenum rods, you risk retaining the original phase non-uniformities. This leads to data that does not accurately represent the desulfurizer's performance in actual hot metal scenarios.

Time vs. Quality

The requirement of a 30-minute hold time at 1400°C is a significant energy and time investment.

However, shortening this duration or lowering the temperature to save resources will result in an incomplete phase transformation. The trade-off is clear: absolute adherence to these parameters is necessary to eliminate the history of cooling rate variations.

Making the Right Choice for Your Goal

To ensure your desulfurization analysis is accurate, apply the following guidelines:

- If your primary focus is material research: Ensure your furnace can hold 1400°C without fluctuation to perfectly simulate the equilibrium state of hot metal desulfurization.

- If your primary focus is quality control: Use this specific heating method to eliminate historical cooling defects and verify the uniformity of your pre-melted batches.

Precision in heating elements is the only way to guarantee precision in material performance.

Summary Table:

| Process Requirement | Parameter Detail | Purpose in Homogenization |

|---|---|---|

| Target Temperature | 1400°C | Reaches the critical thermal threshold for phase reset |

| Soak Duration | 30 Minutes | Ensures internal equilibrium and chemical balance |

| Heating Element | Silicon Molybdenum | Provides high-temperature stability without degradation |

| Material Goal | Phase Uniformity | Eliminates defects caused by previous cooling variations |

Elevate Your Material Analysis with KINTEK Precision

Don't let thermal instability compromise your desulfurization research. KINTEK provides industry-leading high-temperature solutions, including Muffle, Tube, and Vacuum furnaces specifically engineered for demanding 1400°C+ processes. Our systems, powered by high-performance silicon molybdenum rods and backed by expert R&D, are fully customizable to meet your unique lab requirements.

Eliminate phase non-uniformity and simulate real-world conditions with confidence.

Contact KINTEK Experts Today for a Custom Quote

Visual Guide

References

- Jyun-Ming Shen, Weite Wu. Effects of Different CaO/Al2O3 Ratios on the Phase Composition and Desulfurization Ability of CaO-Based Desulfurizers in Hot Metal. DOI: 10.3390/met14030363

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What are ceramic heating elements and what are their key characteristics? Discover High-Performance Heating Solutions

- What are resistance heating elements made of and where are they used? Discover Materials for Efficient Heat Generation

- Why is silicon carbide used in corrosive industrial applications? Unlock Superior Durability in Harsh Environments

- What factors affect the lifespan of MoSi2 heating elements? Maximize Longevity with Proper Care

- Why is high temperature stability important for graphite heating elements? Ensure Reliable Performance in Extreme Heat

- What recent advancements have been made in Molybdenum Disilicide (MoSi2) element technology? Tailored Solutions for Extreme Heat

- What is the basic principle behind the working of heating elements? Discover Joule Heating for Precise Thermal Control

- Why must insulating alumina powder be used to cover Ag2S1-xTex samples during PCS? Protect Superionic Integrity