For jewelry manufacturing, a vacuum furnace is the preferred choice because it provides an exceptionally clean and controlled environment for melting precious metals. This process eliminates atmospheric contamination, primarily from oxygen, which is the root cause of many defects that compromise the quality, appearance, and structural integrity of the final piece.

The core challenge in melting precious metals is protecting their inherent purity from the corrupting influence of the open air. A vacuum furnace solves this by removing the atmosphere entirely, ensuring that the metal's quality and the artist's design are perfectly preserved from crucible to final form.

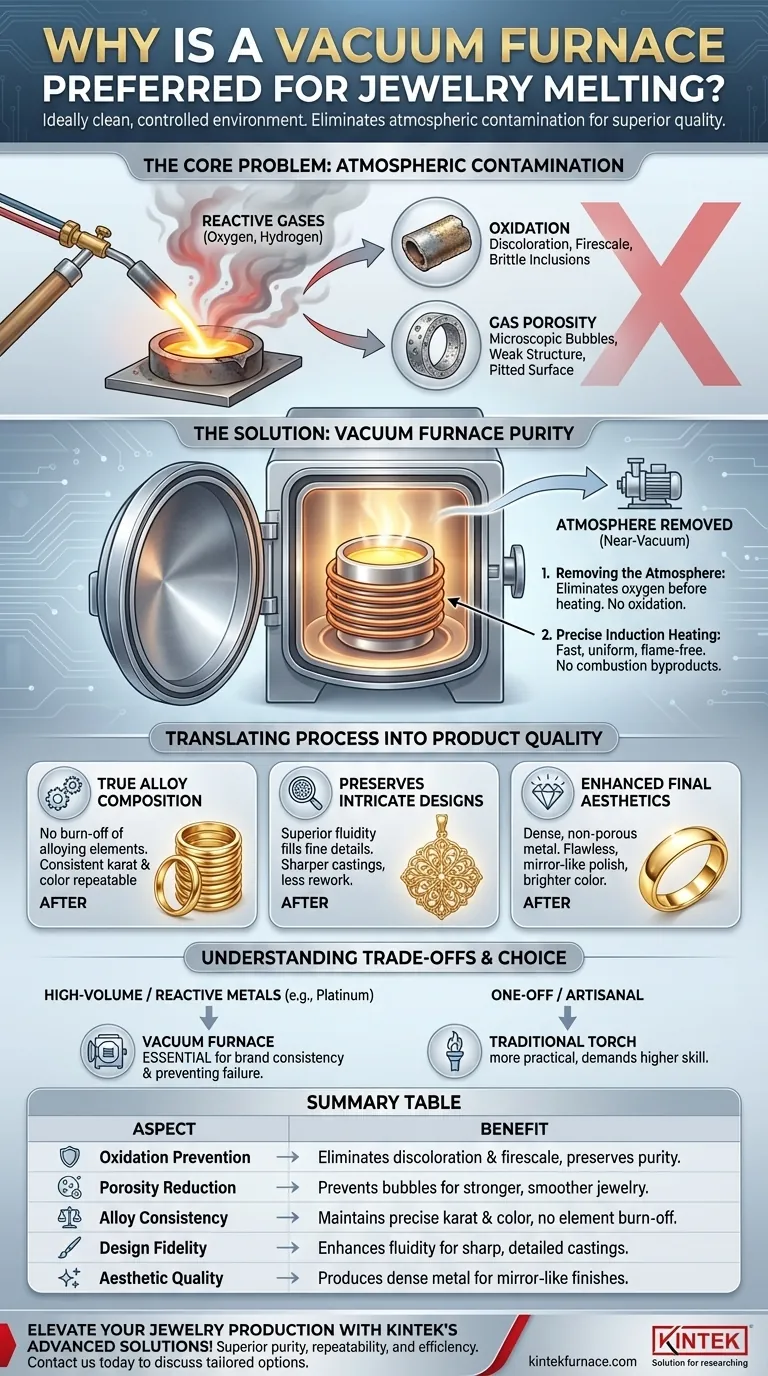

The Core Problem: Atmospheric Contamination

Before understanding the solution, it's critical to grasp the problem. Melting metal with a traditional torch or in an open-air furnace exposes the molten material to reactive gases in the atmosphere, chiefly oxygen and hydrogen.

What is Oxidation?

When molten, precious metals and their alloys are highly reactive. Oxygen in the air aggressively bonds with the metal, especially common alloying elements like copper, creating oxides.

These oxides present as discoloration, firescale, or brittle inclusions within the metal, diminishing its value and workability.

The Impact of Gas Porosity

Gases can also dissolve into the molten metal and then become trapped as the metal cools and solidifies. This creates microscopic bubbles, a defect known as gas porosity.

Porosity weakens the jewelry, making it prone to cracking. It also creates a pitted, imperfect surface that is impossible to polish to a high shine, directly impacting the final aesthetic.

How a Vacuum Furnace Delivers Purity

A vacuum furnace is an integrated system designed to counteract the problems of oxidation and porosity at a fundamental level. It combines two key technologies: a vacuum chamber and induction heating.

Principle 1: Removing the Atmosphere

The furnace features an airtight chamber, typically made of stainless steel, from which a vacuum pump removes the air. This creates a near-vacuum environment.

By eliminating the oxygen before the metal is heated, the possibility of oxidation is completely removed. This is far more effective than using flux or deoxidizing agents, which only treat the symptoms of contamination.

Principle 2: Clean and Precise Induction Heating

Instead of an external flame, a vacuum furnace uses induction heating. An electric coil generates a powerful magnetic field that heats the metal crucible directly from within.

This method is incredibly fast, uniform, and precise. It allows for exact temperature control, preventing the overheating that can degrade alloys. Since there is no flame, no combustion byproducts are introduced into the melt.

Translating Process into Product Quality

The pristine environment of a vacuum furnace has direct, measurable impacts on the quality of the finished jewelry.

Ensuring True Alloy Composition

Many precious metals are alloys, such as 14k or 18k gold. The color and material properties depend on a precise ratio of metals.

In a vacuum, there is no "burn-off" of sensitive alloying elements due to oxidation. This ensures the intended karat, color, and hardness are achieved with perfect repeatability from batch to batch.

Preserving Intricate Designs

Clean, gas-free molten metal has superior fluidity. It flows more smoothly and evenly into the fine details of a mold.

This results in sharper, more complete castings of intricate patterns, filigree, and settings, preserving the integrity of the original design without the need for extensive and risky rework.

Enhancing Final Aesthetics

The metal that emerges from a vacuum furnace is dense and non-porous. This is the ideal foundation for finishing.

A pure, solid casting can be polished to a flawless, mirror-like shine. The color is brighter and more consistent, and there are no surface pits to mar the final appearance.

Understanding the Trade-offs

While superior, a vacuum furnace is not the right tool for every context. Objectivity requires acknowledging its limitations.

Initial Investment and Complexity

Vacuum furnaces represent a significant capital investment compared to a simple torch or kiln setup. They are complex machines that require trained operators and consistent maintenance of the vacuum pump and seals.

Scale of Production

These systems are designed for batch production and are most efficient when melting specific quantities of metal. They are less practical for a jeweler who needs to melt a very small, single gram of metal for a quick repair or a one-off piece.

Making the Right Choice for Your Goal

Your choice of melting equipment should be dictated by your production goals, quality standards, and the materials you work with.

- If your primary focus is high-volume, repeatable quality for a fine jewelry line: A vacuum furnace is an essential investment to ensure brand consistency and minimize defects.

- If your primary focus is working with reactive metals like platinum or titanium: The controlled atmosphere of a vacuum furnace is non-negotiable to prevent catastrophic material failure.

- If your primary focus is one-off artisanal pieces or learning the craft: Traditional torch melting can be more cost-effective and practical, though it demands a higher level of skill to manage oxidation.

By removing the fundamental risk of atmospheric contamination, the vacuum furnace empowers jewelers to achieve the purest possible expression of their materials and designs.

Summary Table:

| Aspect | Benefit |

|---|---|

| Oxidation Prevention | Eliminates oxygen to avoid discoloration and firescale, preserving metal purity. |

| Porosity Reduction | Prevents gas bubbles for stronger, smoother jewelry with better polishability. |

| Alloy Consistency | Maintains precise karat and color by preventing burn-off of alloying elements. |

| Design Fidelity | Enhances fluidity for sharp, detailed castings of intricate patterns and settings. |

| Aesthetic Quality | Produces dense, non-porous metal for mirror-like finishes and consistent appearance. |

Elevate your jewelry production with KINTEK's advanced vacuum furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we offer high-temperature furnaces like Vacuum & Atmosphere Furnaces, designed for precise, contamination-free melting of precious metals. Our strong deep customization capability ensures we meet your unique experimental and production needs, delivering superior purity, repeatability, and efficiency. Contact us today to discuss how our tailored solutions can enhance your craft and grow your business!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- How is operator safety ensured during the vacuum induction melting process? Discover Multi-Layered Protection for Your Lab

- How does vacuum induction melting work? Achieve Ultra-Pure, High-Performance Alloys

- What industries benefit from Vacuum Induction Melting Furnaces? Unlock High-Purity Metals for Aerospace, Medical, and More

- What are the key components of a Vacuum Induction Melting (VIM) furnace? Master High-Purity Metal Processing

- What are the advantages of vacuum induction melting? Achieve Superior Purity for High-Performance Alloys