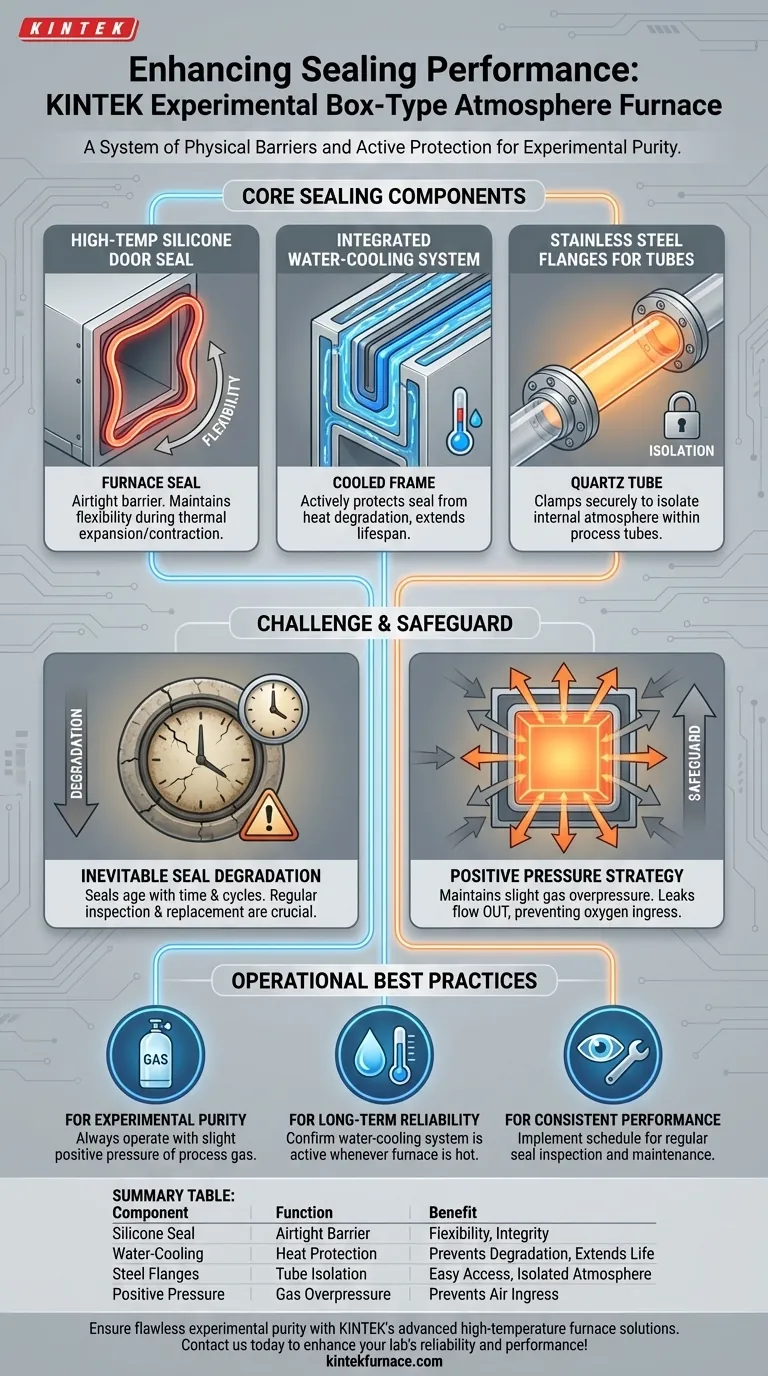

To enhance sealing performance, an experimental box-type atmosphere furnace integrates a system of physical barriers and active protection. This is primarily achieved using high-temperature silicone rubber seals on the furnace door, often combined with a water-cooling system, and specialized stainless steel flanges to seal any process tubes. These components work in unison to create an airtight environment, isolating the internal atmosphere from outside air and preventing contamination.

The central challenge in furnace sealing is not merely creating a barrier, but maintaining its integrity under extreme temperatures. Therefore, superior sealing performance depends on a system that both physically blocks gas exchange and actively protects the sealing materials from heat degradation.

The Core Components of an Airtight Seal

The effectiveness of an atmosphere furnace is directly tied to its ability to maintain a pure, controlled environment. This is accomplished through several key engineering features designed specifically for high-temperature sealing.

The Furnace Door Seal

The primary barrier against the external environment is the seal on the furnace door. This is typically made from a high-temperature silicone rubber gasket.

This material is chosen for its ability to remain flexible and create a tight seal even as the furnace structure expands and contracts with temperature changes.

The Water-Cooling System

A silicone seal alone would quickly fail when exposed to the high temperatures radiating from the furnace chamber. A water-cooling system is therefore integrated into the furnace door or frame.

This system circulates cool water through channels adjacent to the seal. By actively removing heat, the cooling system keeps the silicone rubber within its operational temperature range, preventing it from becoming brittle, melting, or losing its sealing properties.

Sealing Flanges for Process Tubes

For experiments where materials are placed inside a quartz or corundum tube that runs through the furnace, a different sealing method is required.

Stainless steel flanges are used at both ends of the tube. These flanges clamp down securely, creating an airtight seal that isolates the atmosphere inside the tube. This allows for easy insertion and removal of samples while ensuring the integrity of the controlled environment.

Understanding the Trade-offs and Failure Points

Achieving a perfect seal is a constant engineering challenge. Understanding the limitations is critical for successful operation and troubleshooting.

Inevitable Seal Degradation

Even with active cooling, all sealing materials have a finite lifespan. Over time and through repeated heating and cooling cycles, silicone gaskets will slowly harden, crack, or compress permanently.

This degradation is a primary cause of atmosphere contamination. Regular inspection and scheduled replacement of seals are essential maintenance tasks for ensuring experimental purity.

Positive Pressure as a Safeguard

No seal is perfect forever. A common and highly effective operational strategy is to maintain a slight positive pressure of the desired gas (like argon or nitrogen) inside the furnace.

If a microscopic leak develops, this positive pressure ensures that the pure internal gas leaks out rather than ambient air leaking in. This simple technique provides a robust defense against oxygen contamination, which can ruin sensitive experiments.

The Impact of User Operation

The longevity of the seals is also dependent on proper use. Forcing a furnace door shut or over-tightening the bolts on a sealing flange can physically damage the gasket, creating an immediate leak path.

Proper training and careful operation are crucial to prevent premature failure of the sealing system.

Making the Right Choice for Your Goal

To ensure the integrity of your work, your operational focus must align with the mechanics of the sealing system.

- If your primary focus is experimental purity: Always operate the furnace with a slight positive pressure of your process gas to ensure any potential micro-leaks flow outward, preventing contamination.

- If your primary focus is long-term reliability: Confirm that the water-cooling system is active whenever the furnace is hot to protect the primary door seal from accelerated heat degradation.

- If your primary focus is consistent performance: Implement a schedule for regularly inspecting the door seal for signs of hardening or cracking, as this is the most common point of failure.

Ultimately, a disciplined approach to operating and maintaining the furnace's sealing system is the key to achieving repeatable, high-purity results.

Summary Table:

| Component | Function | Benefit |

|---|---|---|

| High-Temperature Silicone Rubber Seal | Creates airtight barrier on furnace door | Maintains flexibility and seal integrity during thermal expansion |

| Water-Cooling System | Circulates cool water to protect seals from heat | Prevents degradation, extends seal lifespan |

| Stainless Steel Flanges | Seals process tubes at ends | Allows easy sample access while isolating internal atmosphere |

| Positive Pressure Strategy | Maintains slight gas overpressure inside furnace | Prevents air ingress by forcing gas outflow through micro-leaks |

Ensure flawless experimental purity with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored options like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability precisely meets your unique sealing and experimental requirements. Contact us today to discuss how our furnaces can enhance your lab's reliability and performance!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

People Also Ask

- What are the key features of an atmosphere box furnace? Unlock Precise Heat Processing in Controlled Environments

- How does a mixed gas flow control system maintain stability during high-temperature nitriding? Precision Gas Ratios

- How does the pressure range change under vacuum conditions in an atmosphere box furnace? Explore Key Shifts for Material Processing

- What are some specific applications of atmosphere furnaces in the ceramics industry? Enhance Purity and Performance

- What is an atmosphere protection muffle furnace? Unlock Precise Heat Treatment in Controlled Environments