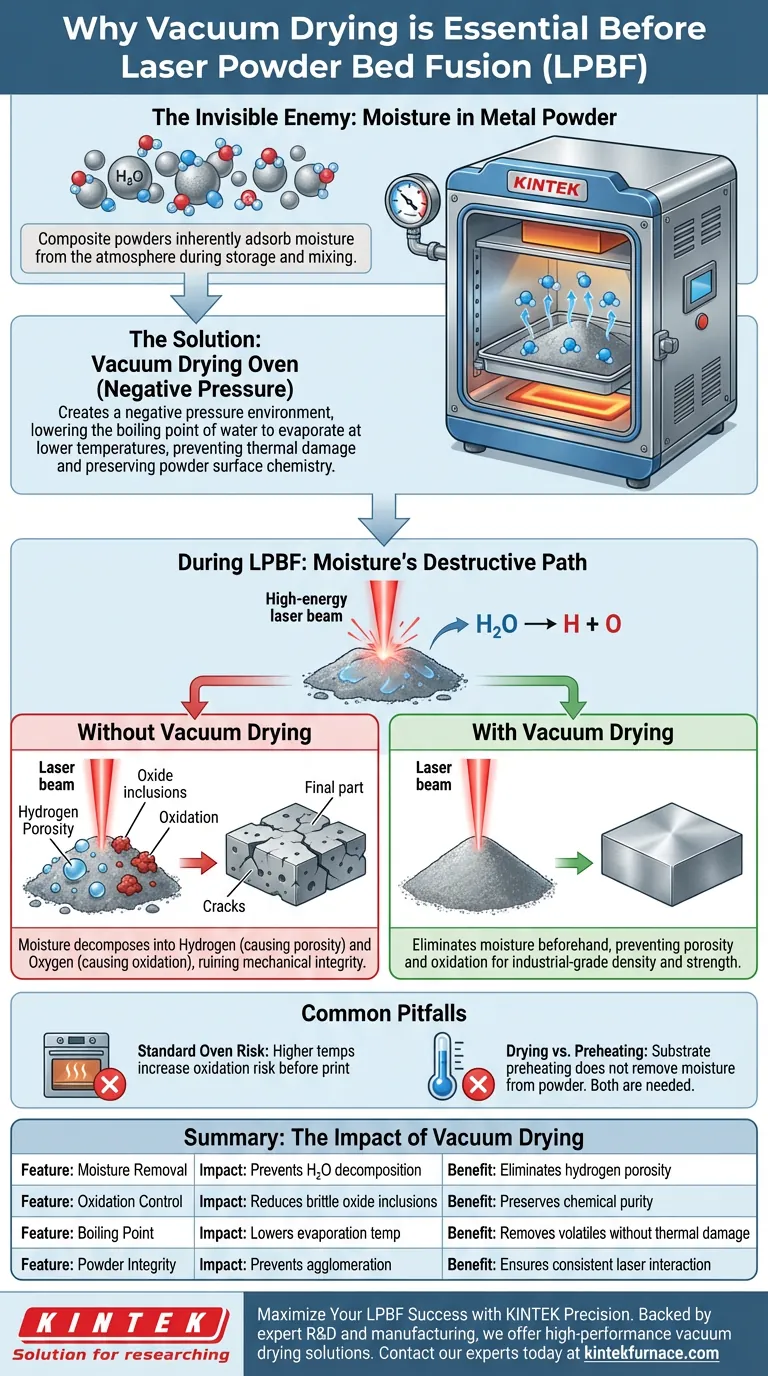

The necessity of using a vacuum drying oven before Laser Powder Bed Fusion (LPBF) lies in ensuring the chemical purity and structural density of the final part. Composite powders inherently adsorb trace amounts of moisture from the atmosphere during storage and mixing. By subjecting these powders to heat within a negative pressure environment, you remove this moisture effectively, preventing critical defects during the melting process.

Core Takeaway: Moisture is the invisible enemy of metal additive manufacturing. Vacuum drying eliminates water from powder surfaces before the laser strikes. This prevents the water from decomposing into oxygen and hydrogen during the melt, directly stopping the formation of porosity and oxidation that would otherwise ruin the mechanical integrity of the printed part.

The Physics of Moisture Removal

Eliminating Adsorbed Water

Metal and composite powders act like sponges on a microscopic level. During storage or mixing, they naturally adsorb moisture from the surrounding air. This water adheres to the surface of the powder particles and is difficult to remove through standard air drying alone.

The Vacuum Mechanism

A vacuum oven creates a negative pressure environment. This lowers the boiling point of water and other volatiles, allowing them to evaporate at significantly lower temperatures.

Preventing Thermal Damage

Because moisture can be removed at lower temperatures under vacuum, the powder is not exposed to excessive heat before printing. This preserves the surface chemistry of the powder, preventing premature oxidation or agglomeration that might occur if you attempted to "bake" the moisture out in a standard high-temperature oven.

Why Moisture Ruins LPBF Prints

The Decomposition Reaction

When the high-energy laser interacts with wet powder, the adsorbed water does not simply evaporate; it instantly decomposes. The intense heat splits the water molecules ($H_2O$) into their constituent elements: Hydrogen and Oxygen.

The Formation of Hydrogen Pores

The liberated hydrogen gas creates gas pockets within the molten pool. As the metal rapidly solidifies, this gas gets trapped, leading to hydrogen porosity. These microscopic voids significantly reduce the density of the part and act as crack initiation sites, weakening the component.

Oxidation and Structural Integrity

The oxygen released during decomposition reacts with the metal to form oxides. These oxide inclusions disrupt the material structure and reduce the inter-layer bonding strength. By removing the water beforehand, you ensure the laser interacts only with the intended alloy, preserving the structural integrity of the print.

Common Pitfalls and Considerations

Drying vs. Preheating

It is crucial to distinguish between vacuum drying the powder and preheating the substrate. While substrate preheating (e.g., to 200°C) reduces residual stress and thermal cracking, it does not solve the chemical issue of moisture in the powder. You must perform both steps to ensure a defect-free build.

The Risk of Standard Ovens

Using a standard air oven instead of a vacuum oven can be detrimental. Without the negative pressure, you must use higher temperatures to drive off moisture, which increases the risk of oxidizing the powder surface before the print even begins.

Making the Right Choice for Your Goal

If your primary focus is Structural Durability:

- Vacuum drying is mandatory to eliminate hydrogen porosity and ensure the part achieves near-100% density.

If your primary focus is Material Purity:

- Use vacuum drying to prevent oxide formation during the melt, ensuring the chemical composition of the alloy remains unaltered.

If your primary focus is Process Stability:

- Vacuum drying ensures consistent powder flow and laser interaction, reducing the variables that lead to failed prints.

Vacuum drying is not an optional step for high-performance parts; it is the baseline requirement for achieving industrial-grade density and strength.

Summary Table:

| Feature | Impact on LPBF Process | Benefit of Vacuum Drying |

|---|---|---|

| Moisture Removal | Prevents $H_2O$ decomposition into H and O | Eliminates hydrogen porosity and gas voids |

| Oxidation Control | Reduces formation of brittle oxide inclusions | Preserves chemical purity and interlayer bonding |

| Boiling Point | Lowers evaporation temp under negative pressure | Removes volatiles without thermal damage to powder |

| Powder Integrity | Prevents agglomeration and flow issues | Ensures consistent laser interaction and layer spread |

Maximize Your LPBF Success with KINTEK Precision

Don't let invisible moisture compromise the integrity of your additive manufacturing. Backed by expert R&D and manufacturing, KINTEK offers high-performance vacuum drying solutions, muffle furnaces, and CVD systems tailored for the rigorous demands of metal 3D printing. Whether you need to ensure structural durability or material purity, our customizable lab equipment provides the reliability your research demands.

Ready to eliminate porosity and oxidation in your prints? Contact our experts today to find the perfect vacuum drying system for your workflow.

Visual Guide

References

- Zhiheng Shu, Yunzhong Liu. Microstructure and Mechanical Properties of a Novel Al-Mg-Sc-Ti Alloy Fabricated by Laser Powder Bed Fusion. DOI: 10.3390/ma17030686

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What gas is used in graphite furnace? Argon vs. Nitrogen for Optimal GF-AAS Performance

- Why is a high-precision vacuum heat treatment furnace necessary for GCr15 specimens? Ensure Reliable Data Accuracy

- What factors are crucial for successful vacuum brazing? Master Cleanliness, Joint Design, and Thermal Control

- What is a crucible furnace and what is it used for? A Guide to Clean Metal Melting

- What role do vacuum systems play in chemical processes? Master Precision Control for Gas-Sensitive Reactions

- Why is a vacuum furnace preferred for jewelry melting? Achieve Purity and Precision in Your Craft

- What is the purpose of using a vacuum oven for drying coated electrode sheets in sodium-ion battery production?

- What is the purpose of using a high-vacuum system and annealing furnace for Mn–Ni–Fe–Si alloys? Unlock Data Accuracy