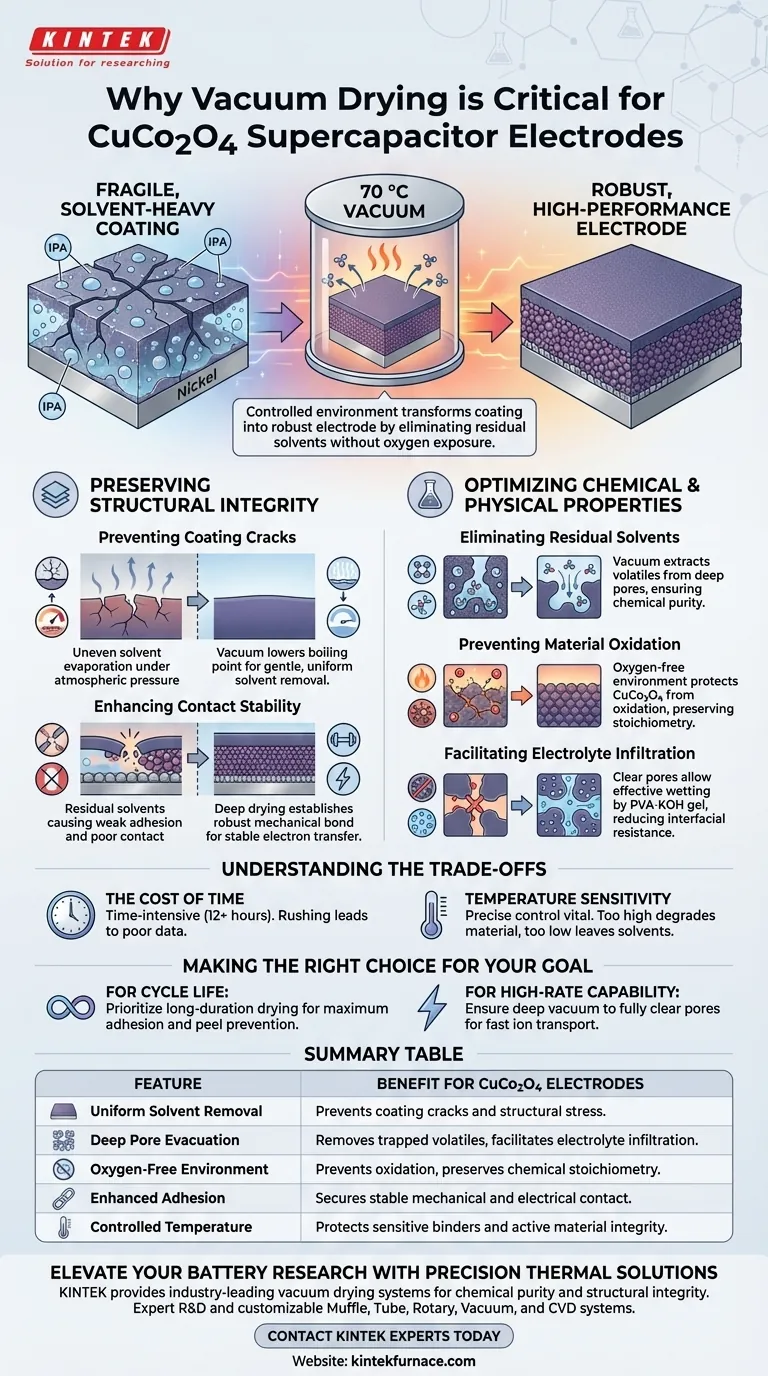

The vacuum drying oven is critical for ensuring the structural integrity and chemical purity of CuCo2O4 electrodes. It creates a controlled environment—typically around 70 °C under vacuum—to effectively eliminate residual solvents like isopropyl alcohol from the active material layer. This process is mandatory to prevent coating cracks caused by uneven evaporation and to secure a stable electrical contact between the active substance and the nickel substrate.

The vacuum drying process transforms a fragile, solvent-heavy coating into a robust, high-performance electrode. By removing trapped volatiles without exposing the material to oxygen, you ensure that the electrochemical data collected during testing reflects the material's true potential, not artifacts caused by structural defects or impurities.

Preserving Structural Integrity

Preventing Coating Cracks

When solvents evaporate under standard atmospheric pressure, the process is often uneven. This uneven evaporation creates internal stress within the active material layer.

Vacuum drying mitigates this by lowering the boiling point of solvents like isopropyl alcohol. This allows for a gentle, uniform removal of the solvent, significantly reducing the risk of cracks forming in the coating.

Enhancing Contact Stability

For a supercapacitor to function correctly, the active material (CuCo2O4) must have perfect electrical continuity with the current collector (the nickel substrate).

Residual solvents act as a barrier, weakening the physical adhesion. By performing deep drying, you ensure the active material adheres tightly to the nickel mesh, establishing the robust mechanical bond necessary for stable electron transfer.

Optimizing Chemical and Physical Properties

Eliminating Residual Solvents

Surface drying is often insufficient for porous electrode materials. Solvents and moisture can remain trapped deep within the micropores of the material.

The vacuum environment exerts a "pull" that extracts these trapped volatiles from the deepest pores. This ensures that the electrode is chemically pure and free of substances that could interfere with electrochemical reactions.

Preventing Material Oxidation

Heat is necessary to drive off solvents, but heat in the presence of air can damage sensitive materials.

Drying under vacuum removes oxygen from the chamber. This protects the CuCo2O4 from oxidation during the heating process, preserving the specific chemical stoichiometry required for optimal capacitance.

Facilitating Electrolyte Infiltration

An often-overlooked benefit of vacuum drying is the preparation of the material's pore structure.

By extracting air and solvents from micropores, the process leaves the active surface fully accessible. This allows electrolytes, such as PVA-KOH gel, to effectively wet and infiltrate the electrode arrays later in the assembly process, drastically reducing interfacial resistance.

Understanding the Trade-offs

The Cost of Time

Vacuum drying is a time-intensive process, often requiring overnight treatment or cycles lasting 12+ hours. Rushing this step to save time is a common pitfall that leads to "noisy" data and poor cycling stability.

Temperature Sensitivity

While the vacuum lowers the boiling point of solvents, accurate temperature control is still vital. Setting the temperature too high, even in a vacuum, can degrade the binder or the active material itself. Conversely, temperatures that are too low may fail to remove solvents with higher boiling points, such as NMP, if they were used in the slurry.

Making the Right Choice for Your Goal

To obtain reliable data from your CuCo2O4 supercapacitor testing, apply the drying process based on your specific performance metrics:

- If your primary focus is Cycle Life: Prioritize long-duration drying to ensure maximum adhesion prevents the active material from peeling off the substrate during repeated charging.

- If your primary focus is High-Rate Capability: Ensure deep vacuum levels to fully clear micropores, allowing maximum electrolyte penetration for faster ion transport.

By strictly adhering to a vacuum drying protocol, you eliminate variable defects, ensuring that your test results are a true measure of your material's chemistry rather than its preparation flaws.

Summary Table:

| Feature | Benefit for CuCo2O4 Electrodes |

|---|---|

| Uniform Solvent Removal | Prevents coating cracks and structural stress in active materials. |

| Deep Pore Evacuation | Removes trapped volatiles to facilitate electrolyte infiltration. |

| Oxygen-Free Environment | Prevents oxidation and preserves chemical stoichiometry. |

| Enhanced Adhesion | Secures stable mechanical and electrical contact with nickel substrates. |

| Controlled Temperature | Protects sensitive binders and active material integrity. |

Elevate Your Battery Research with Precision Thermal Solutions

Don't let preparation flaws compromise your electrochemical data. KINTEK provides industry-leading vacuum drying systems designed to deliver the chemical purity and structural integrity your CuCo2O4 electrodes demand.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet the unique requirements of your advanced material testing.

Ready to achieve superior electrode performance?

Contact KINTEK Experts Today to find the perfect high-temperature solution for your lab.

Visual Guide

References

- Johnnys da Silva Hortêncio, Fausthon Fred da Silva. Bifunctional MOF‐on‐MOF‐Derived CuCo <sub>2</sub> O <sub>4</sub> for Oxygen Evolution Reaction Electrocatalysis and Supercapacitor Electrodes. DOI: 10.1002/open.202500180

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering and Brazing Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What are the general steps for operating a vacuum furnace? Master Contaminant-Free Heat Treatment

- What are the main advantages of customized vacuum furnaces? Unlock Tailored Precision for Superior Quality

- How does the combined use of a centrifuge and a vacuum drying oven solve issues in H-Beta zeolite catalyst recovery?

- How does a vacuum furnace prevent oxidation of metals? Unlock Purity and Strength in Heat Treatment

- Why bake electrode sheets in a vacuum oven for button cells? Ensure Battery Performance and Chemical Purity

- How do continuous vacuum furnaces contribute to metal annealing and hardening? Achieve Superior Metallurgical Purity

- How do the drying conditions in a vacuum drying oven affect NiS2 electrode quality? Optimize Your Battery Performance

- How does vacuum level affect vapor pressure in materials? Lower Boiling Points for Better Processing