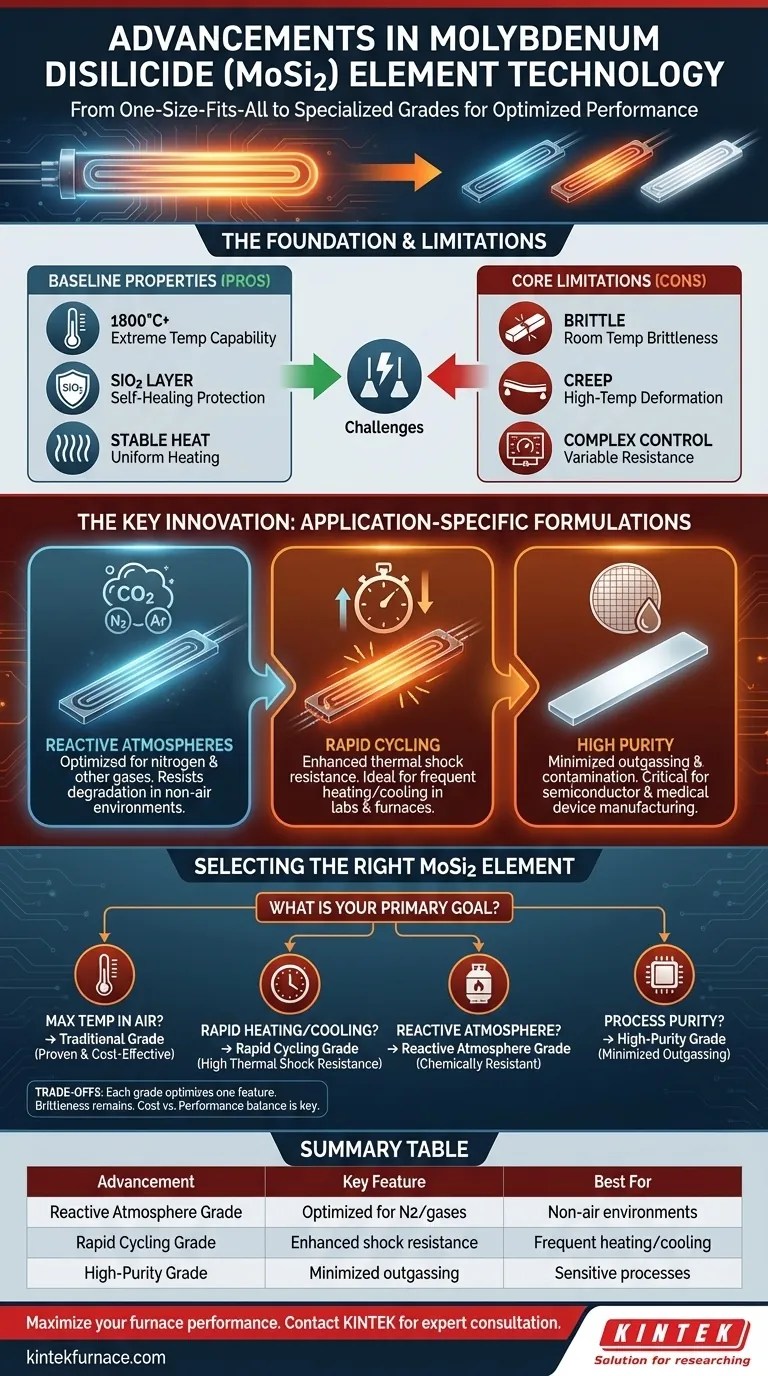

Recent advancements in Molybdenum Disilicide (MoSi2) heating element technology have moved beyond a one-size-fits-all approach. The key innovation is the development of specialized grades, each formulated to optimize performance and longevity in specific, challenging industrial applications, such as reactive atmospheres or processes with rapid temperature cycling.

The core evolution in MoSi2 technology is not a fundamental change to the material itself, but rather the strategic creation of application-specific elements. This allows users to select a grade that directly addresses the unique demands and failure points of their high-temperature process.

The Foundation: Why MoSi2 Is a High-Temperature Standard

Before exploring the advancements, it's crucial to understand the baseline properties that make MoSi2 a preferred choice for extreme heat applications.

Extreme Temperature Capability

MoSi2 elements are engineered for the highest temperature processes, capable of stable operation up to 1800°C (3272°F) or even higher in certain conditions. This makes them essential for manufacturing advanced ceramics, specialty glass, and high-purity metals.

The Self-Healing Protective Layer

The material's exceptional resistance to oxidation comes from a regenerative layer of silica (SiO2) that forms on its surface at high temperatures. This protective film prevents the underlying material from degrading in oxidizing atmospheres.

Stable and Uniform Heating

MoSi2 elements provide highly stable and uniform heat, which is critical for ensuring process consistency and product quality in sensitive industrial applications like high-temperature sintering.

The Core Limitations of Traditional MoSi2

While powerful, the material has inherent characteristics that create challenges. Recent advancements are primarily focused on mitigating these specific issues.

Brittleness at Room Temperature

MoSi2 is a cermet (ceramic-metallic composite) that is very brittle at ambient temperatures. This necessitates careful handling during installation and maintenance to prevent fractures.

High-Temperature Creep

Under sustained high temperatures and mechanical stress, MoSi2 elements can slowly deform over time. This phenomenon, known as creep, can eventually lead to element failure.

Complex Power Control Requirements

A significant challenge is that the electrical resistance of MoSi2 changes dramatically as it heats up. This requires sophisticated power control systems to deliver consistent power and prevent overheating or inefficiency.

The Key Advancement: Application-Specific Formulations

Continuous manufacturing improvements have resulted in new grades of MoSi2, each tailored to thrive under specific operational stresses.

Operation in Reactive Atmospheres

New formulations are available that are optimized to function at high temperatures in reactive atmospheres, such as nitrogen, where standard elements might degrade more quickly.

Enhanced Durability for Rapid Cycling

Elements have been developed specifically for laboratory and sintering furnaces that undergo frequent and rapid heating and cooling. These grades offer improved resistance to the thermal shock that can cause premature failure.

Purity for Contamination-Sensitive Processes

For industries like semiconductor or medical device manufacturing, specialized high-purity MoSi2 elements are now available. These are designed to minimize outgassing and prevent contamination of the product or process chamber.

Understanding the Trade-offs

Selecting an advanced MoSi2 element requires a clear understanding of your specific process needs, as there is no single best solution.

No "One-Size-Fits-All" Element

An element optimized for rapid cycling may not have the same maximum temperature rating as one designed for steady-state operation in air. Each specialized grade involves engineering trade-offs to enhance one performance characteristic.

The Fundamental Properties Remain

These advancements mitigate, but do not eliminate, the core properties of MoSi2. For example, even specialized elements remain brittle at room temperature and require careful handling.

Cost vs. Performance

Specialized, high-performance elements typically command a higher price. The goal is to match the investment to the specific problem you are trying to solve, such as reducing downtime or improving product yield.

Selecting the Right MoSi2 Element for Your Process

Your specific operational goal is the most important factor in choosing the correct MoSi2 element technology.

- If your primary focus is maximum temperature in a standard air atmosphere: A traditional, high-quality MoSi2 grade is often the most proven and cost-effective choice.

- If your primary focus is rapid heating and cooling cycles: Seek out elements specifically marketed for high thermal shock resistance to ensure longer operational life.

- If your primary focus is operating in a reactive or non-air atmosphere: You must select a specialized grade engineered to withstand the specific chemical environment of your process.

- If your primary focus is process purity and avoiding contamination: Invest in a high-purity grade designed to minimize outgassing and protect your sensitive products.

Matching the specific MoSi2 grade to your unique application is the key to unlocking maximum performance, reliability, and efficiency in your high-temperature operations.

Summary Table:

| Advancement | Key Feature | Best For |

|---|---|---|

| Reactive Atmosphere Grade | Optimized for nitrogen & other gases | Processes in non-air environments |

| Rapid Cycling Grade | Enhanced thermal shock resistance | Labs & furnaces with frequent heating/cooling |

| High-Purity Grade | Minimized outgassing & contamination | Semiconductor & medical device manufacturing |

Maximize the performance and lifespan of your high-temperature furnace. The right MoSi2 element is critical for your specific application. Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD furnace systems. Our MoSi2 elements are customizable for your unique needs in reactive atmospheres, rapid cycling, or high-purity processes.

Contact our heating experts today for a consultation and ensure your furnace operates at peak efficiency.

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What are the advantages of silicon carbide heating elements in dental furnaces? Boost Zirconia Sintering Quality

- What heating elements are used in high-temperature tube furnaces? Discover SiC and MoSi2 for Extreme Heat

- What is silicon carbide used for in heating applications? Discover Its High-Temperature Durability

- What is the temperature range for silicon carbide heating elements? Unlock High-Temp Performance from 600°C to 1625°C

- What parameters does the IEC standard specify for heating elements? Ensure Safety and Performance