The air circulation furnace serves as the critical gatekeeper of structural integrity during the initial debinding stage of porous Hastelloy-X production. Its primary role is to execute a "gentle debinding" process, utilizing an extremely slow heating rate—typically 0.2 °C per minute up to 210 °C—to remove paraffin binders and carbamide space holders. This controlled low-temperature environment ensures that gaseous decomposition products escape gradually, preventing the internal pressures that would otherwise cause the delicate porous skeleton to crack or collapse.

The air circulation furnace facilitates the transition from a composite "green" state to a stable porous preform by managing the slow, evaporated removal of organic additives. Its role is focused entirely on structural preservation through thermal precision, ensuring the integrity of the part before high-temperature sintering begins.

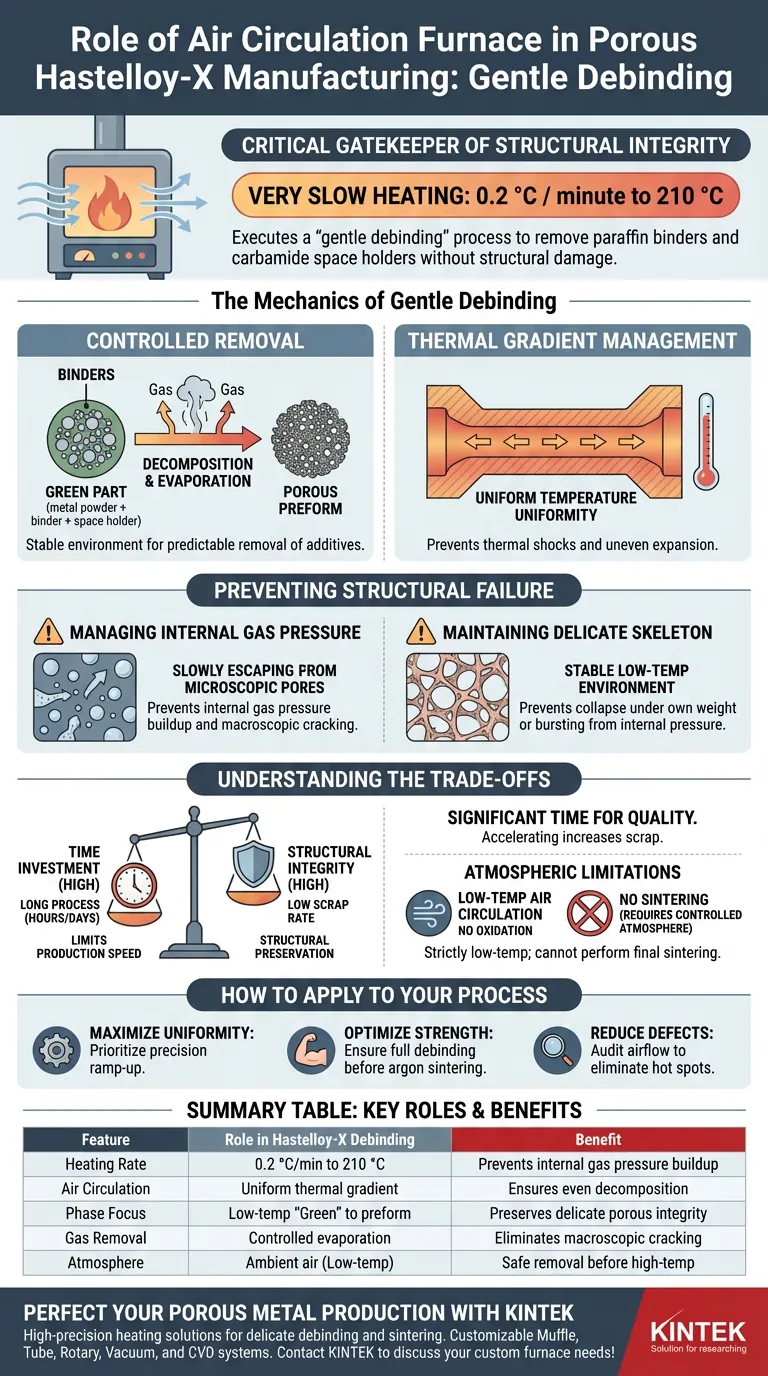

The Mechanics of Gentle Debinding

Controlled Removal of Additives

In the initial phase, the furnace must remove the paraffin binder and carbamide space holder particles that define the future pores. The air circulation furnace provides a stable environment where these materials can decompose or evaporate at a predictable rate. This step is essential because these materials occupy the space that will eventually become the functional porosity of the Hastelloy-X.

Thermal Gradient Management

By maintaining a remarkably slow heating rate of 0.2 °C per minute, the furnace prevents thermal shocks and uneven expansion. This precision ensures that the temperature remains uniform throughout the entire cross-section of the component. A uniform temperature profile is vital for ensuring that the organic components exit the structure at the same rate from the core to the surface.

Preventing Structural Failure

Managing Internal Gas Pressure

As binders and space holders decompose, they transform into gaseous products that must migrate out of the metal matrix. If the heating rate is too aggressive, these gases build up pressure faster than they can escape through the microscopic pathways. The air circulation furnace mitigates this risk, preventing the internal stresses that lead to macroscopic cracking.

Maintaining the Delicate Porous Skeleton

Before the metal particles are fused together, the "green" part is held together only by the remaining binder and mechanical interlocking. The furnace provides the stable low-temperature environment required to maintain this fragile state. By avoiding rapid gas release, the furnace ensures the delicate porous structure does not collapse under its own weight or burst from internal pressure.

Understanding the Trade-offs

Throughput vs. Structural Integrity

The primary trade-off of using an air circulation furnace for gentle debinding is the significant time investment required. A heating rate of 0.2 °C per minute means the initial phase can take several hours or even days to reach the target 210 °C. While this limits production speed, any attempt to accelerate this phase drastically increases the scrap rate due to structural defects.

Atmospheric Limitations

Because this furnace operates with air circulation, it is strictly limited to low-temperature phases where oxidation of the Hastelloy-X is negligible. It cannot perform the final sintering required for mechanical strength, which requires a controlled atmosphere (such as high-purity argon) and much higher temperatures. Relying on an air furnace for too long or at too high a temperature could lead to unwanted oxide formation on the metal particle surfaces.

How to Apply This to Your Manufacturing Process

The role of the air circulation furnace is specialized and cannot be bypassed if the goal is a high-quality porous metal.

- If your primary focus is maximizing structural uniformity: Prioritize the precision of the air circulation furnace's ramp-up cycle to ensure every part of the geometry degasses at the same rate.

- If your primary focus is optimizing mechanical strength: Ensure the debinding phase in the air furnace is fully completed before moving to an argon-shielded sintering furnace to promote the formation of clean sintering necks.

- If your primary focus is reducing manufacturing defects: Audit the airflow patterns within the furnace to ensure there are no "hot spots" that could cause localized rapid gas expansion and subsequent cracking.

By mastering the slow, deliberate transition provided by the air circulation furnace, you secure the fundamental architecture of the porous Hastelloy-X before it is finalized in the sintering forge.

Summary Table:

| Feature | Role in Hastelloy-X Debinding | Benefit |

|---|---|---|

| Heating Rate | 0.2 °C per minute up to 210 °C | Prevents internal gas pressure buildup |

| Air Circulation | Uniform thermal gradient management | Ensures even decomposition of organic binders |

| Phase Focus | Low-temperature "Green" state to preform | Preserves delicate porous skeleton integrity |

| Gas Removal | Controlled evaporation of paraffin/carbamide | Eliminates macroscopic cracking and collapse |

| Atmosphere | Ambient air (Low-temp only) | Safe removal of additives before high-temp sintering |

Perfect Your Porous Metal Production with KINTEK

Don't let structural defects compromise your advanced material manufacturing. KINTEK provides high-precision heating solutions designed specifically for the delicate debinding and sintering phases of specialty alloys like Hastelloy-X.

Backed by expert R&D and world-class manufacturing, we offer customizable Muffle, Tube, Rotary, Vacuum, and CVD systems tailored to your unique laboratory or production needs. Whether you require the ultra-slow ramp rates of an air circulation furnace or the high-purity argon environments of a vacuum sintering furnace, our engineers are ready to help you optimize your process.

Enhance your material integrity today—contact KINTEK to discuss your custom furnace needs!

Visual Guide

References

- Aleksandra Bętkowska, Wojciech Polkowski. Microstructure and mechanical properties of highly porous Hastelloy-X nickel superalloy produced by a space holder approach. DOI: 10.1038/s41598-024-84321-3

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1200℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the relationship between temperature and the furnace atmosphere in material processing? Master the Critical Heat-Environment Balance

- How is the sealing performance of an experimental box type atmosphere furnace enhanced? Boost Purity with Advanced Sealing Systems

- What are the two main purposes of controlling the atmosphere in a lab furnace? Master Material Protection and Transformation

- Why is a melting furnace with a constant argon flow required? Ensure Purity in Iodine-Bearing Glass Production

- How do atmosphere control systems contribute to furnace operation? Unlock Precision and Quality in Material Processing

- What is a box type annealing atmosphere furnace? Master Controlled Heat Treatment for Superior Materials

- How does the heating mechanism differ between a muffle furnace and an atmosphere furnace? Discover Key Design and Application Insights

- What factors need adjusting in an atmosphere protection muffle furnace? Optimize for Process Control and Safety