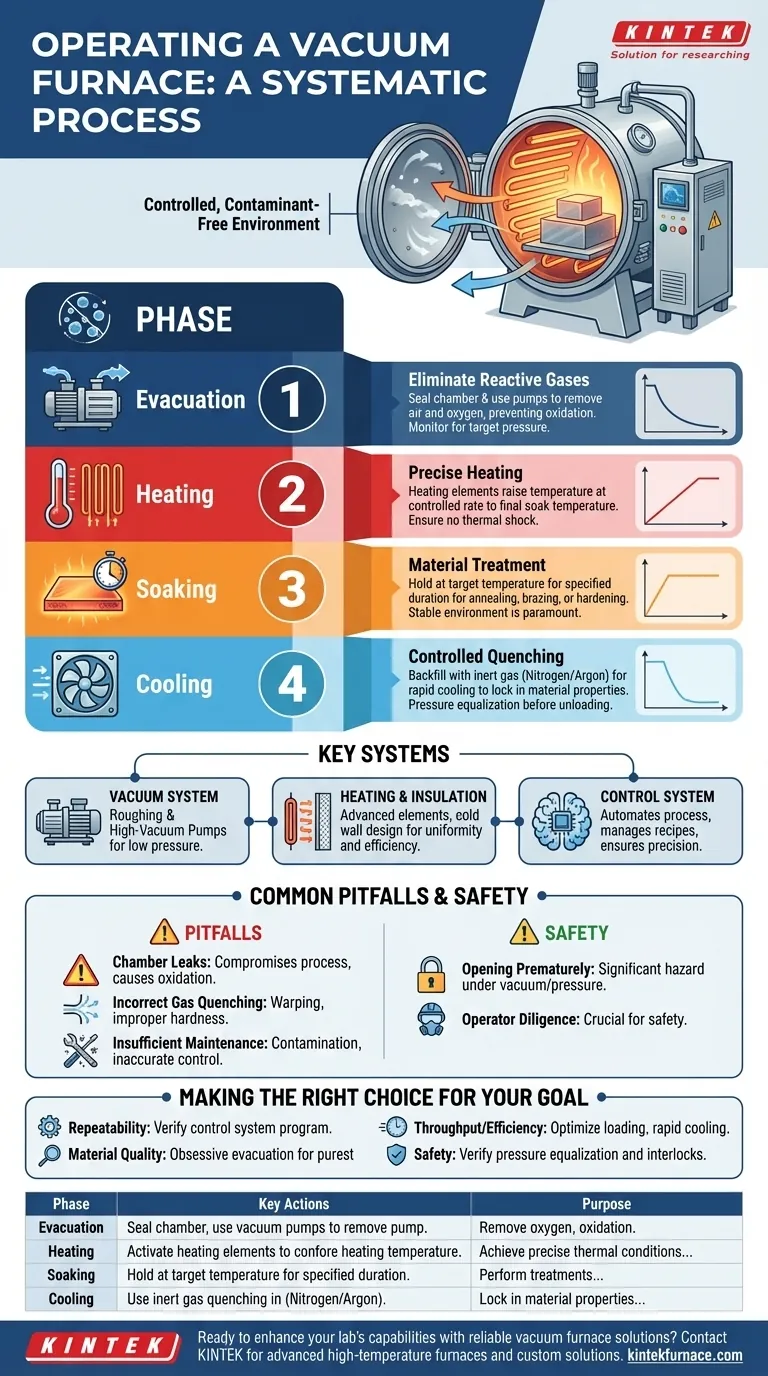

Operating a vacuum furnace is a systematic process centered on creating a controlled, contaminant-free environment before applying heat. The general steps involve loading the material, sealing the furnace, using a pump system to create a deep vacuum, executing a precise heating and cooling cycle as required by the material's process, and safely returning the chamber to atmospheric pressure before unloading.

A vacuum furnace is not simply an oven; it is a sophisticated environmental control system. Understanding its operation is about mastering the methodical removal of atmospheric contaminants before applying heat to ensure the absolute integrity and desired properties of the material being processed.

The Core Principles of Vacuum Furnace Operation

A successful furnace cycle is less a checklist and more an execution of four distinct phases. Each phase serves a critical purpose in achieving the final desired outcome for the material.

Phase 1: Evacuation

The primary purpose of a vacuum furnace is to eliminate the reactive gases—primarily oxygen—found in normal atmosphere. This prevents oxidation and other contamination at elevated temperatures.

This is achieved by sealing the furnace chamber and using a vacuum pump system to remove the air. The process typically requires monitoring vacuum levels to ensure the target pressure has been reached before any heating begins.

Phase 2: Heating

Once the target vacuum is achieved, the heating cycle begins. Heating elements, managed by a precise temperature control system, raise the temperature of the chamber and the material inside.

The control system dictates the rate of temperature rise and the final "soak" temperature. This precision is critical for ensuring the material undergoes the correct metallurgical or chemical changes without thermal shock or deviation.

Phase 3: Soaking (Treatment)

During the soak, the furnace holds the material at the target temperature for a specified duration. This is the stage where the actual treatment—such as annealing, brazing, or hardening—takes place.

The stability of both the vacuum level and the temperature during this phase is paramount for achieving consistent, repeatable results across the entire workload.

Phase 4: Cooling (Quenching)

After the treatment is complete, the material must be cooled in a controlled manner. Modern furnaces often use rapid cooling, or quenching, by backfilling the chamber with an inert gas like nitrogen or argon and circulating it at high velocity.

This rapid cooling "locks in" the material properties achieved during the heating phase. The cycle ends with pressure equalization, where the chamber is slowly returned to atmospheric pressure, allowing the door to be opened safely for unloading.

Understanding the Key Systems

A vacuum furnace is an integration of several critical systems working in concert. Familiarity with these systems is key to effective operation.

The Vacuum System

This is the heart of the furnace. It typically consists of a mechanical "roughing" pump that removes the bulk of the air, followed by a high-vacuum pump (like a diffusion or turbomolecular pump) to achieve the very low pressures needed for high-purity processing.

The Heating and Insulation System

Modern furnaces use advanced heating elements for uniform temperature and cold wall design, where the furnace body is water-cooled. This, combined with high-tech insulation, allows for rapid temperature changes and minimizes energy loss, making the process highly efficient.

The Control System

This is the brain of the operation. The control system automates the entire process, managing pump sequencing, valve operation, heating rates, soak times, and cooling cycles. It ensures that the prescribed "recipe" for a given material is followed exactly every time.

Common Pitfalls and Safety Considerations

While highly automated, vacuum furnaces require diligence to operate correctly and safely. Awareness of potential issues is crucial for preventing failed cycles and ensuring operator safety.

Ignoring Chamber Leaks

Even a small leak in a door seal or fitting can compromise the entire process by allowing oxygen to enter the chamber at high temperatures, leading to oxidized and scrapped parts. Regular leak checks are essential maintenance.

Incorrect Gas Quenching

Cooling too slowly or with uneven gas flow can result in parts that do not meet hardness specifications or that have warped due to thermal stress. The cooling profile is just as critical as the heating profile.

Attempting to Open the Door Prematurely

Never attempt to open the furnace door until the chamber pressure has been fully equalized to the surrounding atmosphere. Opening the door under vacuum or pressure presents a significant safety hazard. Modern furnaces have safety interlocks to prevent this.

Insufficient Maintenance

A vacuum furnace is a precision instrument. Oil from pumps can contaminate the chamber, and buildup on heating elements or thermocouples can lead to inaccurate temperature control. Following the manufacturer's maintenance schedule is non-negotiable for reliable operation.

Making the Right Choice for Your Goal

Your operational focus will shift slightly depending on your primary objective.

- If your primary focus is process repeatability: Concentrate on ensuring the vacuum level and temperature profile are identical for every run by verifying the control system's program.

- If your primary focus is throughput and efficiency: Optimize your loading configuration and leverage rapid cooling features to shorten cycle times as much as the process allows.

- If your primary focus is material quality: Pay obsessive attention to the initial evacuation phase to achieve the deepest vacuum possible, ensuring the purest environment for your material.

- If your primary focus is safety: Always verify that pressure equalization is complete and that all system interlocks are functional before interacting with the furnace chamber.

By mastering these fundamental principles, you become more than an operator; you become a process owner capable of delivering predictable, high-quality results.

Summary Table:

| Phase | Key Actions | Purpose |

|---|---|---|

| Evacuation | Seal chamber, use vacuum pumps, monitor pressure | Remove oxygen and contaminants to prevent oxidation |

| Heating | Activate heating elements, control temperature rise | Achieve precise thermal conditions for material changes |

| Soaking | Hold at target temperature for set duration | Perform treatments like annealing or brazing |

| Cooling | Use inert gas quenching, equalize pressure | Lock in material properties and ensure safe unloading |

Ready to enhance your lab's capabilities with reliable vacuum furnace solutions? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnaces, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization ensures they meet your unique experimental needs for precise, contamination-free processing. Contact us today to discuss how we can support your goals!

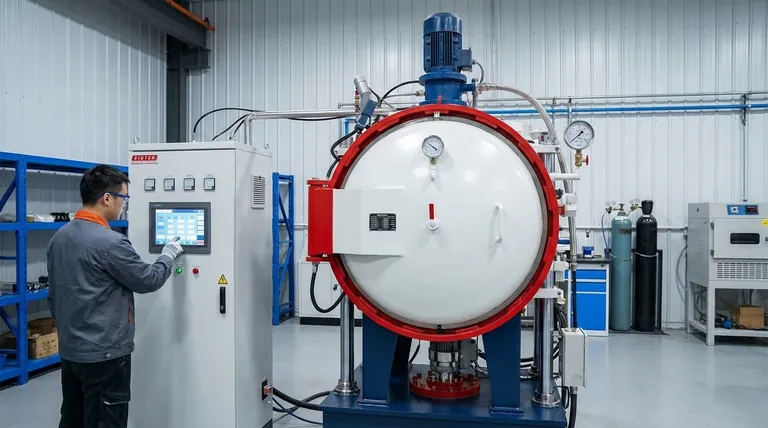

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- Why is a vacuum hot press sintering furnace required for nanocrystalline ceramics? Preserve Structure with Pressure

- What is the mechanism of a vacuum sintering furnace for AlCoCrFeNi2.1 + Y2O3? Optimize Your High-Entropy Alloy Processing

- How do vacuum sintering and annealing furnaces contribute to the densification of NdFeB magnets?

- What role does a vacuum hot pressing furnace play in TiBw/TA15 synthesis? Enhance In-Situ Composite Performance

- Why is a vacuum environment essential for sintering Titanium? Ensure High Purity and Eliminate Brittleness