The primary advantage of a customized vacuum furnace is its ability to be engineered precisely for your specific process requirements, moving beyond the compromises of a standard, off-the-shelf model. This tailored approach allows for the optimization of key parameters like temperature and vacuum level, which directly translates to superior product quality, enhanced operational efficiency, and a safer working environment.

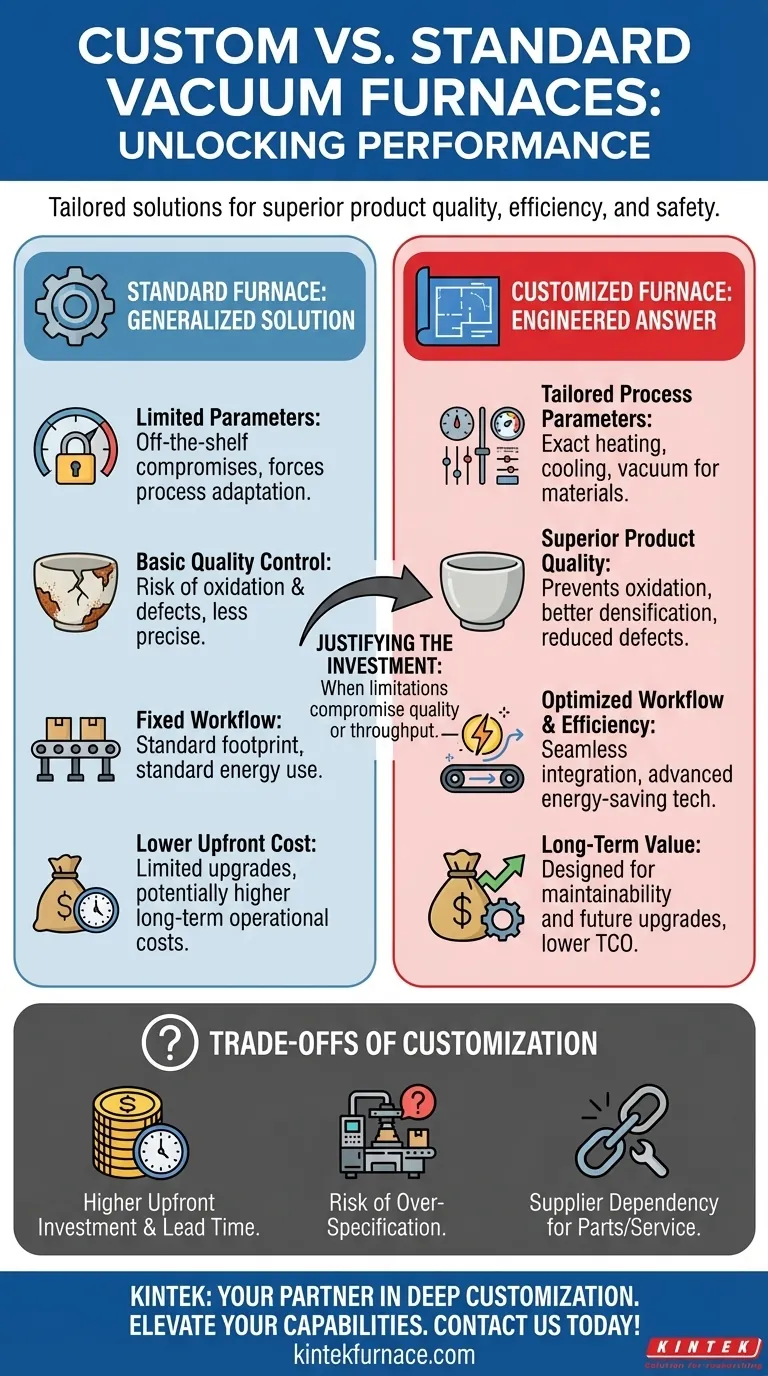

While a standard furnace provides a generalized solution, a custom furnace is an engineered answer to a specific problem. The decision to customize is justified when a standard model's limitations would compromise final product quality, production throughput, or long-term operational costs.

Beyond 'One-Size-Fits-All': The Core Benefits of Customization

The fundamental value of a custom furnace lies in its perfect alignment with a specific production goal. This alignment manifests in several key areas.

Tailored Process Parameters

A custom furnace is designed and manufactured according to your exact process needs. This includes critical parameters like maximum heating temperature, ultimate vacuum degree, and precise heating and cooling rates.

This flexibility ensures the equipment is a perfect match for your materials and desired outcomes, rather than forcing your process to adapt to the limitations of a standard furnace.

Unlocking Superior Product Quality

This level of control creates a more precise and stable processing environment. The vacuum atmosphere itself prevents material oxidation and maintains material purity by removing harmful components like water and nitrogen.

Furthermore, a tailored heating and cooling cycle reduces defects like deformation and cracking. For processes like sintering, it promotes material densification by allowing gases to escape, which reduces pores and improves the final product's density and performance.

Optimized for Your Production Workflow

Customization extends beyond internal specifications. The physical footprint, loading mechanisms, and control interface can all be designed to integrate seamlessly into your existing production line, optimizing workflow and throughput.

Long-Term Value and Operational Efficiency

The benefits of a custom furnace are not just limited to the initial process but extend throughout the equipment's entire lifecycle.

Enhanced Energy Efficiency

Custom furnaces often incorporate advanced heating technologies and superior insulation materials chosen specifically for your target temperature range.

This significantly reduces energy consumption and improves thermal efficiency, leading to lower production costs and a smaller environmental footprint over years of operation.

Designed for Maintainability and Upgrades

Custom equipment is typically designed with long-term service in mind. Components are chosen and placed to allow for easier maintenance access, reducing downtime.

Crucially, they can be built with future upgrades in mind, allowing you to adapt the furnace to meet new production demands without replacing the entire system.

Inherent Safety by Design

Vacuum furnaces operate at a negative pressure, which inherently eliminates the risk of an explosion that can exist with pressurized systems.

The low-oxygen environment also minimizes the risk of fire from the oxidation of materials at high temperatures, making them significantly safer than conventional heating furnaces.

Understanding the Trade-offs

While the advantages are significant, a custom solution is not always the right choice. An objective decision requires acknowledging the potential downsides.

The Upfront Investment

Custom-engineered equipment almost always carries a higher initial purchase price and a longer lead time compared to standard, mass-produced models. This investment must be weighed against the expected gains in quality and efficiency.

The Risk of Over-Specification

It is possible to design a furnace that is far more complex or capable than your process truly requires. This over-specification adds unnecessary cost and potential maintenance complexity without providing a tangible return.

Supplier Dependency

Service, support, and spare parts for a custom furnace are typically tied to the original manufacturer. This can create a dependency that doesn't exist with standard models where parts may be more interchangeable.

Making the Right Choice: Standard vs. Custom

Your decision should be guided by a clear analysis of your process requirements, budget, and long-term strategic goals.

- If your primary focus is cost-effectiveness for a standard application: A standard, off-the-shelf furnace is likely the most practical and efficient choice for well-established processes.

- If your primary focus is maximum material purity and performance: A custom furnace designed for your specific material and vacuum level is essential to prevent oxidation and ensure superior densification.

- If your primary focus is experimental research or a unique geometry: A custom-built furnace is often the only way to meet atypical requirements for temperature, pressure, or part handling.

- If your primary focus is long-term operational efficiency: A custom furnace optimized for your specific energy use and designed for future upgrades can offer a lower total cost of ownership despite a higher initial price.

Ultimately, the right decision hinges on a clear understanding of your process demands and strategic goals.

Summary Table:

| Aspect | Standard Furnace | Customized Furnace |

|---|---|---|

| Process Fit | Generalized, may require compromises | Tailored to exact specifications |

| Product Quality | Basic control, risk of oxidation | Superior purity, reduced defects, better densification |

| Operational Efficiency | Fixed workflow, standard energy use | Optimized integration, higher energy efficiency |

| Long-Term Value | Lower upfront cost, limited upgrades | Higher initial investment, designed for maintainability and upgrades |

| Safety | Standard safety features | Enhanced safety with negative pressure and low-oxygen environment |

Ready to elevate your laboratory's capabilities? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental requirements. Whether you need tailored process parameters, superior product quality, or long-term operational efficiency, we're here to help. Contact us today to discuss how our customized vacuum furnaces can optimize your production workflow and deliver unmatched value!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Induction Melting Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What are the applications of hot pressing? Achieve Maximum Material Performance

- What are the advantages of using vacuum hot press furnaces over traditional furnaces? Achieve Superior Material Quality and Performance

- What is the process of vacuum hot pressing? Achieve Ultra-Dense, High-Purity Materials

- How should heating elements and pressurization methods be selected for vacuum hot press furnaces? Optimize for Temperature and Density

- What is vacuum hot pressing? Achieve Superior Material Strength and Purity