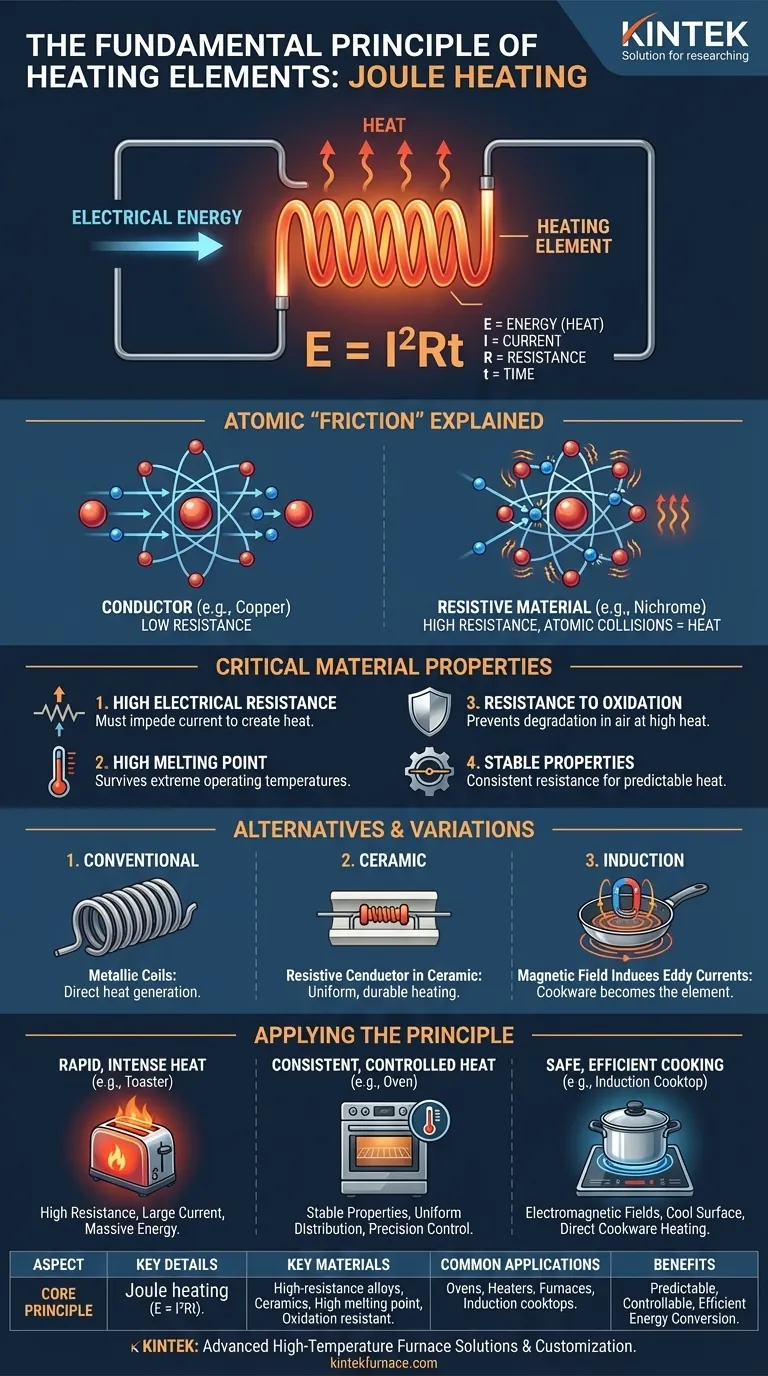

At its core, a heating element works by converting electrical energy directly into heat. This is achieved by passing an electric current through a material specifically chosen for its high electrical resistance. This fundamental principle, known as Joule heating or resistive heating, is governed by the formula E = I²Rt, where the energy (heat) produced is a product of the current (I), resistance (R), and time (t).

A heating element is essentially a carefully engineered resistor. By forcing electricity through a material that deliberately impedes its flow, the resulting "friction" at an atomic level generates predictable, controllable heat on demand.

The Fundamental Principle: Joule Heating

The science behind a heating element is elegant in its simplicity. It's all about managing the flow of electricity to intentionally create heat.

Electricity Meets Resistance

An electrical current is the flow of electrons through a conductor. In an ideal conductor, like a copper wire, electrons flow with very little opposition. A heating element, however, is made from a material with high electrical resistance, acting as a bottleneck that makes it difficult for the electrons to pass through.

The Atomic "Friction"

As electrons are forced through this resistive material, they collide with the atoms of the material. Each collision transfers kinetic energy from the electron to the atom, causing the atom to vibrate more intensely. This increased atomic vibration is what we perceive and measure as heat.

The Formula for Heat

The amount of heat generated is predictable. The relationship E = I²Rt shows that the heat energy produced is directly proportional to the square of the current and the resistance. Doubling the current, for example, quadruples the heat output, which is why these elements are so effective.

What Makes a Good Heating Element?

Not just any resistive material will work. Materials for heating elements are selected based on a few critical properties that allow them to function reliably and efficiently at high temperatures.

High Electrical Resistance

The primary job of the element is to generate heat, so it must effectively resist the flow of current. Materials like nichrome (a nickel-chromium alloy) are common because they have a much higher resistance than copper or aluminum.

High Melting Point

A heating element is designed to get very hot. The material must have a melting point far above its maximum operating temperature to avoid destroying itself during use.

Resistance to Oxidation

At high temperatures, many materials react with oxygen in the air, a process called oxidation. This can cause the element to become brittle and fail. Heating element alloys are specifically designed to form a stable, protective layer of oxide that prevents further degradation.

Stable Properties

For consistent performance, the element's resistance should remain relatively stable across a wide range of temperatures. This ensures that the heat output is predictable and controllable, which is crucial for appliances like ovens and heaters.

Understanding Alternatives and Variations

While Joule heating is the most common principle, its application and alternatives are important to understand.

Conventional vs. Ceramic Elements

Traditional heating elements are often metallic coils. Ceramic heating elements, on the other hand, embed a resistive conductor within a ceramic material. The ceramic offers excellent thermal conductivity for uniform heating and acts as a durable, protective insulator, often leading to longer-lasting performance.

The Exception: Induction Heating

Induction heating operates on a different principle. Instead of the element itself getting hot, it uses a variable magnetic field to induce electrical currents (called eddy currents) directly within a conductive pot or pan. The pan's own internal resistance to these currents then creates heat via the Joule effect. In this case, the cookware itself becomes the heating element.

Applying This Principle to Your Goal

Understanding this core concept allows you to see how different devices are engineered for specific heating tasks.

- If your primary focus is rapid, intense heat (like in a toaster or hair dryer): The design uses an element with high resistance and a large current to quickly generate a massive amount of thermal energy.

- If your primary focus is consistent, controlled heat (like in an oven or water heater): The system uses elements designed for stable properties and uniform heat distribution, typically paired with a thermostat to maintain a precise temperature.

- If your primary focus is safe, efficient stovetop cooking (like on an induction cooktop): The technology leverages electromagnetic fields to turn the cookware itself into the source of heat, leaving the cooktop surface relatively cool.

By mastering the simple principle of electrical resistance, we gain precise and on-demand control over heat in countless applications.

Summary Table:

| Aspect | Key Details |

|---|---|

| Core Principle | Joule heating: converts electrical energy to heat via resistance (E = I²Rt). |

| Key Materials | High-resistance alloys (e.g., nichrome), ceramics; require high melting point, oxidation resistance. |

| Common Applications | Ovens, water heaters, toasters, lab furnaces; includes induction heating for cooktops. |

| Benefits | Predictable heat output, controllable temperature, efficient energy conversion for various uses. |

Ready to elevate your laboratory's heating capabilities? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how our tailored heating solutions can enhance your efficiency and precision!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?

- What is the role of vacuum pumps in a vacuum heat treatment furnace? Unlock Superior Metallurgy with Controlled Environments

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity

- How does the ultra-low oxygen environment of vacuum sintering affect titanium composites? Unlock Advanced Phase Control