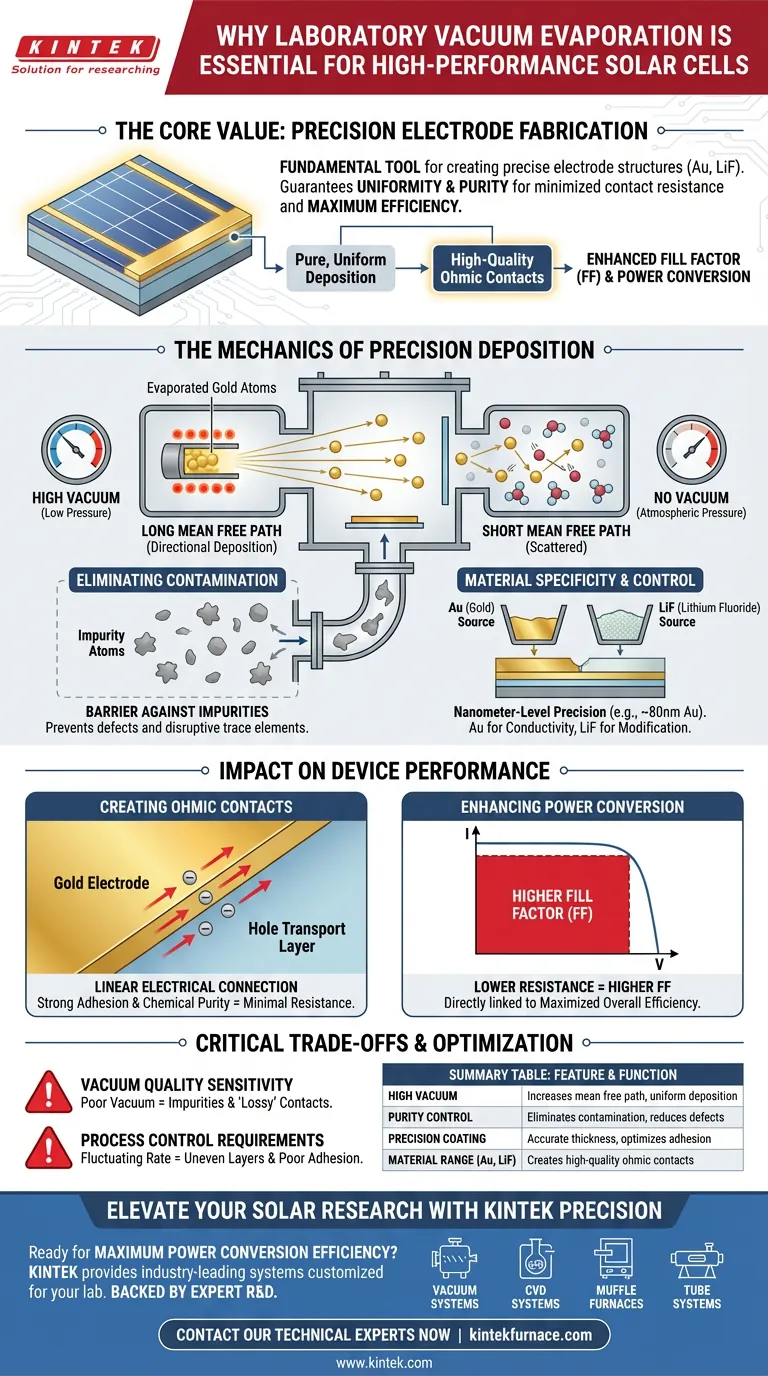

A laboratory vacuum evaporation system is the fundamental tool required to fabricate the precise electrode structures necessary for high-performance solar cells. Specifically, it allows for the thermal evaporation of gold (Au) and lithium fluoride (LiF) modification layers under high-vacuum conditions. This equipment is essential because it guarantees the uniformity and purity of the metal deposition, which is the only way to minimize contact resistance and ensure the device functions efficiently.

The core value of this system lies in its ability to create high-quality ohmic contacts through pure, uniform deposition; this directly enhances the Fill Factor (FF) and maximizes the overall power conversion efficiency of the solar cell.

The Mechanics of Precision Deposition

To understand why this system is non-negotiable, one must look at the physical behavior of atoms during the coating process.

The Role of High Vacuum

The system operates by creating an extremely low-pressure environment. In this state, the "mean free path" of the evaporated atoms increases significantly.

This means gold atoms can travel from the source to the device surface without colliding with gas molecules. This directional path is critical for ensuring the electrode is deposited exactly where it is needed without scattering.

Eliminating Contamination

The high-vacuum state serves a dual purpose: it acts as a barrier against contamination.

By removing atmospheric gases, the system prevents impurity atoms from becoming trapped within the electrode layer. Even trace impurities can disrupt the electrical properties of the material, so this purity is essential for performance.

Material Specificity

The system is specifically optimized for depositing materials like gold (Au) and lithium fluoride (LiF).

Gold is selected for its superior electrical conductivity, while LiF acts as a crucial modification layer. The thermal evaporation process allows these distinct materials to be layered with nanometer-level precision.

Impact on Device Performance

The physical deposition process translates directly into the electrical metrics of the solar cell.

Creating Ohmic Contacts

The primary goal of the electrode is to extract current from the device. To do this efficiently, the interface between the electrode and the semiconductor must be an ohmic contact.

The vacuum system ensures that the gold electrode (often around 80 nm thick) adheres perfectly to the hole transport layer. This strong adhesion and chemical purity create a linear electrical connection with minimal resistance.

Enhancing Power Conversion

Minimizing contact resistance has a cascading effect on the solar cell's output.

Lower resistance leads to a higher Fill Factor (FF), which is a measure of the "squareness" of the current-voltage curve. A higher FF is mathematically tied to higher overall power conversion efficiency, particularly in complex architectures like triple-junction solar cells.

Understanding the Critical Trade-offs

While vacuum evaporation is essential for high performance, it introduces specific challenges that must be managed.

Sensitivity to Vacuum Quality

The quality of the electrode is entirely dependent on the quality of the vacuum.

If the pressure is not sufficiently low, the mean free path shortens, and impurities will act as defects in the electrode. This results in "lossy" contacts that dissipate power rather than extracting it.

Process Control Requirements

Achieving an optimal 80 nm thickness requires precise thermal control.

Fluctuations in evaporation rate can lead to uneven layers. An uneven layer may fail to provide adequate coverage or adhesion, compromising the mechanical stability of the contact.

Optimizing Your Fabrication Strategy

To ensure your solar cell preparation yields the best results, consider how these variables align with your specific objectives.

- If your primary focus is maximizing efficiency: Prioritize the highest possible vacuum levels to eliminate impurities and maximize the Fill Factor (FF).

- If your primary focus is mechanical stability: Focus on the thermal control of the evaporation rate to ensure strong adhesion between the gold electrode and the hole transport layer.

The vacuum evaporation system is not just a coating tool; it is the bridge between raw materials and a functioning, high-efficiency energy device.

Summary Table:

| Feature | Function in Solar Cell Fabrication | Impact on Performance |

|---|---|---|

| High Vacuum | Increases mean free path of atoms | Ensures uniform, directional deposition |

| Purity Control | Eliminates atmospheric contamination | Reduces defects and electrical losses |

| Precision Coating | Accurate thickness (e.g., 80nm Au) | Optimizes adhesion and conductivity |

| Material Range | Thermal evaporation of Au and LiF | Creates high-quality ohmic contacts |

Elevate Your Solar Research with KINTEK Precision

Ready to achieve maximum power conversion efficiency? KINTEK provides industry-leading laboratory vacuum systems tailored for high-performance electrode preparation. Backed by expert R&D and manufacturing, we offer a comprehensive range of customizable solutions—including Vacuum, CVD, Muffle, and Tube systems—designed to meet the unique needs of your lab.

Maximize your Fill Factor and ensure pure, uniform deposition today. Contact our technical experts now to find the perfect high-temperature furnace or vacuum system for your research.

Visual Guide

References

- Hang Hu, Ulrich W. Paetzold. Triple-junction perovskite–perovskite–silicon solar cells with power conversion efficiency of 24.4%. DOI: 10.1039/d3ee03687a

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- MPCVD Machine System Reactor Bell-jar Resonator for Lab and Diamond Growth

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

People Also Ask

- Why is thermal growth oxidation preferred for SiO2 gate dielectrics? Superior Quality for a-IGZO TFTs

- Why is a vacuum drying oven essential in the synthesis of CuCl nano-arrays? Protect Purity and Performance

- What are the temperature ranges for low, medium, and high-temperature industrial heating processes? Optimize Your Process with KINTEK

- What role does active carbon play in CaS:Eu2+ phosphor synthesis? Key to Activating High-Efficiency Luminescence

- What is the significance of using a hydrogen etching process in a reaction chamber? Mastering SiC Surface Preparation

- Why is a high-precision substrate heating system required for BST thin films? Achieve Crystal Growth Success

- What is a benchtop industrial oven? Maximize Space and Efficiency in Your Lab

- How does an industrial vacuum drying oven affect electrode performance? Optimize Sodium-Ion Battery Stability