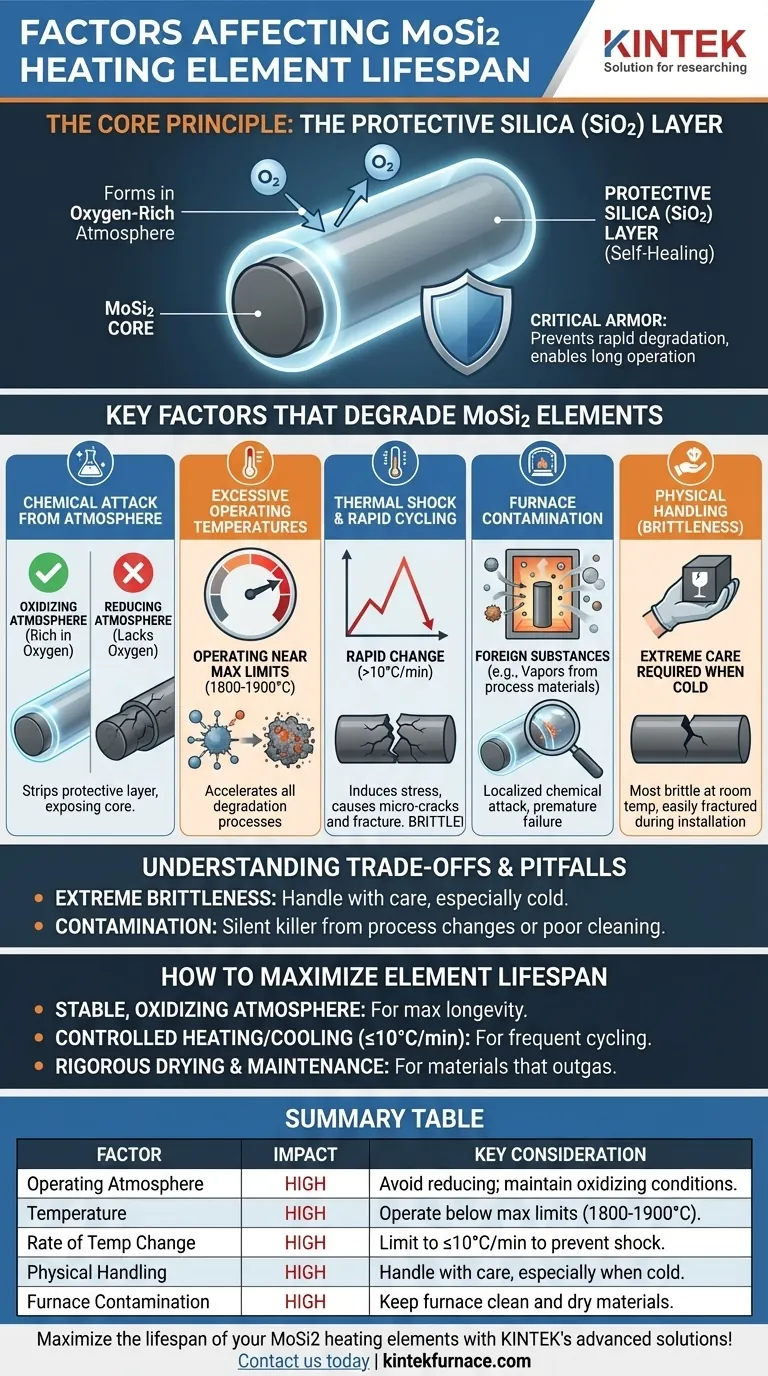

The lifespan of a MoSi2 heating element is primarily determined by its operating atmosphere, temperature, rate of temperature change, and physical handling. These elements achieve their longevity by forming a protective silica layer in an oxygen-rich environment, and any factor that compromises this layer will drastically shorten the element's operational life.

While known for longevity, a MoSi2 element's lifespan is not guaranteed. It depends entirely on maintaining the integrity of its self-forming protective silica (SiO2) layer, which is vulnerable to specific operational conditions and chemical attacks.

The Core Principle: The Protective Silica (SiO2) Layer

To understand what shortens an element's life, you must first understand what makes it last. The exceptional lifespan of Molybdenum Disilicide (MoSi2) elements in high-temperature applications is not inherent to the material itself, but to its ability to protect itself.

How the Protective Layer Forms

When a MoSi2 element is heated in an atmosphere containing oxygen, the silicon in the element reacts with the oxygen to form a thin, non-porous, and self-healing layer of quartz glass (silica, or SiO2) on its surface.

This process is a form of passive oxidation, creating a barrier that encases the core material.

Why This Layer is Critical

This silica layer is the element's armor. It prevents the underlying MoSi2 from oxidizing further, which would lead to its rapid degradation and failure. This "auto-repair" function allows for long, continuous operation at extreme temperatures.

Key Factors That Degrade MoSi2 Elements

An element's life is shortened whenever the integrity of its protective silica layer is compromised. The primary threats are chemical, thermal, and physical.

Chemical Attack from the Atmosphere

The single greatest threat is a reducing atmosphere, which is an environment lacking free oxygen. Such an atmosphere will chemically strip away the protective SiO2 layer, leaving the core MoSi2 material exposed.

Switching between oxidizing (oxygen-rich) and reducing environments is particularly damaging, as the element is repeatedly stripped of its protection and forced to consume its own silicon to regrow it.

Excessive Operating Temperatures

While MoSi2 elements are rated for very high temperatures (up to 1800-1900°C on the element surface), consistently operating at the absolute maximum limit will accelerate degradation and shorten lifespan.

Higher temperatures increase the rate of all chemical reactions, including those that can slowly compromise the element over time, even in a proper atmosphere.

Thermal Shock and Rapid Cycling

MoSi2 elements are ceramic-metallic composites and are inherently brittle, especially at room temperature. They cannot tolerate rapid temperature changes.

Heating or cooling too quickly induces internal stresses, leading to micro-cracks or outright fracture. A maximum recommended rate is often around 10°C per minute.

Furnace Contamination

Any foreign substance that can react with the silica layer at high temperatures poses a threat. This includes vapors from materials being processed in the furnace.

For example, improperly dried zirconia colorants or other volatile compounds can outgas, creating a localized chemical attack on the element's surface and leading to premature failure.

Understanding the Trade-offs and Pitfalls

MoSi2 elements offer incredible performance, but this comes with specific operational requirements that cannot be ignored. Understanding these trade-offs is key to avoiding costly mistakes.

Extreme Brittleness Requires Careful Handling

The material's brittleness is most pronounced when it is cold. Elements must be handled with extreme care during installation and maintenance to prevent fractures.

Once at operating temperature, they are more ductile, but the initial installation is a critical phase where damage often occurs.

Contamination Is a Silent Killer

The long life of these elements can lead to complacency. However, seemingly minor changes in process, such as using a new coating or failing to properly clean the furnace chamber, can introduce contaminants that silently degrade the elements.

Proper furnace maintenance and rigorous drying of all materials placed inside are not optional best practices; they are essential for element longevity.

How to Maximize Element Lifespan

Your operational choices directly impact the return on your investment. Use these guidelines to align your procedures with your goals.

- If your primary focus is maximum longevity: Prioritize stable temperatures and a clean, consistently oxidizing atmosphere to preserve the protective silica layer.

- If your process involves frequent cycling: Adhere strictly to controlled heating and cooling rates (e.g., under 10°C per minute) to prevent thermal shock.

- If you work with materials that outgas: Implement rigorous drying protocols and furnace maintenance schedules to prevent chemical contamination.

Proactive control over the furnace environment is the key to unlocking the full potential of MoSi2 elements for long-term, reliable service.

Summary Table:

| Factor | Impact on Lifespan | Key Consideration |

|---|---|---|

| Operating Atmosphere | High | Avoid reducing atmospheres; maintain oxidizing conditions for SiO2 layer protection |

| Temperature | High | Operate below max limits (1800-1900°C) to slow degradation |

| Rate of Temperature Change | High | Limit to ≤10°C/min to prevent thermal shock and cracking |

| Physical Handling | High | Handle with care, especially when cold, to avoid fractures |

| Furnace Contamination | High | Keep furnace clean and dry materials to prevent chemical attacks |

Maximize the lifespan of your MoSi2 heating elements with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise fit for your unique experimental needs, enhancing durability and performance. Contact us today to discuss how we can support your lab's efficiency and reliability!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What is the temperature range for silicon carbide heating elements? Unlock High-Temp Performance from 600°C to 1625°C

- What is the operating temperature of SiC? Unlock Reliable Performance Up to 1600°C

- What parameters does the IEC standard specify for heating elements? Ensure Safety and Performance

- What temperature ranges are recommended for SiC versus MoSi2 heating elements? Optimize Your Furnace Performance

- What is the difference between SiC and MoSi2? Choose the Right High-Temp Heating Element