Precision control over moisture content is the defining factor in successful hard carbon preparation. A high-temperature vacuum drying oven is necessary to treat precursors because it thoroughly removes deep-seated moisture and volatile solvents from the material's pores, specifically at temperatures around 105 °C. This process is critical to ensure the physical stability of the material before it undergoes extreme heat in later stages.

Core Takeaway

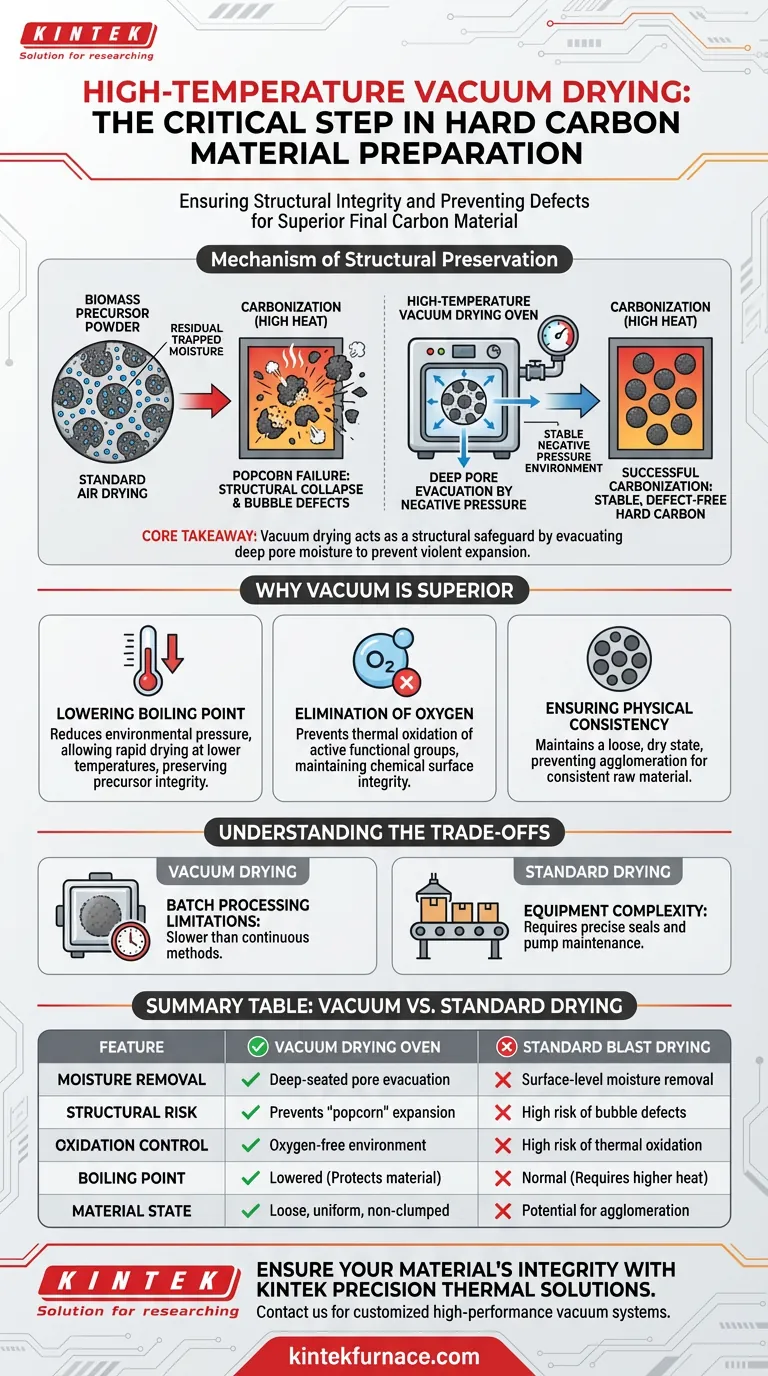

The vacuum drying oven acts as a structural safeguard. By using negative pressure to evacuate moisture from deep pores, it prevents the violent expansion of trapped water during subsequent high-temperature carbonization, thereby avoiding structural collapse and the formation of bubble defects.

The Mechanism of Structural Preservation

Deep Pore Evacuation

Standard air drying often leaves residual moisture trapped deep within the microscopic pores of biomass powder.

A vacuum oven creates a stable negative pressure environment. This forces moisture and volatile solvents out of the internal pore structure more effectively than heat alone.

Preventing "Popcorn" Failure

The primary danger in hard carbon preparation occurs during the subsequent carbonization phase, where temperatures rise significantly.

If moisture remains in the pores during this high-heat phase, it creates rapid dehydration. This can cause the material to expand violently—similar to popcorn popping—leading to structural collapse or the formation of bubble defects.

Vacuum drying effectively pre-empts this issue, ensuring the precursor is chemically and physically stable before entering the furnace.

Why Vacuum is Superior to Standard Heating

Lowering the Boiling Point

By reducing the environmental pressure, the vacuum oven lowers the boiling point of solvents and water.

This allows for rapid, thorough drying without requiring excessive temperatures that might degrade the precursor material prematurely.

Elimination of Oxygen

A critical advantage of the vacuum environment is the exclusion of oxygen during the heating process.

This prevents thermal oxidation of the active functional groups within the biomass. Maintaining an oxygen-free environment is essential for preserving the chemical integrity of the material surface.

Ensuring Physical Consistency

The vacuum process helps maintain the precursor in a loose, dry physical state.

It prevents the agglomeration (clumping) of particles that can occur when solvents are not removed uniformly, ensuring the raw material is consistent and dispersible.

Understanding the Trade-offs

While vacuum drying is technically superior for quality, it introduces specific operational constraints compared to standard blast drying.

Batch Processing Limitations

Vacuum drying is typically a batch process, which can be slower than continuous conveyor-belt drying methods. This can create a bottleneck in high-throughput manufacturing environments.

Equipment Complexity

Vacuum ovens require precise seals and pump maintenance. If the vacuum seal is compromised, the environment may allow oxygen ingress, negating the anti-oxidation benefits and potentially ruining the batch.

Making the Right Choice for Your Goal

To maximize the quality of your hard carbon precursors, align your drying strategy with your specific material requirements:

- If your primary focus is Structural Integrity: Prioritize the vacuum step to eliminate trapped moisture, as this is the only way to prevent bubble defects during carbonization.

- If your primary focus is Surface Chemistry: Ensure your vacuum system is perfectly sealed to exclude oxygen, preventing the unwanted oxidation of active functional groups.

In summary, the high-temperature vacuum drying oven is not just a drying tool; it is a defect-prevention device that secures the structural architecture of your final carbon material.

Summary Table:

| Feature | Vacuum Drying Oven | Standard Blast Drying |

|---|---|---|

| Moisture Removal | Deep-seated pore evacuation | Surface-level moisture removal |

| Structural Risk | Prevents "popcorn" expansion/collapse | High risk of bubble defects |

| Oxidation Control | Oxygen-free environment (Preserves groups) | High risk of thermal oxidation |

| Boiling Point | Lowered (Protects heat-sensitive materials) | Normal (Requires higher heat) |

| Material State | Loose, uniform, non-clumped | Potential for agglomeration |

Ensure the structural integrity of your hard carbon materials with KINTEK's precision thermal solutions. Backed by expert R&D and manufacturing, we provide high-performance vacuum systems and customizable lab high-temp furnaces (Muffle, Tube, Rotary, CVD) designed to meet the rigorous demands of advanced material research. Don't let moisture compromise your results—contact KINTEK today for a customized solution!

Visual Guide

References

- Liying Liu, Yang Xu. Hard carbon derived from <i>Physalis alkekengi</i> L. husks as a stable anode for sodium-ion batteries. DOI: 10.1039/d4me00007b

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- Why is vacuum sublimation preferred over recrystallization for MTO? Achieve High-Purity Methyltrioxorhenium

- Why is a vacuum oven necessary for drying ZnO-Co3O4 electrode slurries? Preserve Material Integrity at 60°C

- What materials are used in a vacuum furnace? Key Components for Extreme Heat & Purity

- What role does an LTGN vacuum furnace play in stainless steel modification? Master S-Phase Surface Hardening

- Why is a vacuum drying oven required for preparing CuCo2O4 electrodes? Ensure High-Performance Supercapacitor Testing

- What is the necessity of using a vacuum drying oven before LPBF? Ensure Purity & Density in Metal 3D Printing

- How do laboratory high-temperature furnaces achieve microstructure control in Ti-Nb-Zr alloys? Key Precision Techniques

- What is the purpose of utilizing a high vacuum system and vacuum sealing? Ensure Purity in Alloy Synthesis